Method for preparing organic/inorganic composite nanowire filtering membrane

A composite nano-filtration membrane technology, which is applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve the problems of difficult nanofiber membranes and large membrane pore size, and achieve low cost, small pore size, and excellent preparation process. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] The preparation method of the organic / inorganic composite nanowire filter membrane comprises the following steps:

[0028] (1) Preparation of heparin solution:

[0029] Dissolving heparin sodium in a phosphate buffer solution with a pH value of 6.0-10 to obtain a heparin solution with a concentration of 0.2-2.5 g / L;

[0030] (2) Preparation of metal hydroxide nanowire solution:

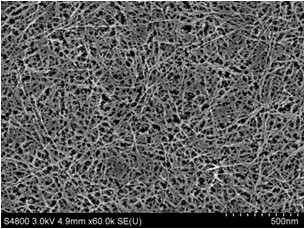

[0031] Dissolve 1 to 6 mmol / L metal salt in an equal volume of 0.4 to 2.4 mmol / L ethanolamine, stir magnetically for 1 minute, and grow for 1 to 30 days at 4 to 25 degrees Celsius to prepare clarified Transparent metal hydroxide nanowire solution;

[0032] (3) Preparation of core-shell structure composite nanowire solution:

[0033] Slowly add the heparin solution to the metal hydroxide nanowire solution, and stir it magnetically for 0.5 to 24 hours, so that the negatively charged heparin is fixed on the surface of the positively charged metal hydroxide nanowire by electrostatic action, form...

Embodiment 1

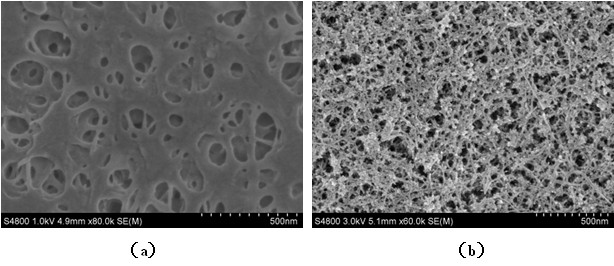

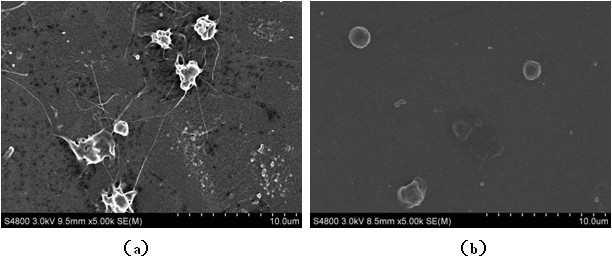

[0045]Dissolve heparin sodium in a phosphate buffer solution with a pH of 7.4 to obtain a heparin aqueous solution with a concentration of 0.2 to 2.5 g / L; dissolve 4 mmol / L copper nitrate trihydrate in an equal volume of 1.6 mmol / L In ethanolamine, magnetically stirred for 1 minute, and grown at 4-25 degrees Celsius for 1-7 days, a clear and transparent copper hydroxide nanowire solution was prepared; 0-7 milliliters of heparin solution was added to 40 milliliters of copper hydroxide nanowire solution , magnetically stirred for 0.5-3 hours to prepare a core-shell structure composite nanowire solution; cut out a polyvinylidene fluoride microfiltration membrane with a diameter of 5 cm, washed and dried, soaked in 95% ethanol for 1 hour, and deionized water Rinse 3 times, then fix it in the filter container with the membrane facing up, add 10-40 ml of the above core-shell structure composite nanowire solution into the container, filter under reduced pressure at 0.08-0.1 MPa; take ...

Embodiment 2

[0049] Dissolve heparin sodium in a phosphate buffer solution with a pH of 6 to obtain an aqueous heparin solution with a concentration of 1.0 to 2.5 g / L; dissolve 4 mmol / L copper nitrate trihydrate in an equal volume of 1.6 mmol / L In ethanolamine, magnetically stirred for 1 minute, and grown at 4-25 degrees Celsius for 3-30 days, a clear and transparent copper hydroxide nanowire solution was prepared; 0-20 milliliters of heparin solution was added to 40 milliliters of copper hydroxide nanowire solution , magnetically stirred for 1 to 5 hours to prepare a core-shell composite nanowire solution; cut a polysulfone ultrafiltration membrane with a diameter of 5 cm, wash and dry, soak in 95% ethanol for 1 hour, and rinse with deionized water for 3 times , then fix it in a filter container with the membrane facing up, add 10-60 ml of the above-mentioned core-shell structure composite nanowire solution into the container, filter under reduced pressure at 0.04-0.1 MPa; take it out, rin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com