Heat Sink and Electronic Device and Heat Exchanger Applying the Same

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036]The present invention will be apparent from the following detailed description, which proceeds with reference to the accompanying drawings, wherein the same references relate to the same elements.

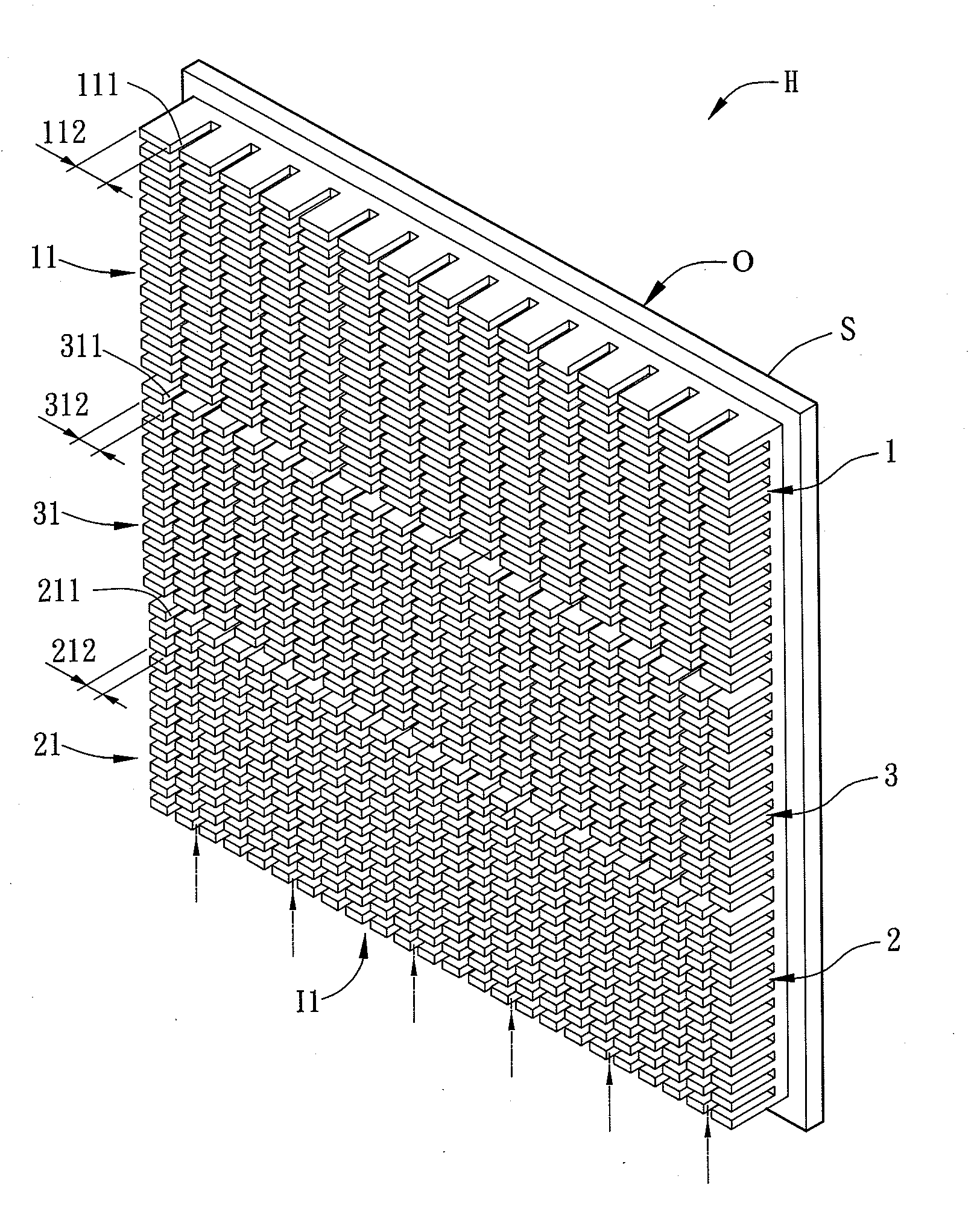

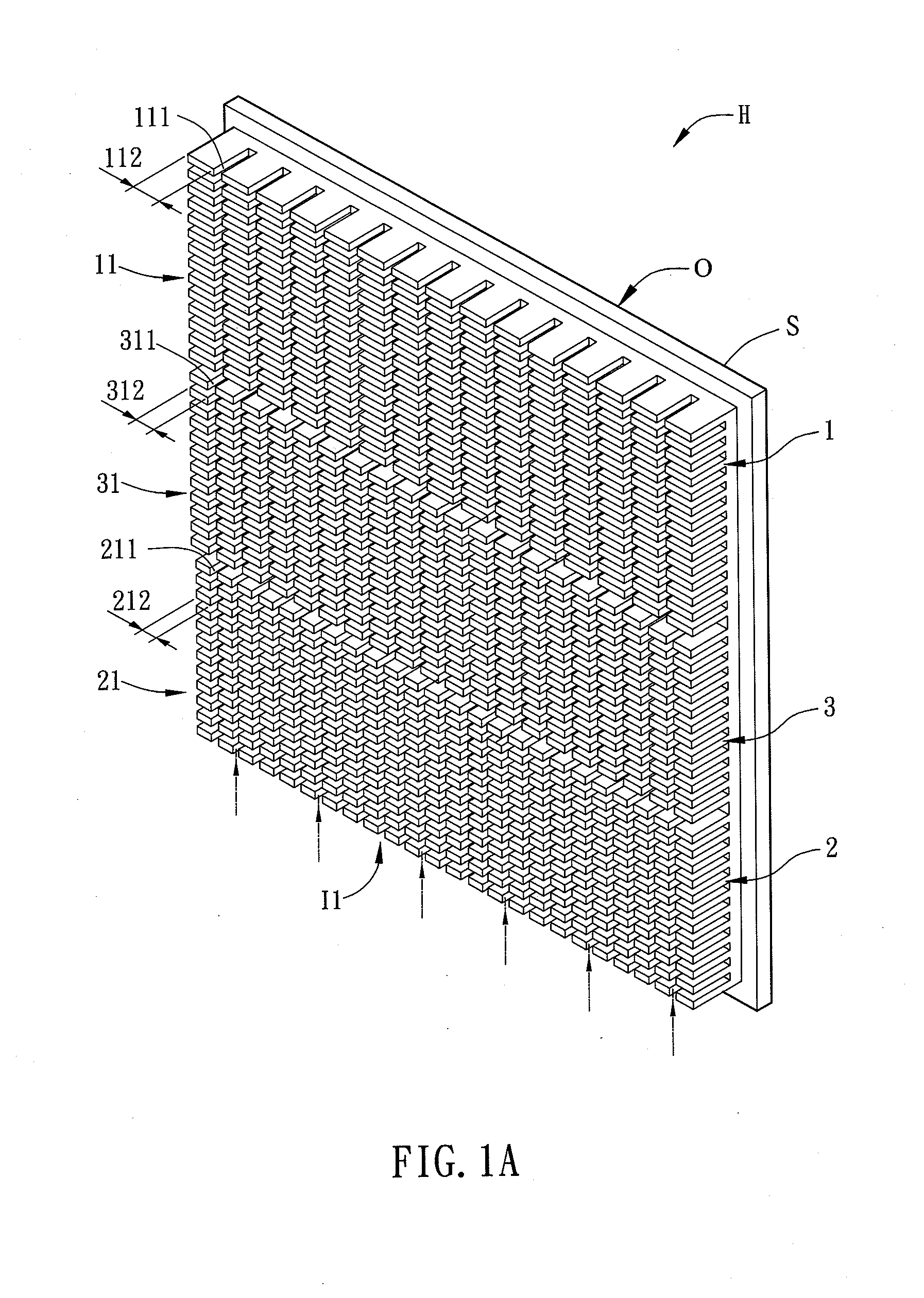

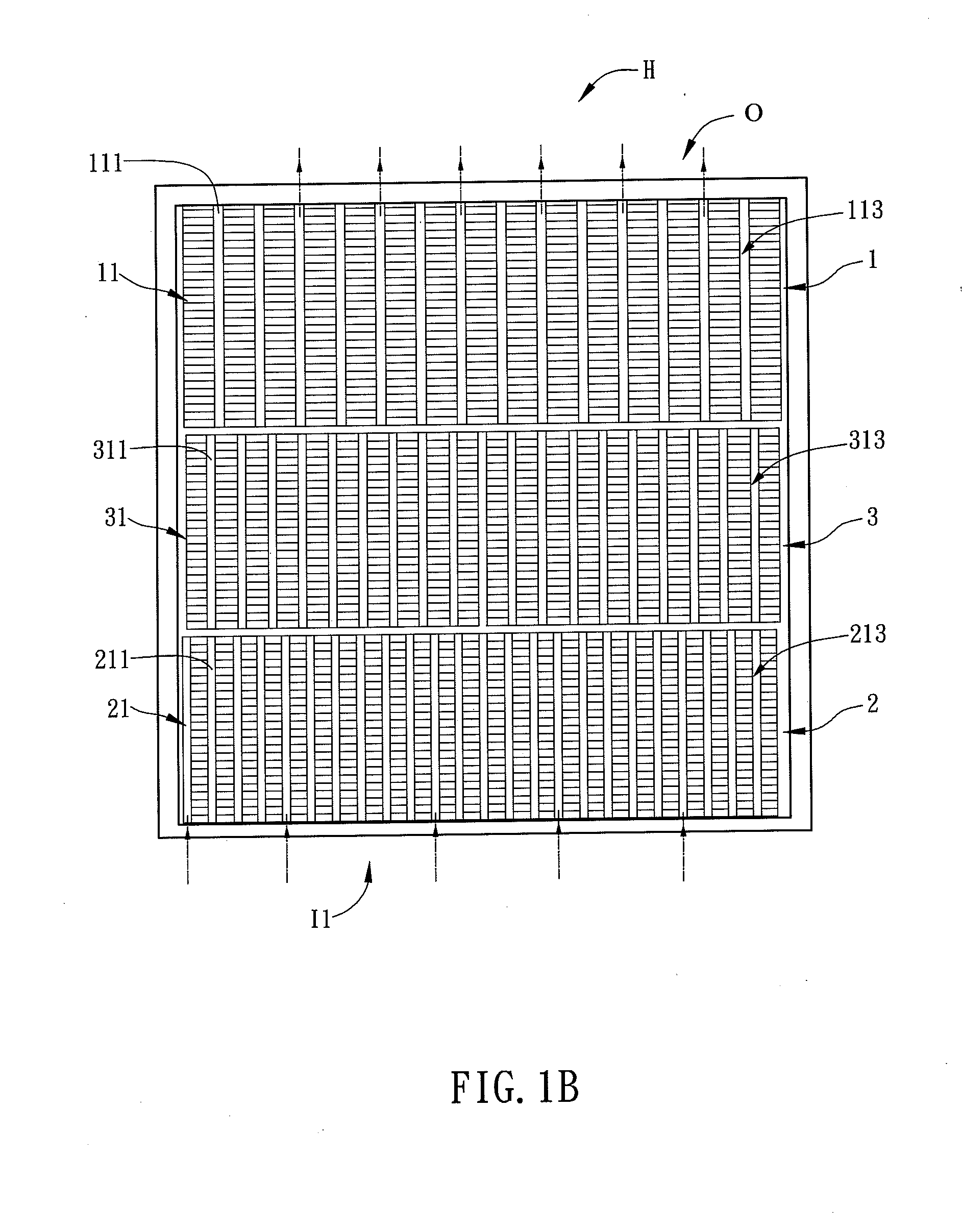

[0037]FIG. 1A is a schematic diagram showing a heat sink H according to an embodiment of the present invention, and FIG. 1B is a front view of the heat sink H of FIG. 1A. Referring to FIGS. 1A and 1B, the heat sink H includes a substrate S, at least a first fin set 1 and at least a second fin set 2. In order to achieve the desired heat dissipation, the heat sink H has a first inlet I1 and an outlet O, so that the air or gas can enter the first inlet I1, pass through the interior of the heat sink H to carry out the heat exchange, and then exit via the outlet O. The features of the structures of the heat sink H will be described hereinbelow.

[0038]The first fin set 1 and the second fin set 2 are all disposed on the substrate S. The first fin set 1 is located close to the outlet O, and at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com