Data acquisition and optimization method for laser processing of multiwave group holes

An optimization method and laser processing technology, applied in laser welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problem of special requirements that cannot realize multi-ring wave group hole data sorting, and achieve long programming time and high processing efficiency. , the effect of improving the collection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below in conjunction with accompanying drawing and embodiment the present invention is described in further detail:

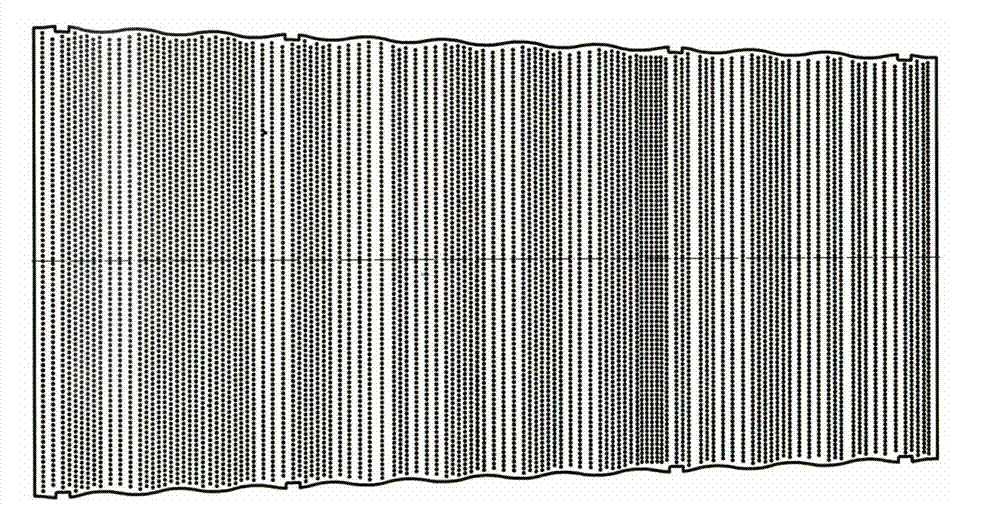

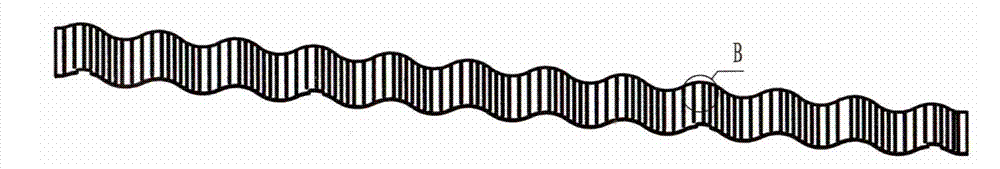

[0027]The data acquisition and optimization method for laser processing multi-wave group holes described in this embodiment, a small part of the part is intercepted, and hole B is taken as an example to illustrate. Five coordinate data are required for CNC machining of five coordinate equipment, that is, three point coordinates data and two rotation axis data, for the X, Y, Z coordinate data of the hole, that is, the X, Y, Z coordinate point of point B, the processing program can directly use the data in the ".txt" file, and the ".txt" The vector data, that is, the X vector data B1A1, the Y vector data B2A2, and the Z vector data B3A3, cannot be converted into the rotation axis data recognizable by the CNC equipment. Using the LASERDYNE-780 laser processing system, the C axis data is vector data in XY The angle between the plane projection and the X-axis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com