Filtering film processed through laser and laser processing system

A technology of laser processing and filter membrane, which is applied in the direction of dispersed particle filtration, laser welding equipment, metal processing equipment, etc., can solve the problems of limited particles, high production cost, complex structure, etc., and achieve high pore density, high processing efficiency, and quantity many effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] This embodiment provides a filter membrane processed by laser, on which a micropore array for filtering microparticles of different particle sizes is distributed, and in the micropore array, the diameter of the micropore is 0.1 μm-1 mm, It is preferably 2-500 μm. According to different requirements, the micropores can be laser-processed into different apertures. In this embodiment, the aperture of the micropores is preferably not greater than 2.5 μm, which is suitable for filtering PM2.5 and other micro particles. Its filtering effect is good, and it does not need to be stacked in multiple layers when used. The material of the filter membrane can be metal or non-metal material, wherein the metal material can be selected as conventional materials such as stainless steel or aluminum, and the non-metal material can be selected from plastic. Choose from different thicknesses. As an alternative embodiment, the filter membrane can also be a filter screen with different apert...

Embodiment 2

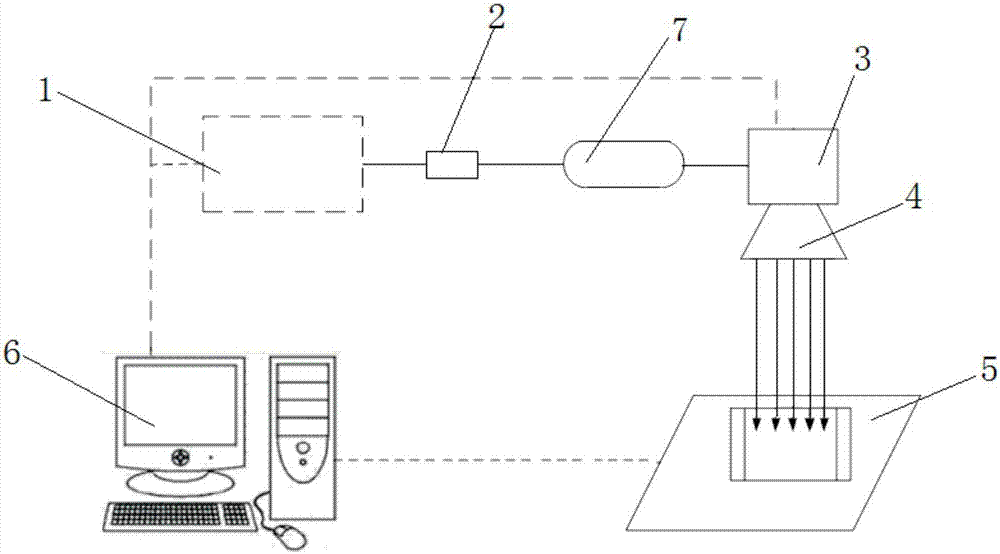

[0026] The present embodiment provides a kind of laser processing system for processing described filter membrane (net), it is as figure 1 As shown, it includes a laser 1 arranged in sequence along the laser optical path, a beam expander 2 for changing the diameter of the laser beam, a diffractive optical element (DOE) 7, a galvanometer unit 3 for deflecting the laser beam, and a laser beam for focusing The lens 4 and the object-carrying mechanism 5 of the beam, the object-carrying plane of the object-carrying mechanism 5 faces the light-emitting surface of the lens 4, and also includes a control device electrically connected with the laser 1, the vibrating mirror unit 3 and the object-carrying mechanism 4 Unit 6. The diffractive optical element 7 is arranged between the beam expander 2 and the vibrating mirror unit 3, and plays the role of diffracting the laser beam into multiple parallel beams, and can simultaneously form multiple micropores on the filter film or directly fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com