Frequency conversion bore distribution method for low-voltage anodic foil for aluminum electrolytic capacitor

A technology for aluminum electrolytic capacitors and low-voltage anode foils, applied in electrolytic capacitors, capacitors, circuits, etc., can solve problems such as powder loss and thinning, difficulty in uniform corrosion, and intensified dissolution, so as to save production costs, shorten corrosion time, and reduce discrete rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

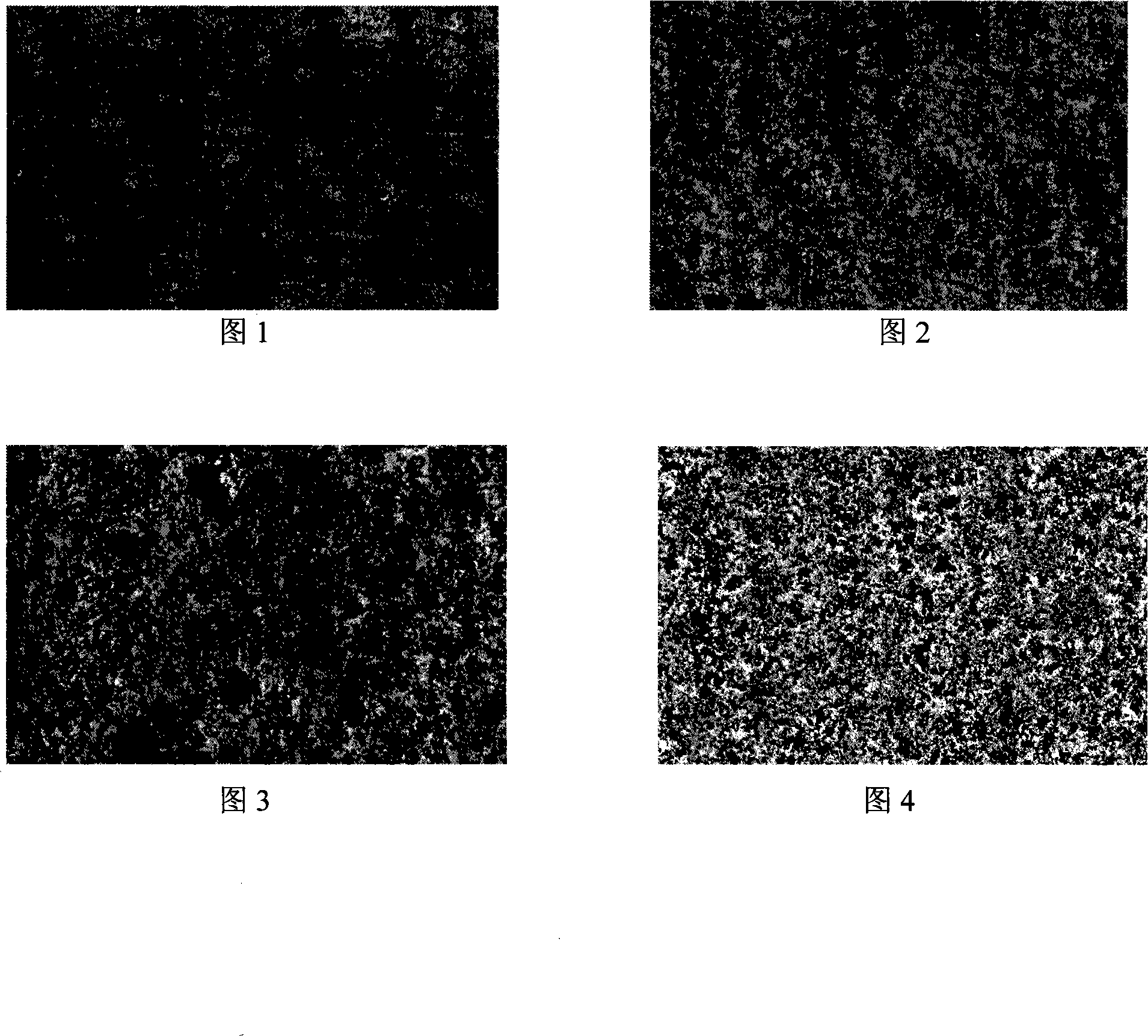

Image

Examples

Embodiment 1

[0024] After cleaning the surface of the aluminum electrolytic capacitor low-voltage anode foil with conventional degreasing and oxide film removal, put it into a 40°C corrosion solution of 3.6N hydrochloric acid, 0.2N sulfuric acid, and 1.2N aluminum trichloride, at a current density of 0.296A / cm 2 , Corrosion for 5s under the condition of frequency of 10Hz, and then corrode the holes according to the traditional process.

Embodiment 2

[0026] After cleaning the surface of the low-voltage anode foil of the aluminum electrolytic capacitor with routine degreasing and oxide film removal, put it into a 27°C corrosion solution of 2.7N hydrochloric acid, 0.08N sulfuric acid, and 0.56N aluminum trichloride, and the current density is 0.296A / cm 2 , Corrosion for 18s under the condition of frequency of 80Hz, and then corrode the holes according to the traditional process.

Embodiment 3

[0028] After cleaning the surface of the aluminum electrolytic capacitor low-voltage anode foil with conventional degreasing and oxide film removal, put it into a 38°C corrosion solution of 2.7N hydrochloric acid, 0.04N sulfuric acid, and 0.47N aluminum trichloride, at a current density of 0.363A / cm 2 , Corroded for 18s at a frequency of 5Hz, and then corroded according to the traditional process of hole expansion.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com