A method of making corroded foil

A manufacturing method and technology for corroding foils, applied in capacitors, circuits, electrical components, etc., can solve the problems of complex annealing heat treatment process, inability to realize automatic industrial production, and no practicability, and achieve uniform pore effect, convenient operation, and improvement. Effects of processing steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

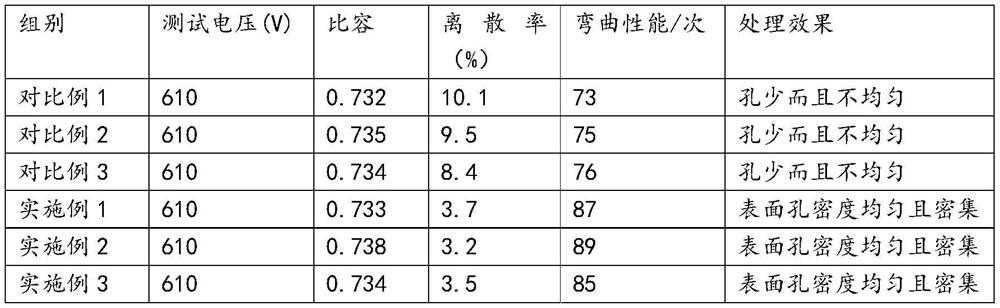

Examples

Embodiment 1

[0019] In an embodiment of the present invention, a method for manufacturing an etched foil includes five steps of pretreatment of high-purity aluminum foil, primary porosity corrosion, secondary porosity corrosion, hole expansion corrosion, and post-treatment. The pretreatment is Soak the aluminum foil in the pretreatment solution for 60s; after cleaning it, put it in the primary corrosion mixture at a temperature of 70°C, and apply a current density of 1500mA / cm 2 Electrolytic corrosion with direct current for 65s, cleaned with pure water, placed in a 10% hydrochloric acid solution, and chemically etched for 300s; finally cleaned with pure water and placed in an oven at 100°C for drying Just dry.

[0020] Wherein, the first-level porosity corrosion is to place the pretreated aluminum foil in a first-level porosity corrosion solution at a temperature of 70°C, and apply a current density of 1500mA / cm 2 The direct current was used to perform porosity corrosion for 65s, and the...

Embodiment 2

[0029] In an embodiment of the present invention, a method for manufacturing an etched foil includes five steps of pretreatment of high-purity aluminum foil, primary porosity corrosion, secondary porosity corrosion, hole expansion corrosion, and post-treatment. The pretreatment is Soak the aluminum foil in the pretreatment solution for 65s; after cleaning it, put it in the primary corrosion mixture with a temperature of 80°C, and apply a current density of 1800mA / cm 2 Perform electrolytic corrosion with direct current for 70s, clean it with pure water, put it into a 11% hydrochloric acid solution, and carry out chemical corrosion for 350s; finally clean it with pure water and put it in an oven with a temperature of 120°C for drying Just dry.

[0030] Wherein, the first-level porosity corrosion is to place the pretreated aluminum foil in a first-level porosity corrosion solution at a temperature of 80°C, and apply a current density of 1800mA / cm 2 The direct current was used to...

Embodiment 3

[0039] In an embodiment of the present invention, a method for manufacturing an etched foil includes five steps of pretreatment of high-purity aluminum foil, primary porosity corrosion, secondary porosity corrosion, hole expansion corrosion, and post-treatment. The pretreatment is Soak the aluminum foil in the pretreatment solution for 70s; after cleaning it, put it in the primary corrosion mixture with a temperature of 85°C, and apply a current density of 2100mA / cm 2 Perform electrolytic corrosion with direct current for 75s, clean it with pure water, put it into a 12% hydrochloric acid solution, and carry out chemical corrosion for 400s; finally clean it with pure water and put it in an oven with a temperature of 150°C for drying Just dry.

[0040] Wherein, the first-level porosity corrosion is to place the pretreated aluminum foil in a first-level porosity corrosion solution at a temperature of 85°C, and apply a current density of 2100mA / cm 2 The porosity corrosion was car...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com