Treatment device for alcohol production waste liquid

A technology for waste liquid treatment and alcohol, applied in filtration and separation, separation methods, chemical instruments and methods, etc., can solve the problems of cumbersome operation process, high content of suspended solids, incomplete solid-liquid separation of waste liquid, etc., and achieve simple operation process. , The equipment is safe and reliable, and the treatment effect is good.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

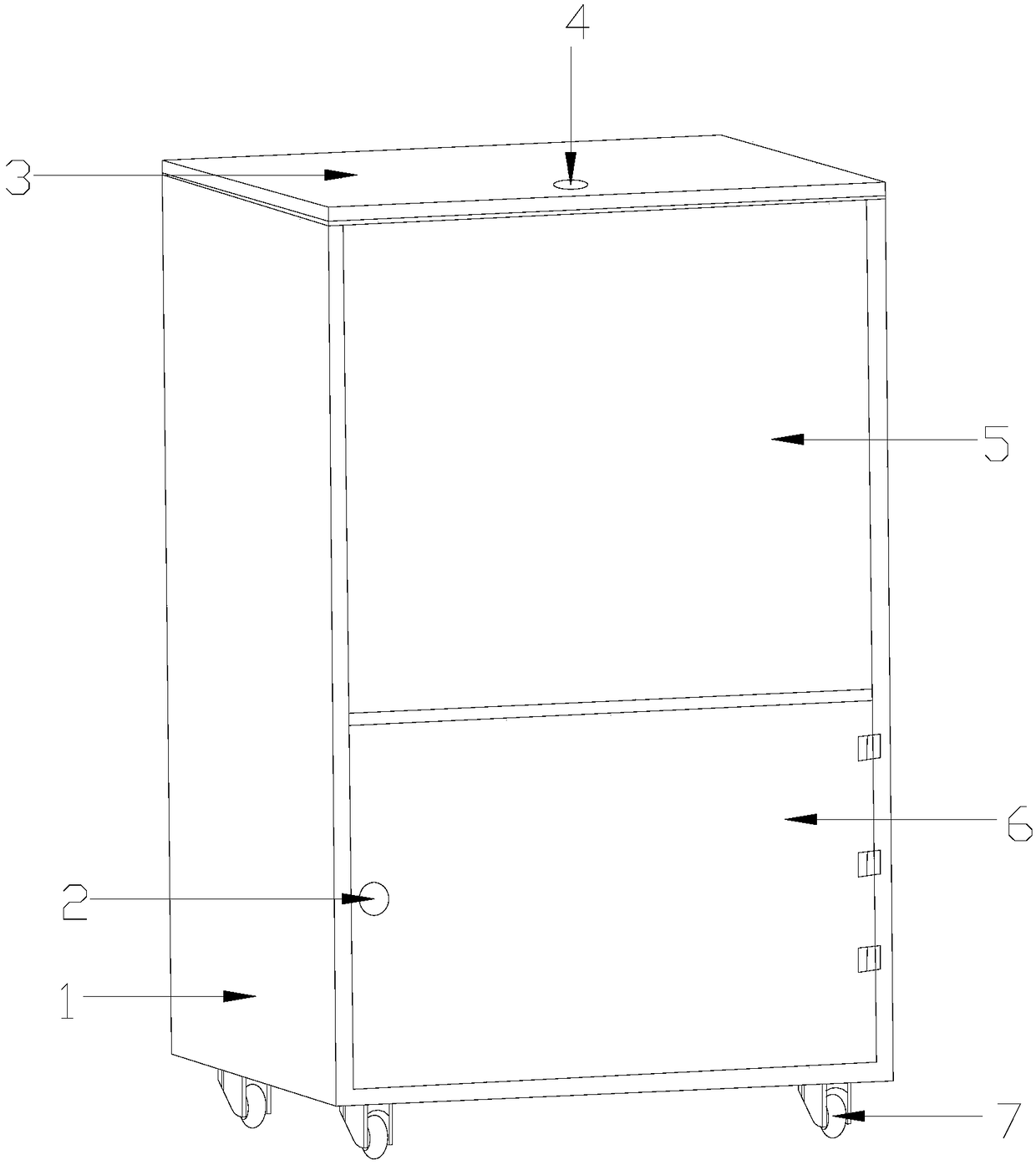

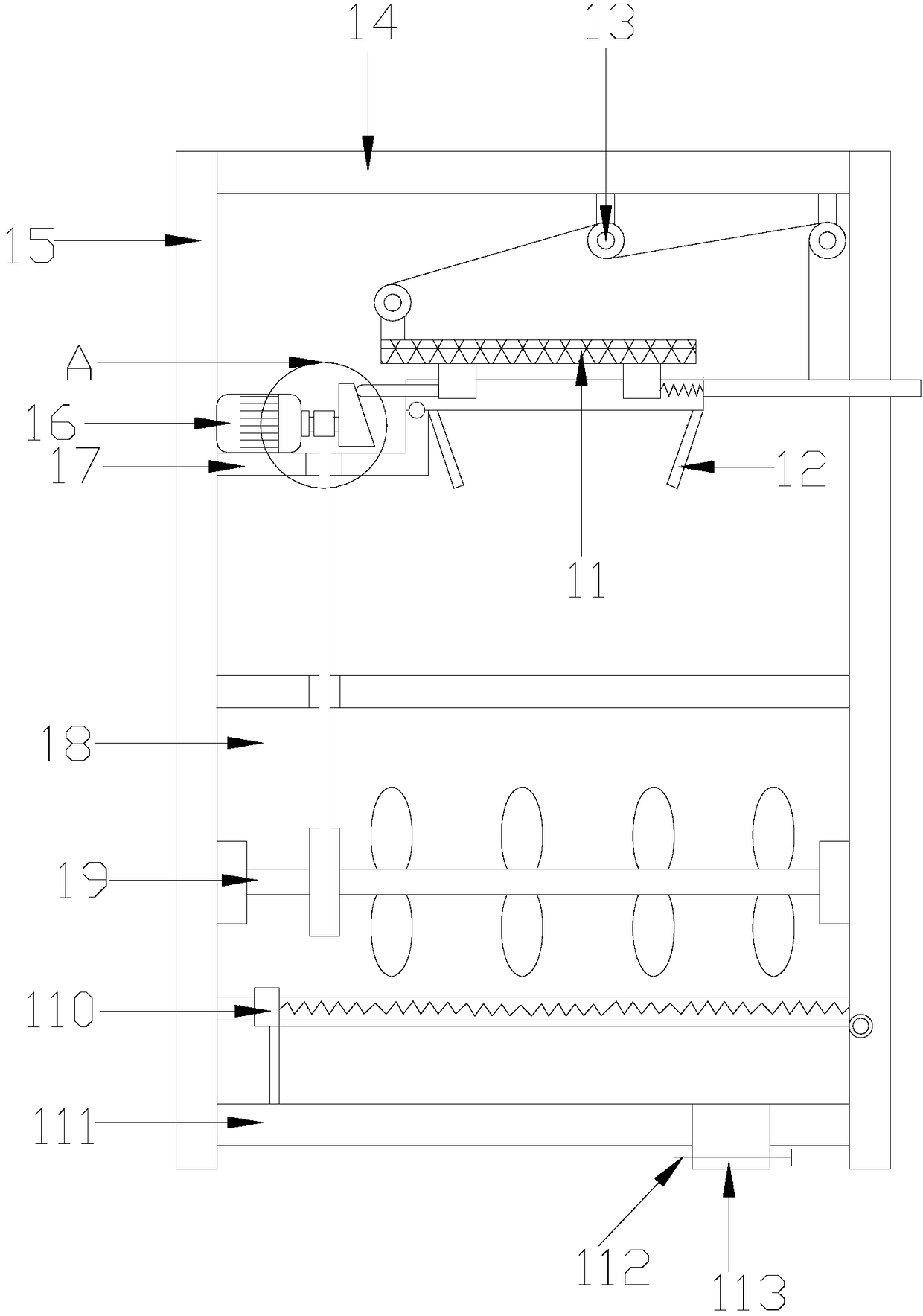

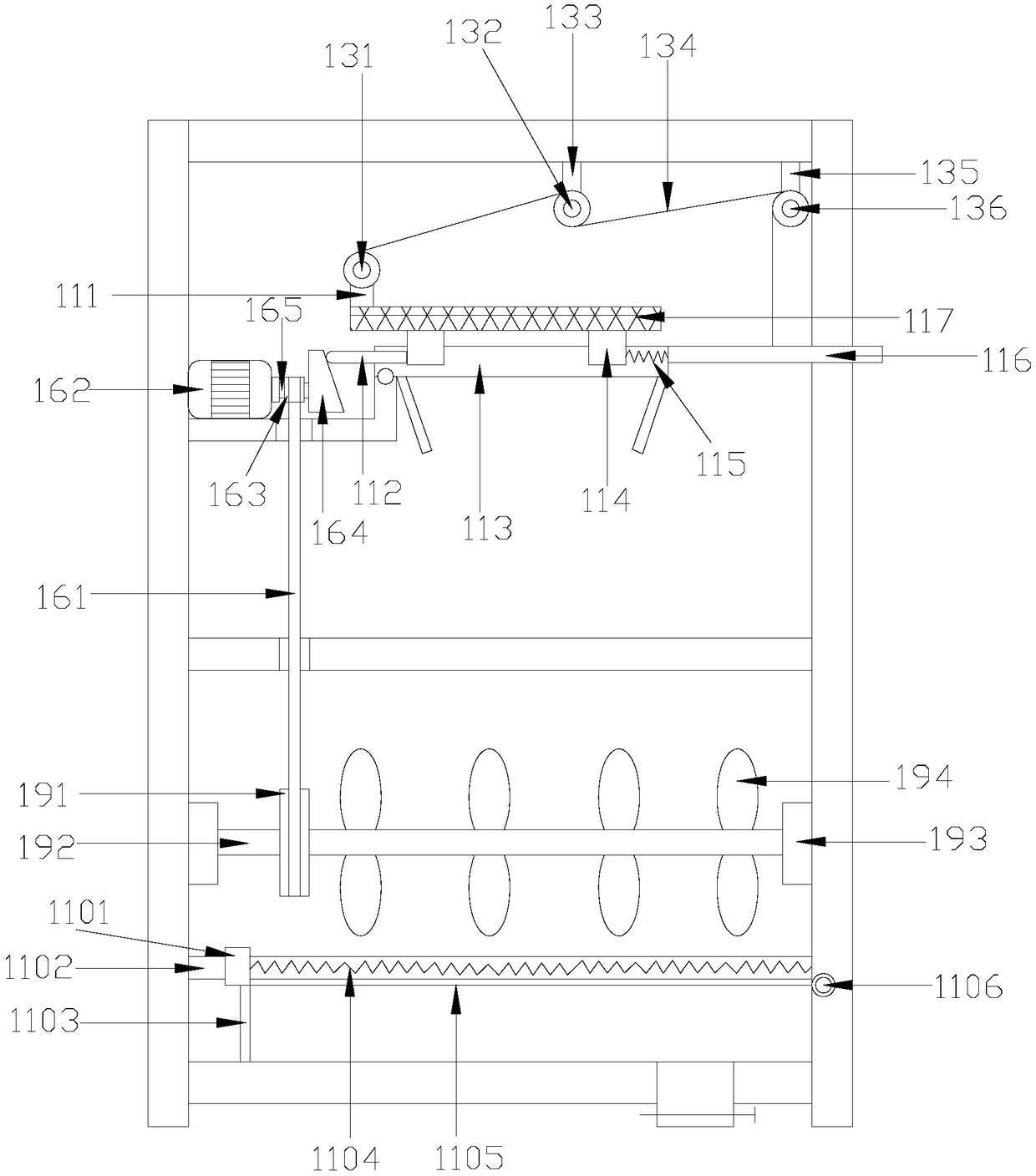

[0021] Such as Figure 1-Figure 5As shown, the present invention provides an alcohol production waste liquid treatment device, the structure of which includes a convenient waste liquid treatment mechanism 1, a connecting lock 2, an upper end cover 3, a built-in lock 4, a first closing plate 5, a second closing plate 6, and casters 7 The casters 7 are provided with more than two and the upper ends are respectively welded to the four corners of the bottom of the convenient waste liquid treatment mechanism 1, and the upper end cover 3 is fixedly fastened to the top of the convenient waste liquid treatment mechanism 1 and fixedly connected by connecting parts. The first closing plate 5 and the second closing plate 6 are rectangular structures, the first closing plate 5 and the second closing plate 6 are vertically fastened to the front end of the convenient waste liquid treatment mechanism 1 and fixedly connected by connecting parts, and the connecting lock 2. The rear end is fixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com