Liquid organic fertilizer, liquid organic fertilizer preparation device and liquid organic fertilizer preparation method

A preparation device and technology of organic fertilizer, applied in the fields of liquid organic fertilizer, liquid organic fertilizer preparation device, and liquid organic fertilizer preparation method, can solve the problems of low fertilizer production efficiency, increased manufacturing cost of liquid organic fertilizer, and large floor area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

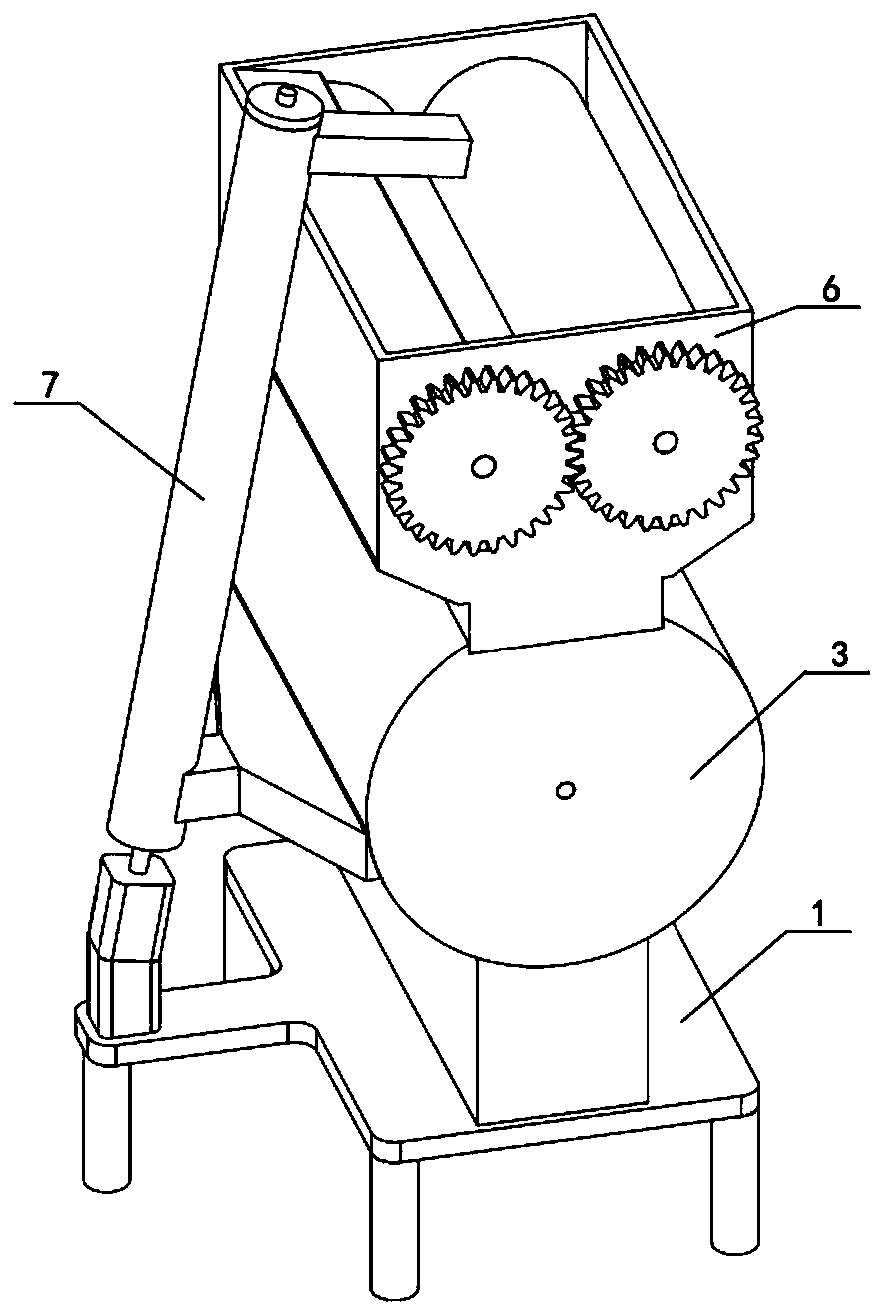

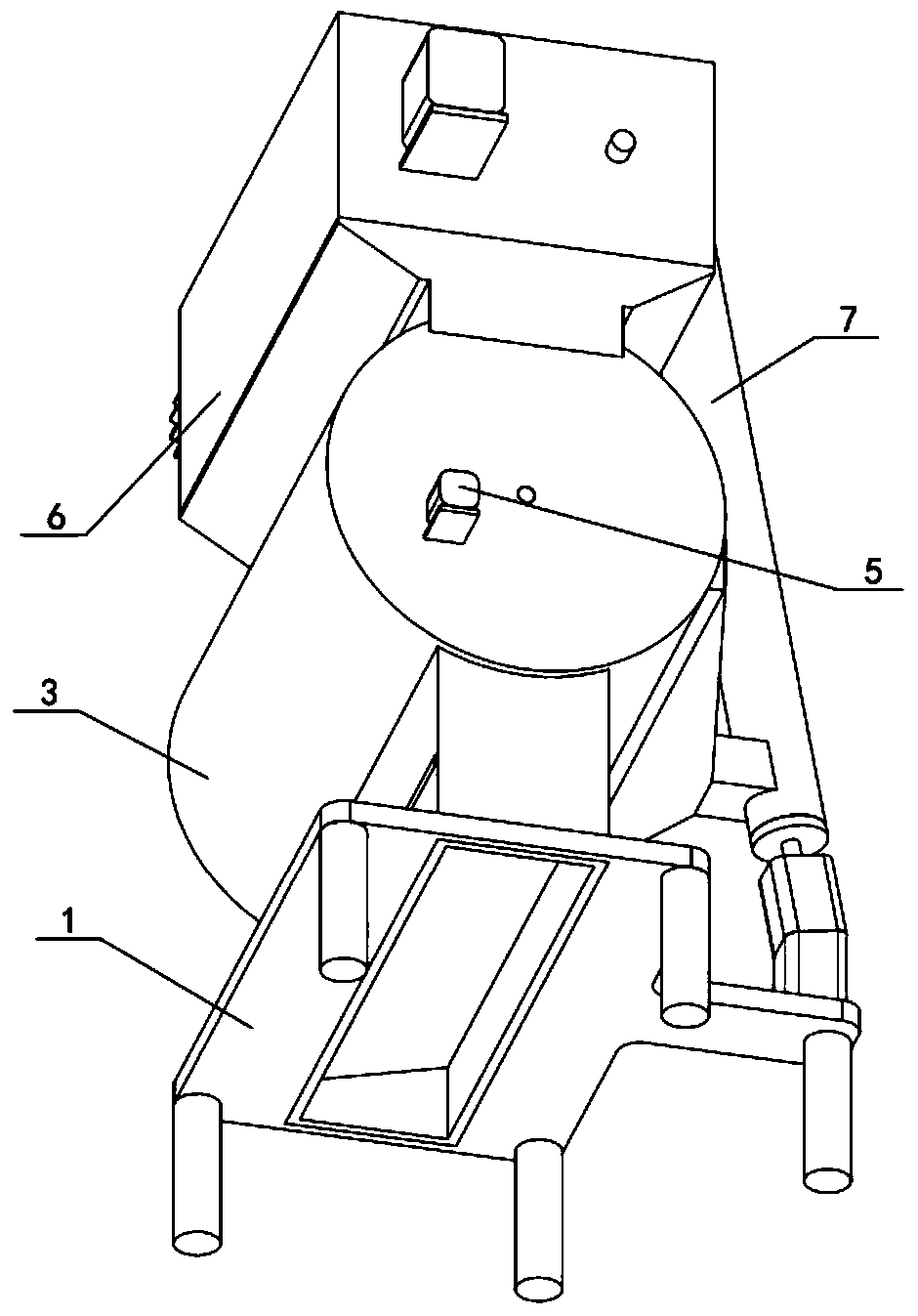

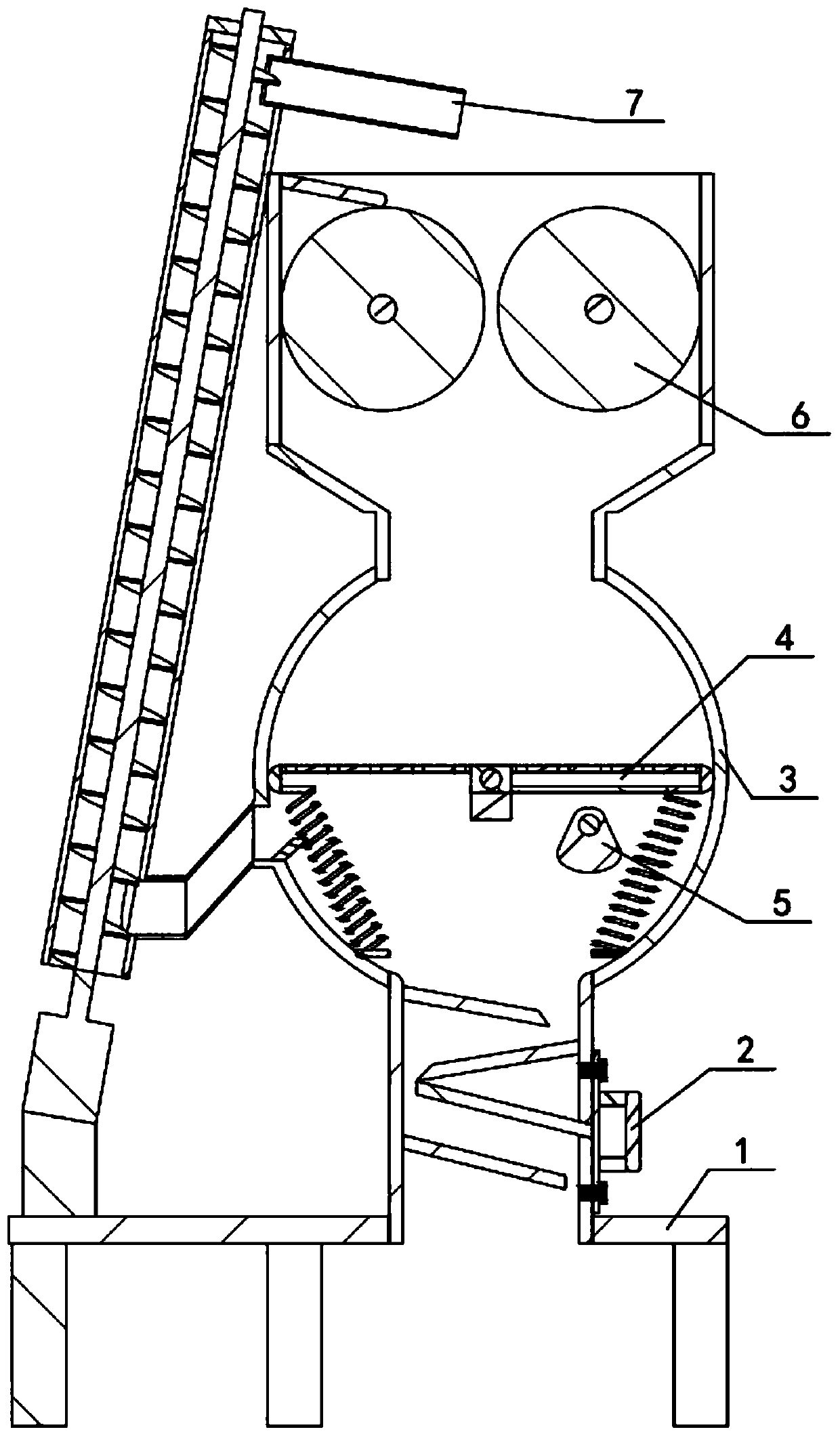

[0043] Such as Figure 1-14 As shown, the liquid organic fertilizer preparation device includes a magnetic adsorption treatment base 1, a magnetic adsorption device 2, a sieving chamber 3, a sieving device 4, a deflection oscillator 5, a crushing chamber 6 and a loop transporter 7. The magnetic adsorption treatment The base 1 is fixedly connected to the magnetic adsorber 2, the screening chamber 3 is fixedly connected to the upper end of the magnetic adsorption processing base 1, the sieve device 4 is connected to the screening chamber 3 in rotation, the biasing oscillator 5 is connected to the screening chamber 3, and the biasing oscillator 5 is located at the lower end of the right side of the screener 4, the crushing chamber 6 is fixedly connected to the upper end of the screening chamber 3, the lower and upper ends of the loop conveyor 7 are respectively fixedly connected with the magnetic adsorption treatment base 1 and the crushing chamber 6, and the loop conveyor The righ...

specific Embodiment approach 2

[0045] Such as Figure 1-14 As shown, the magnetic adsorption processing base 1 includes a base body 1-1, a processing chamber body 1-2, a socket 1-3, a linear slideway 1-4, a guide ladder 1-5, a deceleration plate 1-6, The expansion plate 1-7 and the bolt hole position I1-8, the upper end of the base body 1-1 is fixedly connected to the processing chamber body 1-2, the right side of the processing chamber body 1-2 is provided with a socket 1-3, and the processing chamber body 1-2 is provided with a linear slideway 1-4 on the inner end surfaces of the front and rear sides respectively, the guide ladder 1-5 is fixedly connected to the left side above the inner end of the processing chamber body 1-2, and the deceleration plate 1-6 is fixedly connected to the processing chamber body 1-2. The right side of the inner end of the chamber body 1-2, the expansion plate 1-7 is fixedly connected to the left side of the inner end of the processing chamber body 1-2, the guide ladder 1-5, t...

specific Embodiment approach 3

[0047] Such as Figure 1-14 As shown, the magnetic adsorber 2 includes an electromagnet 2-1, a limit slider body 2-2, a fixed connecting plate 2-3, a handle 2-4 and bolt holes II 2-5, and the electromagnet 2- The front and rear ends of 1 are respectively fixedly connected with a limit slider body 2-2, the right end of the electromagnet 2-1 is fixedly connected with the fixed connecting plate 2-3, and the right end of the fixed connecting plate 2-3 is fixedly connected with the handle 2-4, and the fixed Two bolt holes II 2-5 are set on the connecting plate 2-3; the two limit slider bodies 2-2 are respectively slidably connected in the two linear slideways 1-4, and the processing chamber body 1-2 The right end is located in the socket 1-3, and the fixed connecting plate 2-3 is fixedly connected with the right end of the processing chamber body 1-2 through two bolts, the two bolts pass through the two bolt holes II2-5 respectively, and the two bolts respectively The two bolt hol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com