Carbon nanometer tube array structure and growing method thereof

A carbon nanotube array, carbon nanotube technology, applied in nanotechnology, nanotechnology, nanotechnology for information processing, etc., can solve the problem of increasing the complexity of device design, difficult to achieve local multiple growth direction control, and limiting carbon Diversification and practicability of nanotube devices to achieve the effect of rich diversity and multiple choice spaces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

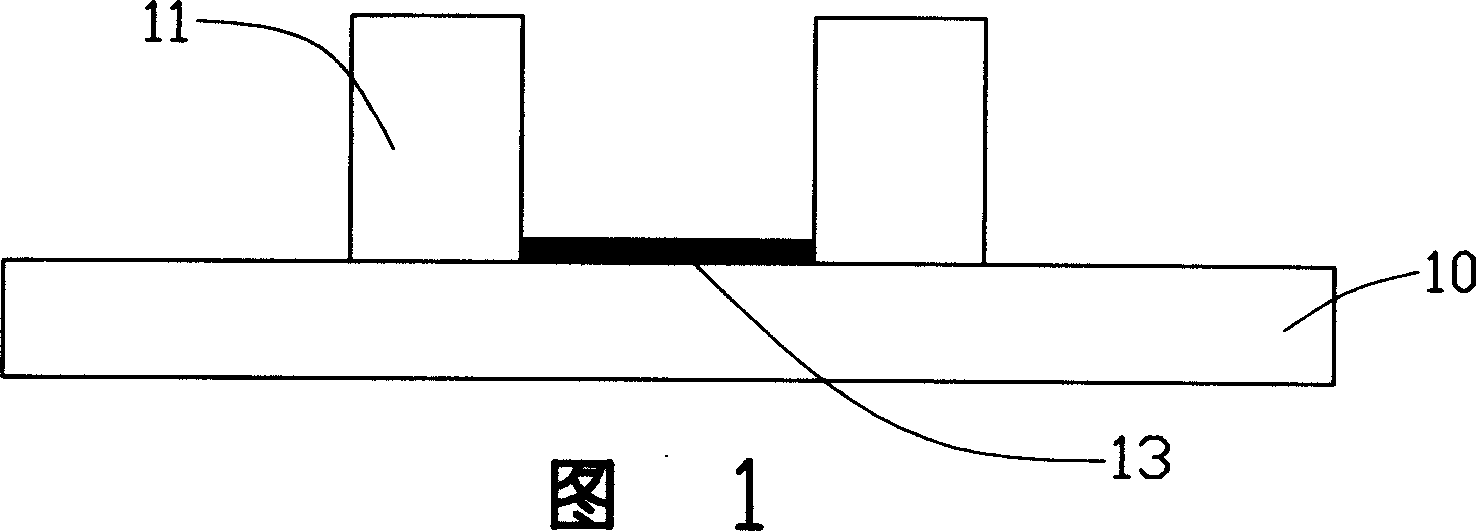

[0029] Referring to FIG. 1 , firstly, a substrate 10 is provided, and the substrate 10 is made of silicon, and a photoresist 11 is formed on the substrate 10 , and the photoresist 11 is formed into a predetermined pattern by photolithography. Deposit a catalyst 13 with a thickness of several nanometers at the position where carbon nanotubes need to be grown. The deposition method of the catalyst 13 can be thermal evaporation deposition method, or electron beam heating evaporation method and other methods can be used to cooperate with the photolithography process or pattern mask. The catalyst 13 The thickness is at least 2 to 3 nanometers, at most 10 nanometers, and the thickness needs to be uniform. The material can be iron, cobalt, nickel or their alloys. In the first embodiment, iron is selected as the material of the catalyst 13, and the deposited thickness is 6 nanometers.

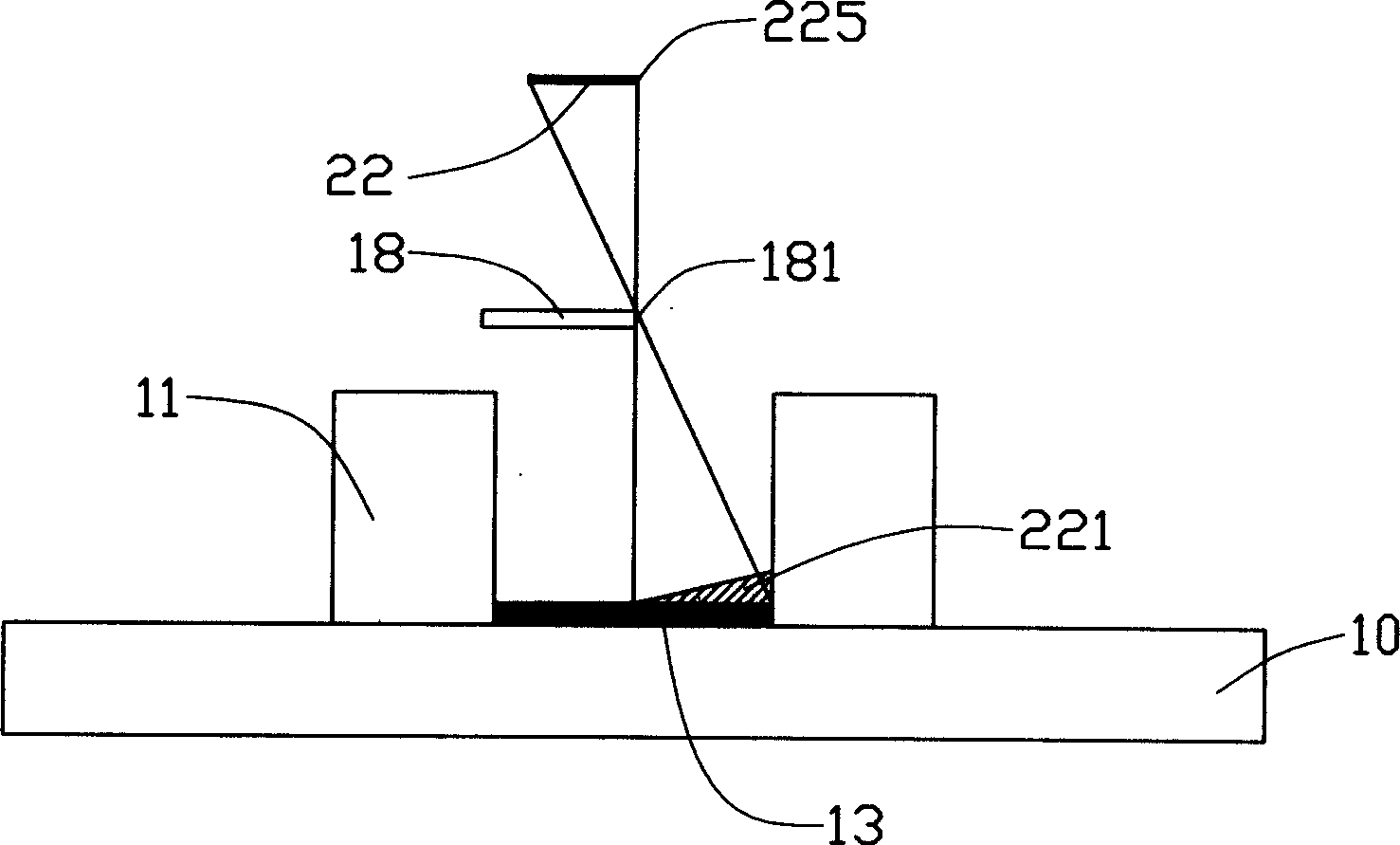

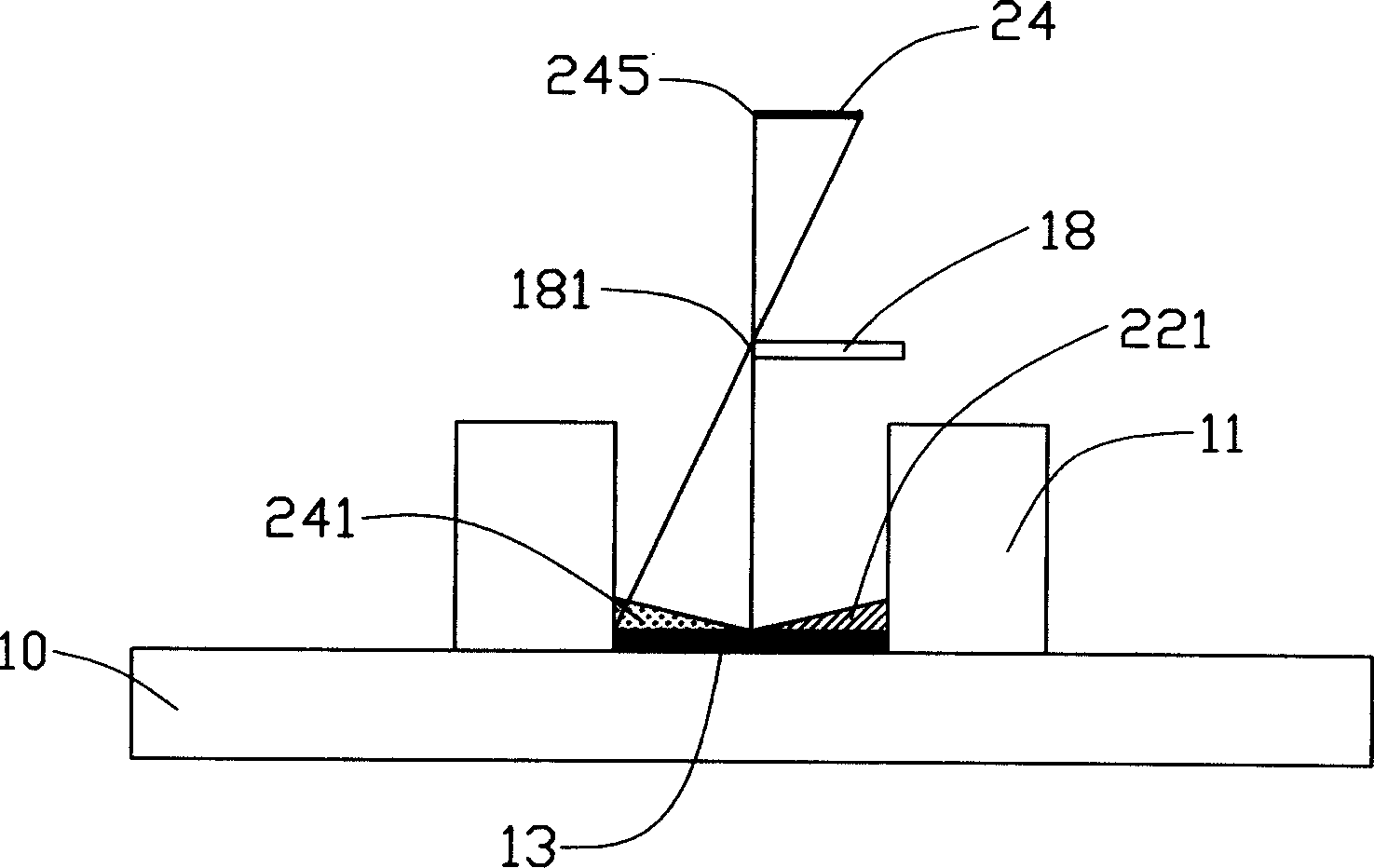

[0030] see figure 2 , deposit a layer of regulating material 221 that affects the growth rate of c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com