Alloy catalyst compositions and processes for making and using same

A composition and electrocatalyst technology, applied in the field of preparation and use of such compositions, alloy catalyst compositions, can solve the problems of reduced total activity, undesired agglomeration of alloy particles, unevenness between alloy particles and particles, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-15

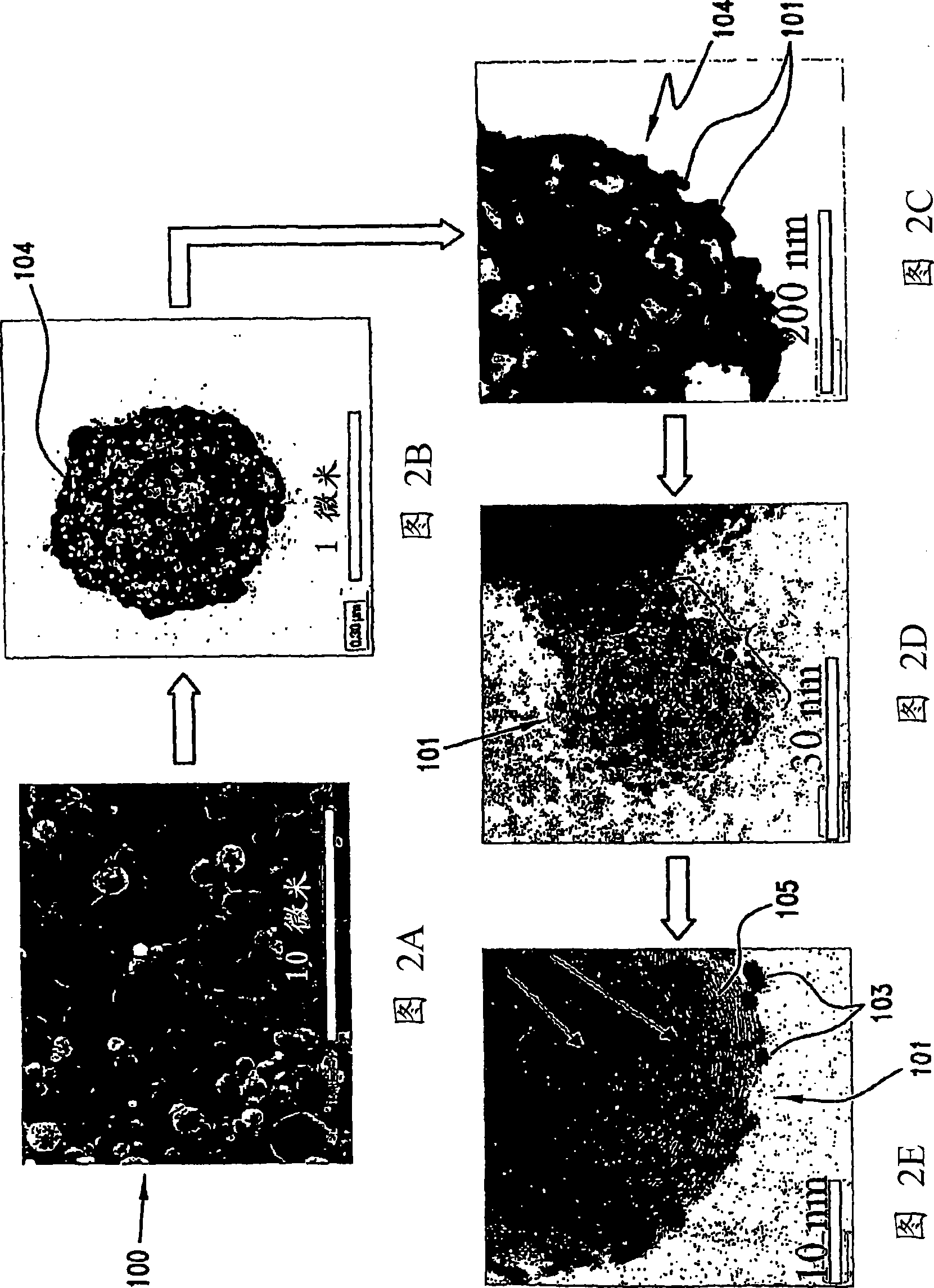

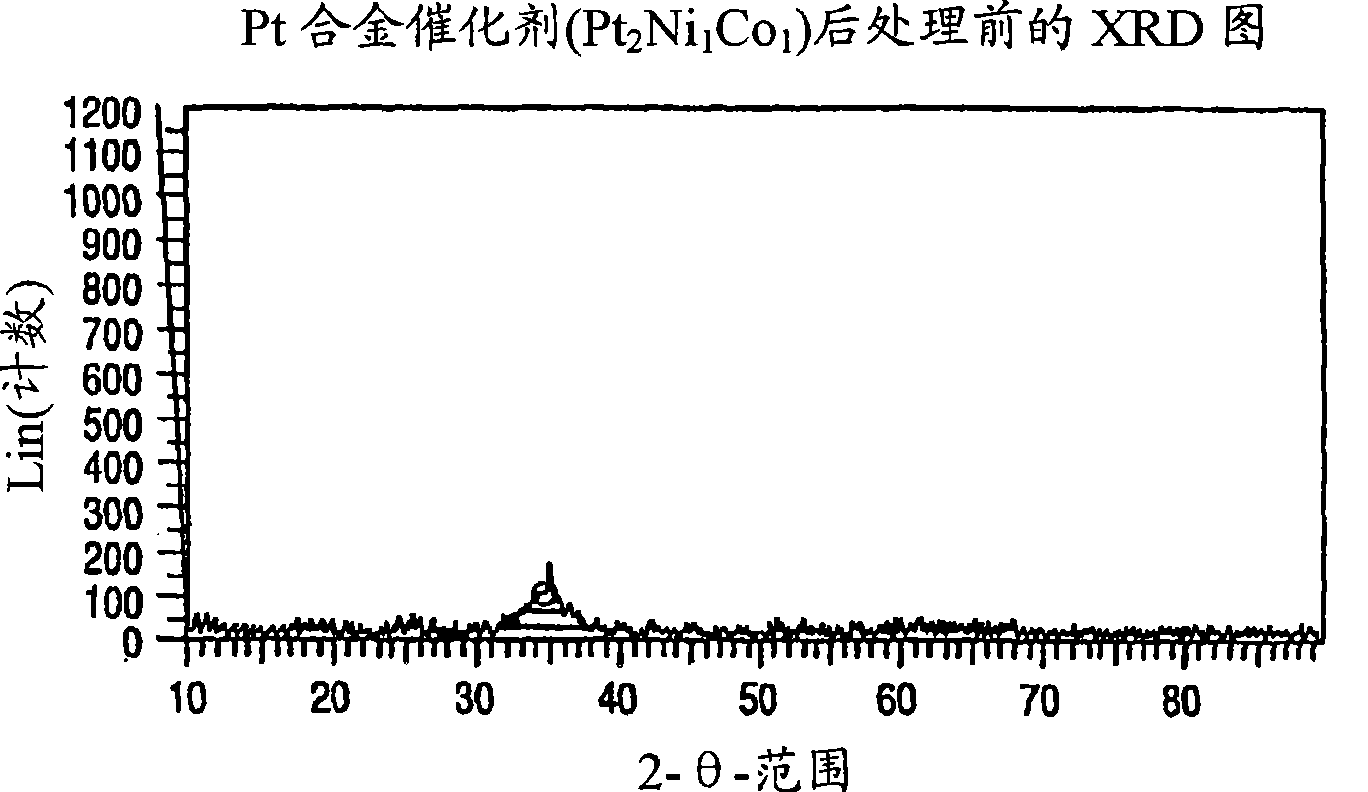

[0380] Synthesis of Pt-Co-Cu Alloy Nanoparticles on Carbon Matrix Particles

[0381] In Examples 1-15, electrocatalyst particles comprising platinum, cobalt and copper alloy nanoparticles disposed on a carbon matrix were synthesized according to one aspect of the present invention.

[0382] Specifically, 1.02 g of tetraammineplatinum nitrate, 0.64 g of cobalt nitrate hexahydrate, and 1.3 g of 5 / 2 hydrated copper nitrate were dissolved in 80 ml of distilled water, and then 18.2 g of 22% by weight Vulcan TM A carbon suspension of XC72R (available from Cabot Corporation) was added to the water. The resulting mixture is converted into an aerosol by means of an ultrasonic spray nozzle using air as a carrier gas in a spray conversion device such as a horizontal tubular reactor or a spray dryer. Aerosols were processed in a horizontal tube furnace set at a temperature of about 550°C, or alternatively produced on a spray dryer with an inlet temperature of about 580°C. obtained with ...

Embodiment 16-30

[0389] Synthesis of Pt-Co-Fe Alloy Nanoparticles on Carbon Matrix Particles

[0390] In Examples 16-30, electrocatalyst particles comprising platinum, cobalt and iron alloy nanoparticles disposed on a carbon matrix were synthesized according to one aspect of the present invention.

[0391] Specifically, 1.54 g of tetraammineplatinum nitrate, 0.58 g of cobalt nitrate hexahydrate and 0.34 g of ferric acetate were dissolved in 80 ml of distilled water, and then 18.2 g of 22% by weight Vulcan TM A carbon suspension of XC72R (available from Cabot Corporation) was added to the water. The resulting mixture is converted into an aerosol by means of an ultrasonic spray nozzle using air as a carrier gas in a spray conversion device such as a horizontal tubular reactor or a spray dryer. Aerosols were processed in a horizontal tube furnace set at a temperature of about 550°C or in a spray dryer with an inlet temperature of about 580°C. The composition obtained is 20% Pt 25 co 37 Fe 3...

Embodiment 31-45

[0398] Synthesis of Pt-Fe-Cu Alloy Nanoparticles on Carbon Matrix Particles

[0399] In Examples 31-45, electrocatalyst particles comprising platinum, iron and copper alloy nanoparticles disposed on a carbon substrate were synthesized according to one aspect of the present invention.

[0400] Specifically, 1.53 g of tetraammineplatinum nitrate, 0.34 g of iron acetate and 0.45 g of 5 / 2 hydrated copper nitrate were dissolved in 80 ml of distilled water, and then 18.2 g of 22% by weight Vulcan TM A carbon suspension of XC72R (available from Cabot Corporation) was added to the water. The resulting mixture is converted into an aerosol by means of an ultrasonic spray nozzle using air as a carrier gas in a spray conversion device such as a horizontal tubular reactor or a spray dryer. Aerosols were processed in a horizontal tube furnace set at a temperature of about 550°C or in a spray dryer with an inlet temperature of about 580°C. The composition obtained is 20% Pt 25 Fe 21 Cu ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com