A non-crystal alloy catalyst as well as its preparing method and purpose

A technology of amorphous alloys and catalysts, applied in the field of amorphous alloy catalysts and their preparation, can solve problems such as difficult product separation, low nanoparticle content, and unsuitability for practical applications, and achieve obvious catalytic effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] 1) 1.19g CoCl 2 ·6H 2 O and 5.0 g of polyethylene glycol were dissolved in 40 mL of deionized water, and 10 mL of cyclohexane was added, fully stirred and mixed to obtain an oil-in-water microemulsion.

[0021] 2) Add 10mL of 2.0mol / L KBH at 20°C 4 When the aqueous solution is added to the above-mentioned oil-in-water microemulsion, black particles are gradually formed in the solution, and gas emerges.

[0022] 3) The black particles formed above were washed successively with water and absolute ethanol for 3 to 5 times respectively to obtain a Co-B amorphous alloy sample, represented by Co-B-10.

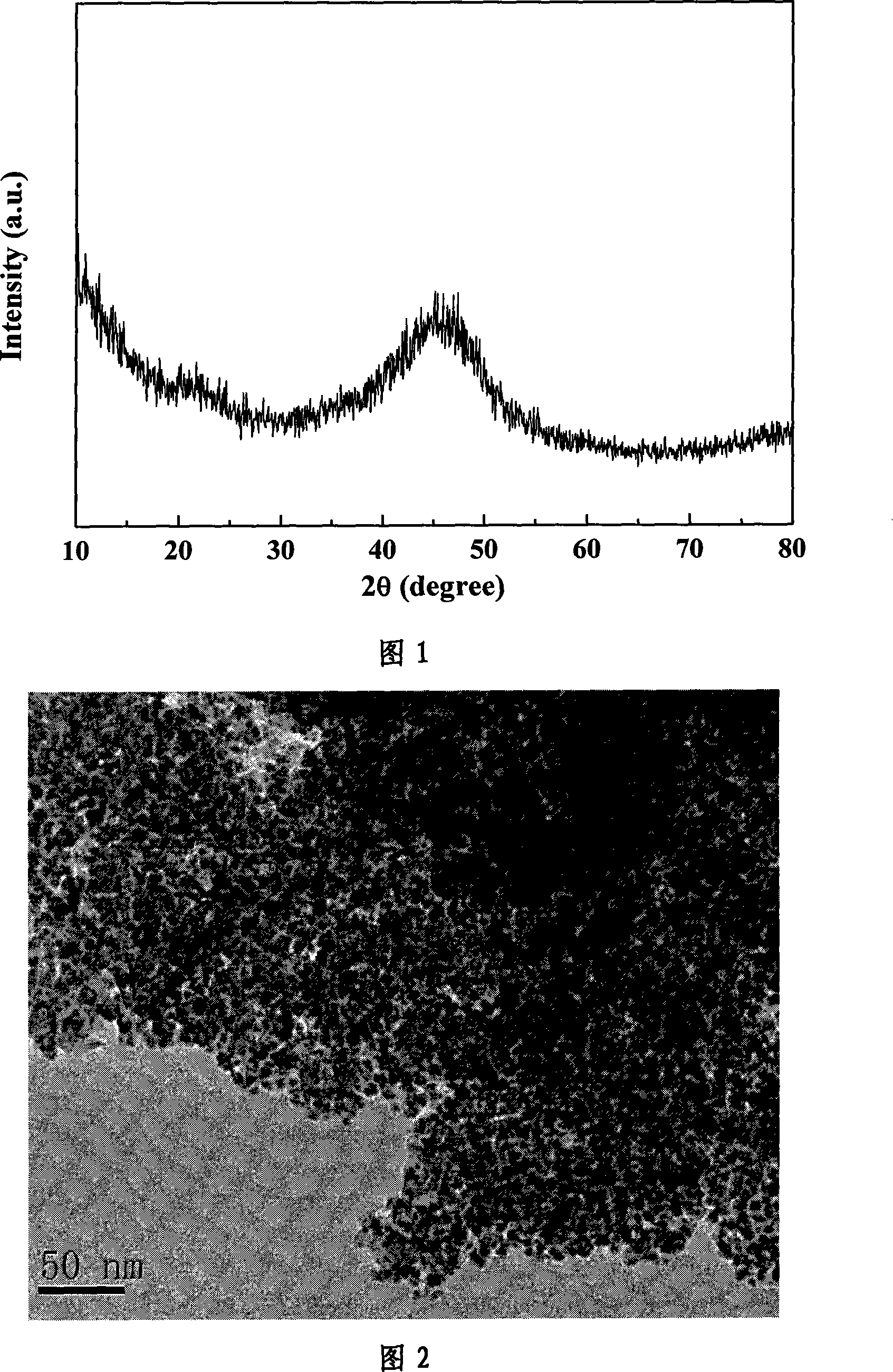

[0023] Fig. 1 is the XRD spectrogram of the sample prepared in this embodiment, the sample that can be determined from the diffuse peak shape of its about 45 ° position is amorphous; Fig. 2 is the TEM photo of the sample prepared in this embodiment, from photo It can be seen that the obtained sample is a spherical particle with a uniform particle size distribution, a smooth...

Embodiment 2

[0026] 1) 1.19g CoCl 2 ·6H 2 O and 5.0 g of polyethylene glycol were dissolved in 40 mL of deionized water, and 4 mL of cyclohexane was added, fully stirred and mixed to obtain an oil-in-water microemulsion.

[0027] 2) Add 10mL of 2.0mol / L KBH at 25°C 4 When the aqueous solution is added to the above-mentioned oil-in-water microemulsion, black particles are gradually formed in the solution, and gas emerges.

[0028] 3) The black particles formed above were washed successively with water and absolute ethanol for 3 to 5 times respectively to obtain a Co-B amorphous alloy sample, represented by Co-B-4.

[0029] The particle size of the sample prepared in this embodiment is 20nm.

[0030] The catalytic performance of the catalyst obtained in this example in the hydrogenation reaction of liquid-phase cinnamaldehyde to prepare cinnamyl alcohol is shown in Table 1.

Embodiment 3

[0032] 1) 1.19g CoCl 2 ·6H 2 O and 5.0 g of cetyltrimethylammonium bromide were dissolved in 40 mL of deionized water, and 8 mL of cyclohexylamine was added, fully stirred and mixed to obtain an oil-in-water microemulsion.

[0033] 2) Dissolve 15mL of 2.0mol / L NaBH at 0°C 4 When the aqueous solution is added to the above-mentioned oil-in-water microemulsion, black particles are gradually formed in the solution, and gas emerges.

[0034] 3) The black particles formed above were washed successively with water and absolute ethanol for 3 to 5 times respectively to obtain a Co-B amorphous alloy sample, represented by Co-B-8.

[0035] The particle size of the sample prepared in this embodiment is 10 nm.

[0036] The catalytic performance of the catalyst obtained in this example in the hydrogenation reaction of liquid-phase cinnamaldehyde to prepare cinnamyl alcohol is shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com