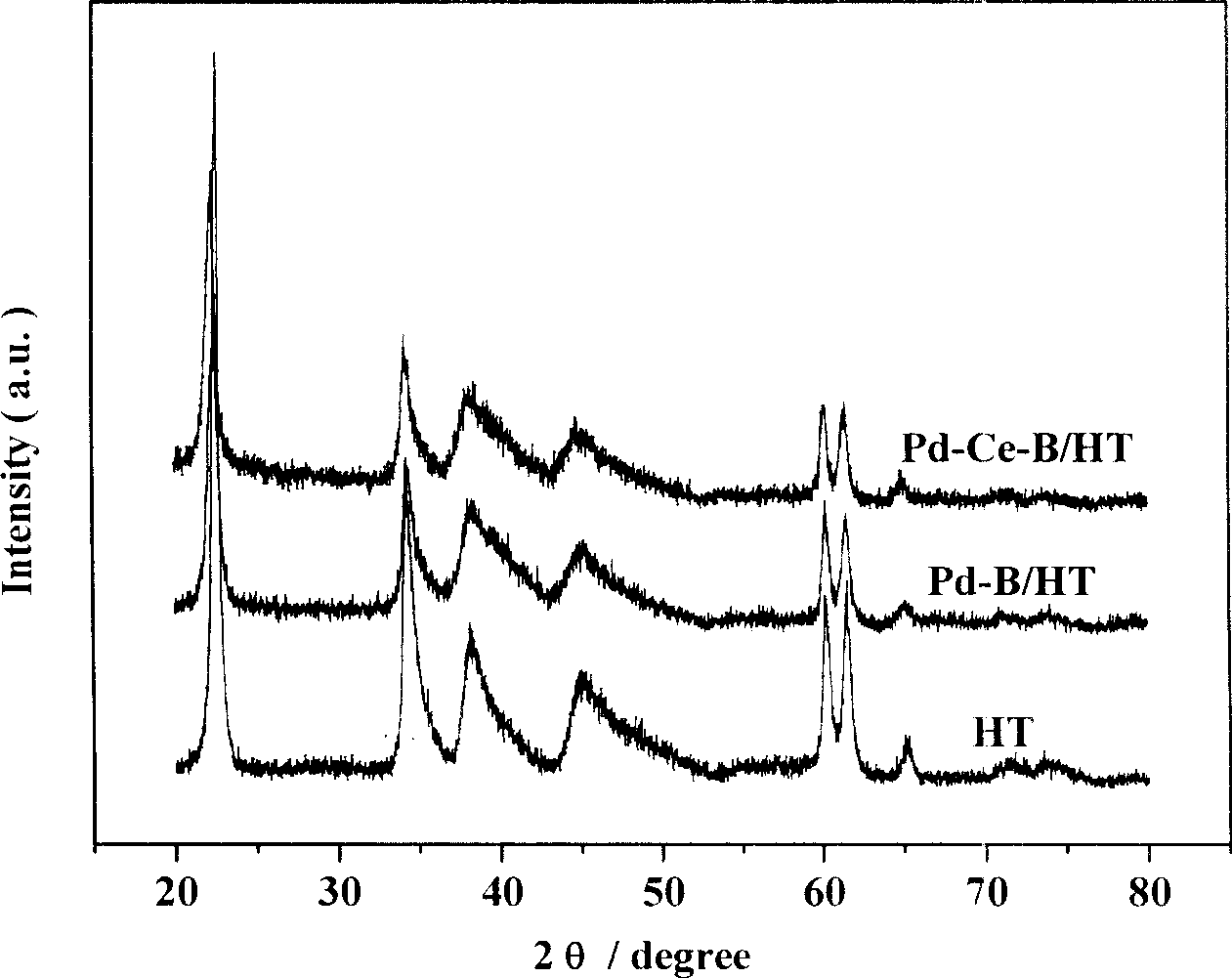

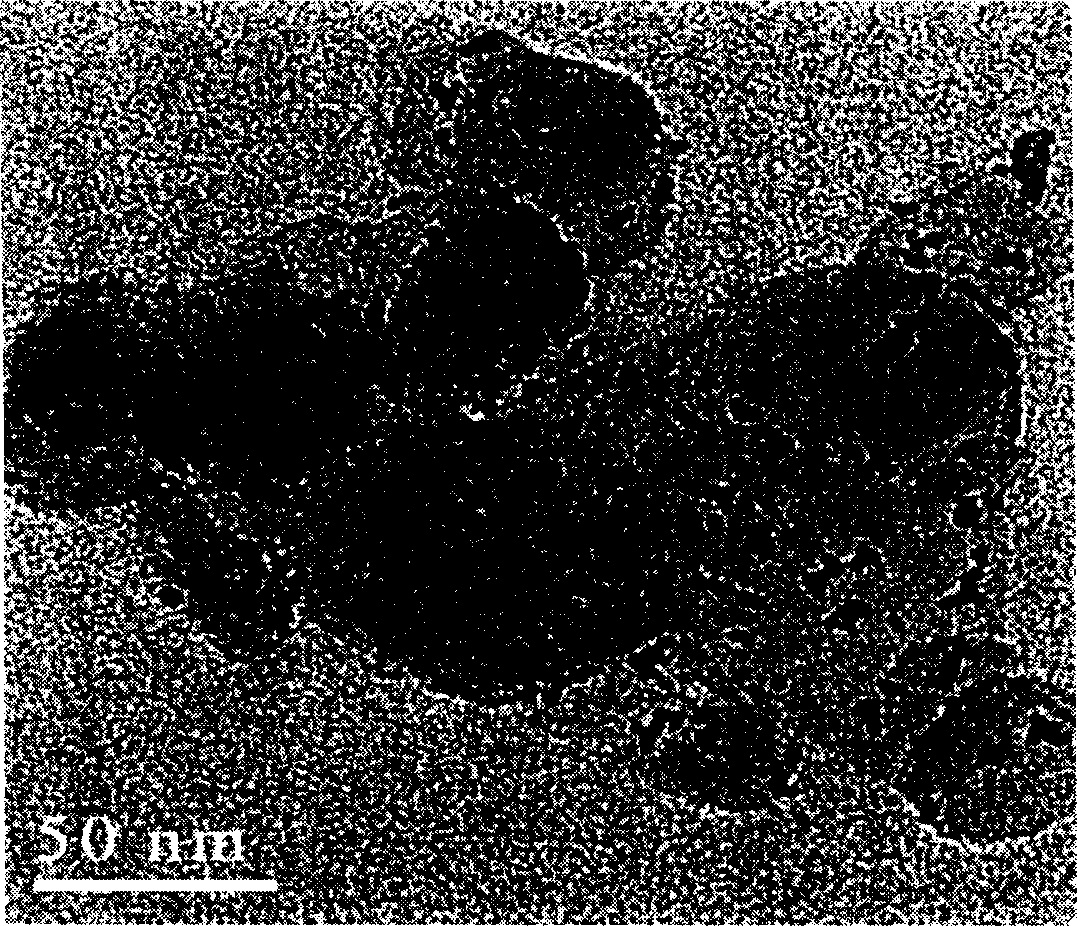

Load-type non-crystal-state alloy hydogenation catalyst and preparing method

A technology of amorphous alloys and hydrogenation catalysts, applied in the direction of metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problems of poor mechanical strength of catalysts, blockage of reactors, Broken and other problems, to achieve the effect of high selectivity and acquisition rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Step 1: A certain amount of Mg(NO 3 ) 2 , Al(NO 3 ) 3 (both are solid) dissolved in deionized water, dubbed C Mg(NO3)2 =1.43M,C Al(NO3)3 = 0.36M of clear solution A. A certain amount of NaOH, Na 2 CO 3 (both are solid) dissolved in deionized water, dubbed C NaOH =3.5M, C Na2CO3 = 0.94M of clear solution B.

[0026] Step 2: Take 700mL of solution A and slowly add it dropwise to 1000mL of solution B at 60°C, the control time is 1-2 hours, then continue to age at 60°C for 18 hours, filter while hot and wash until neutral, at 80°C Dry at -120°C to obtain a hydrotalcite carrier, which is ground for use.

[0027] Step 3: Weigh a certain amount of KBH 4 (solid) and NaOH, which are dissolved in deionized water together to form a 2.0M transparent solution, which is used as a reducing agent for subsequent use. Weigh a certain amount of PdCl 2 (solid) and Ce(NO 3 ) 3 (solid), dissolve them together in deionized water to form C Pd2+ = 0.28M, C Ce3+ =0.021M solution...

Embodiment 2

[0032] Step 1: Same as Step 1 in Example 1.

[0033] Step 2: Same as step 2 in Example 1.

[0034] Step 3: Same as Step 3 in Example 1.

[0035] Step 4: Weigh 1.0 g of hydrotalcite carrier, impregnate 1.0 mL of solution C overnight with an equal volume, and the rest of the steps are the same as Step 4 of Example 1.

[0036] Step 5: Same as Step 5 in Example 1 to obtain an amorphous alloy (Pd-Ce-B / HT-2) catalyst.

[0037] Step 6: Same as Step 6 in Example 1.

Embodiment 3

[0039] Step 1: Same as Step 1 in Example 1.

[0040] Step 2: Same as step 2 in Example 1.

[0041] Step 3: Same as Step 3 in Example 1.

[0042] Step 4: Weigh 1.0 g of hydrotalcite carrier, impregnate 1.5 mL of solution C overnight with an equal volume, and the remaining steps are the same as Step 4 of Example 1.

[0043] Step 5: Same as Step 5 in Example 1 to obtain an amorphous alloy (Pd-Ce-B / HT-3) catalyst.

[0044] Step 6: Same as Step 6 in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com