Low-platinum carbon-supported nanometer Pd-Pt alloy catalyst, and preparation method and application thereof

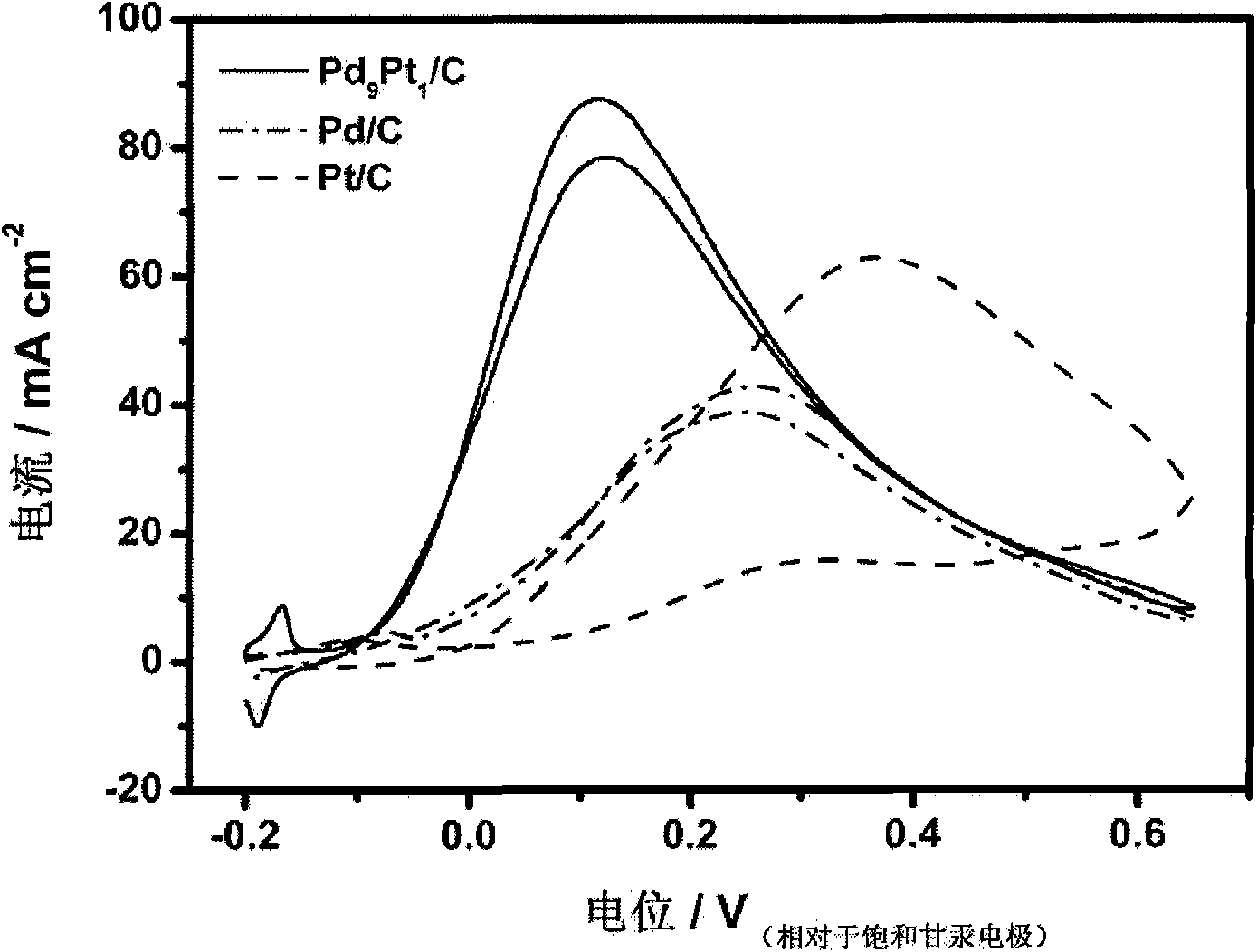

A technology of alloy catalyst and platinum carbon, which is applied in the field of electrochemical energy, can solve the problems of low activity, low utilization rate of precious metals, and poor catalytic stability, and achieve good dispersion, improved catalyst performance, and long-lasting catalytic stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

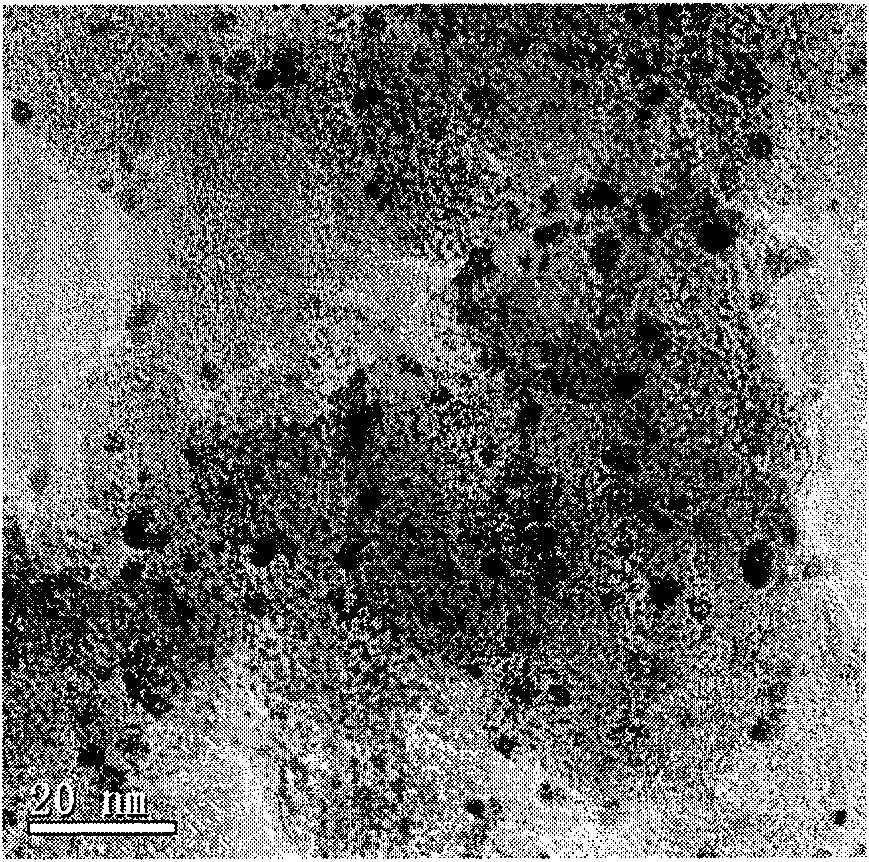

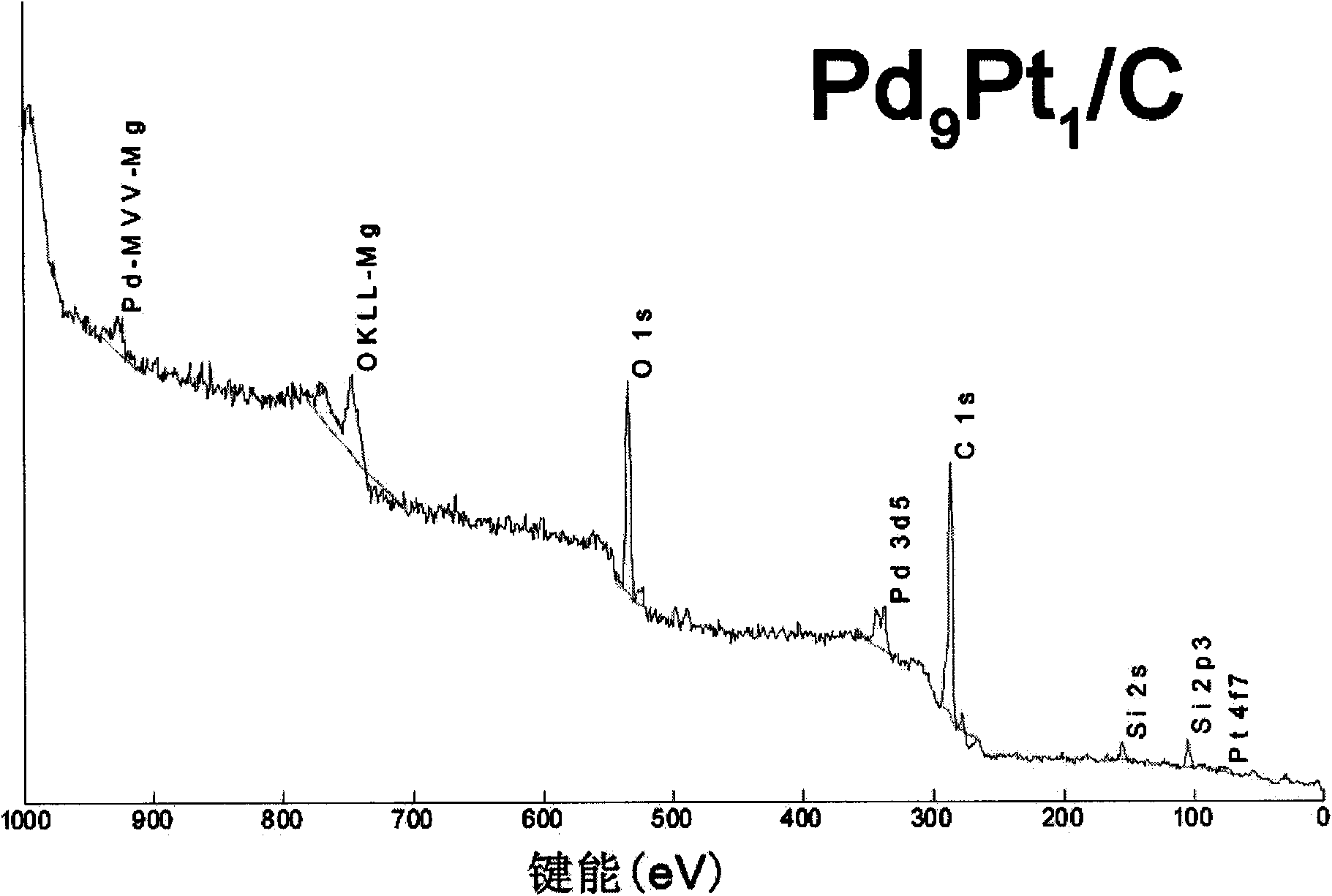

[0031] Take 20mL deionized water in a three-necked flask, and put 1050μL Na 2 PdCl 4 solution (0.05M), 456 μL K 2 PtCl 4 Solution (0.05M) and 753μL EDTA solution (0.1M) were added to it, the temperature was raised to 60°C, and the Pd and Pt metal ions were fully complexed after stirring well, then NaOH (0.1M) solution was added dropwise to adjust the pH value of the mixture to 10. Add 32 mg of dry pretreated XC-72 activated carbon into the three-necked flask, disperse by ultrasonic vibration for 0.5 h, and then strengthen stirring for 0.5 h, so that the complex of metal ions is evenly dispersed on the surface of the carbon, and the raw carbon slurry is obtained. During the stirring process, high-purity Ar gas was introduced to remove dissolved oxygen until the subsequent reduction reaction was completed.

[0032] Dissolve 36 g of sodium borohydride in 12 mL of Na 2 CO 3 (0.5M) solution, use a peristaltic pump to control the flow rate of 0.1mL / min to drop into the above-me...

Embodiment 2

[0035] Take 20mL deionized water in a three-necked flask, and put 1050μL Na 2 PdCl 4 solution (0.05M), 456 μL K 2 PtCl 4 Solution (0.05M) and 753 μL sodium citrate solution (0.1M) were added to it, the temperature was raised to 40°C, and the Pd and Pt metal ions were fully complexed after being fully stirred, then NaOH (0.1M) solution was added dropwise to adjust the pH of the mixture When the value reaches 11, add 32 mg of dry pretreated XC-72 activated carbon into the three-necked flask, disperse by ultrasonic vibration for 0.5 h, and then strengthen stirring for 0.5 h, so that the complex of metal ions is evenly dispersed on the surface of the carbon, and the raw carbon slurry is obtained. , During the process of dispersing and stirring, high-purity Ar gas was introduced to remove the dissolved oxygen until the subsequent reduction reaction was completed.

[0036] Dissolve 50 g of ascorbic acid in 12 mL of Na 2 CO 3 (0.5M) solution, use a peristaltic pump to control th...

Embodiment 3

[0039] Take 20mL deionized water in a three-necked flask, and put 1354μL Na 2 PdCl 4 solution (0.05M), 152 μL K 2 PtCl 4 Solution (0.05M) and 753μL ethylenediamine solution (0.1M) were added to it, the temperature was raised to 40°C, and the Pd and Pt metal ions were fully complexed after stirring fully, then NaOH (0.1M) solution was added dropwise to adjust the pH of the mixture When the value reaches 10, add 32mg of dry pretreated XC-72 activated carbon into the three-necked flask, disperse by ultrasonic vibration for 0.5h, and then strengthen stirring for 0.5h, so that the complex of metal ions is evenly dispersed on the surface of the carbon, and the raw carbon slurry is obtained. , During the process of dispersing and stirring, high-purity Ar gas was introduced to remove the dissolved oxygen until the subsequent reduction reaction was completed.

[0040] Dissolve 50 g of ascorbic acid in 12 mL of Na 2 CO 3 (0.5M) solution, use a peristaltic pump to control the flow r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Central particle size | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com