Amorphous skeletal-nickel hydrogenating catalyst for anthraquinone process of preparing hydrogen peroxide and its prepn

A kind of hydrogen peroxide and catalyst technology, applied in the field of a new type of catalyst for hydrogenation of anthraquinone and its preparation field, can solve the problems of high production cost of hydrogen peroxide, expensive palladium catalyst and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

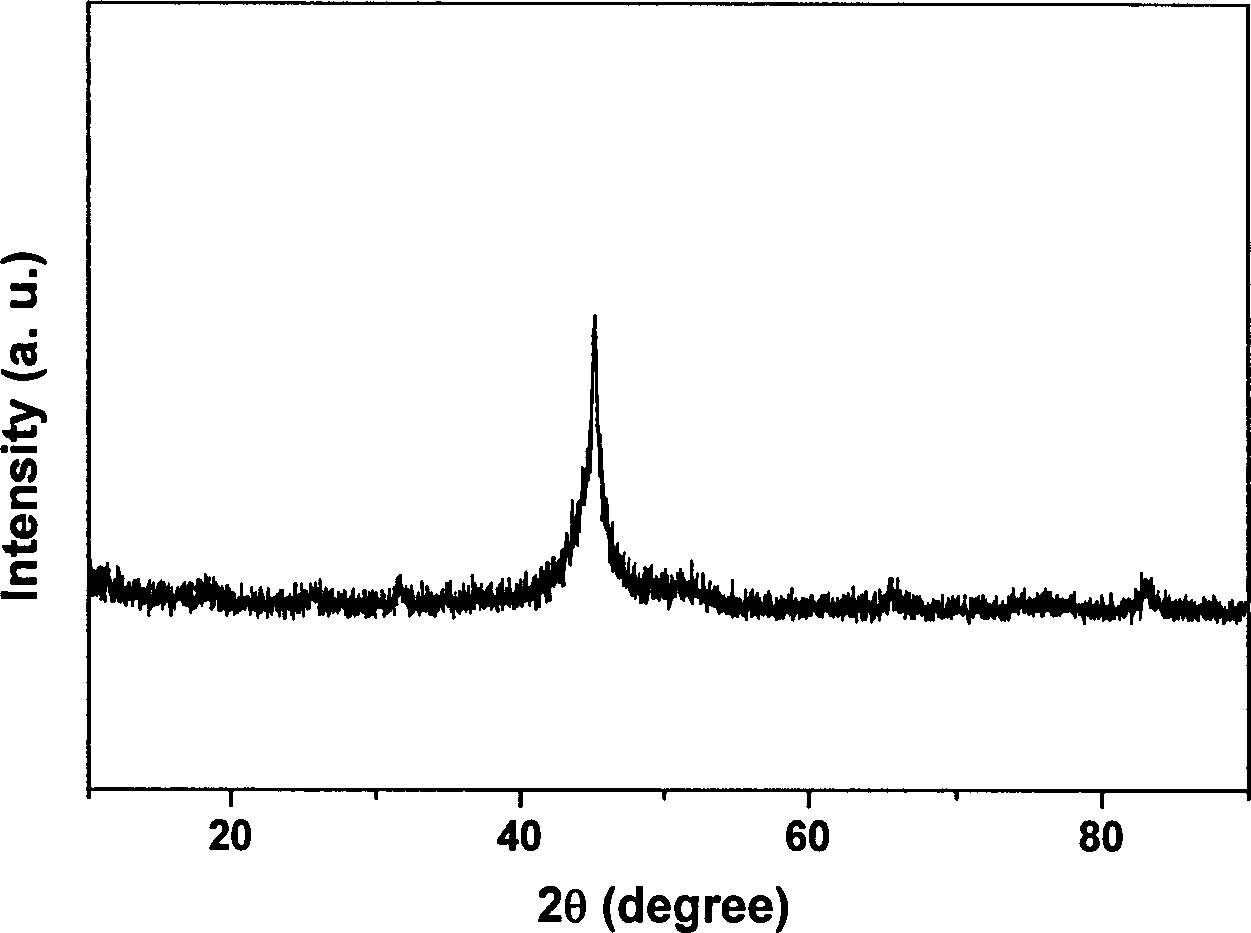

[0018] The present invention is further described below by specific examples. Embodiment 1: Preparation of skeleton nickel-aluminum-chromium-iron amorphous catalyst

[0019] Alloy Formula Pure Nickel 900g

[0020] Pure Aluminum 800g

[0021] Pure Iron 100g

[0022] Pure Chromium 200g

[0023] Alloy powder preparation: Put nickel, aluminum, chromium, and iron into ultrasonic gas atomization equipment and heating furnace for heating, use nitrogen as protective gas, melt injection temperature at 1400±20°C, and roll speed at 800 rpm. The flake alloy obtained is ground to obtain 100-200 mesh particles.

[0024] Catalyst activation: Add the alloy obtained above into 20% sodium hydroxide solution, raise the temperature to 90°C, and 2 Stir for 2 hours under a protective atmosphere, wash with deionized water until neutral after cooling, and remove water in the catalyst with absolute ethanol. Some characterization results of the catalysts are shown in...

Embodiment 2

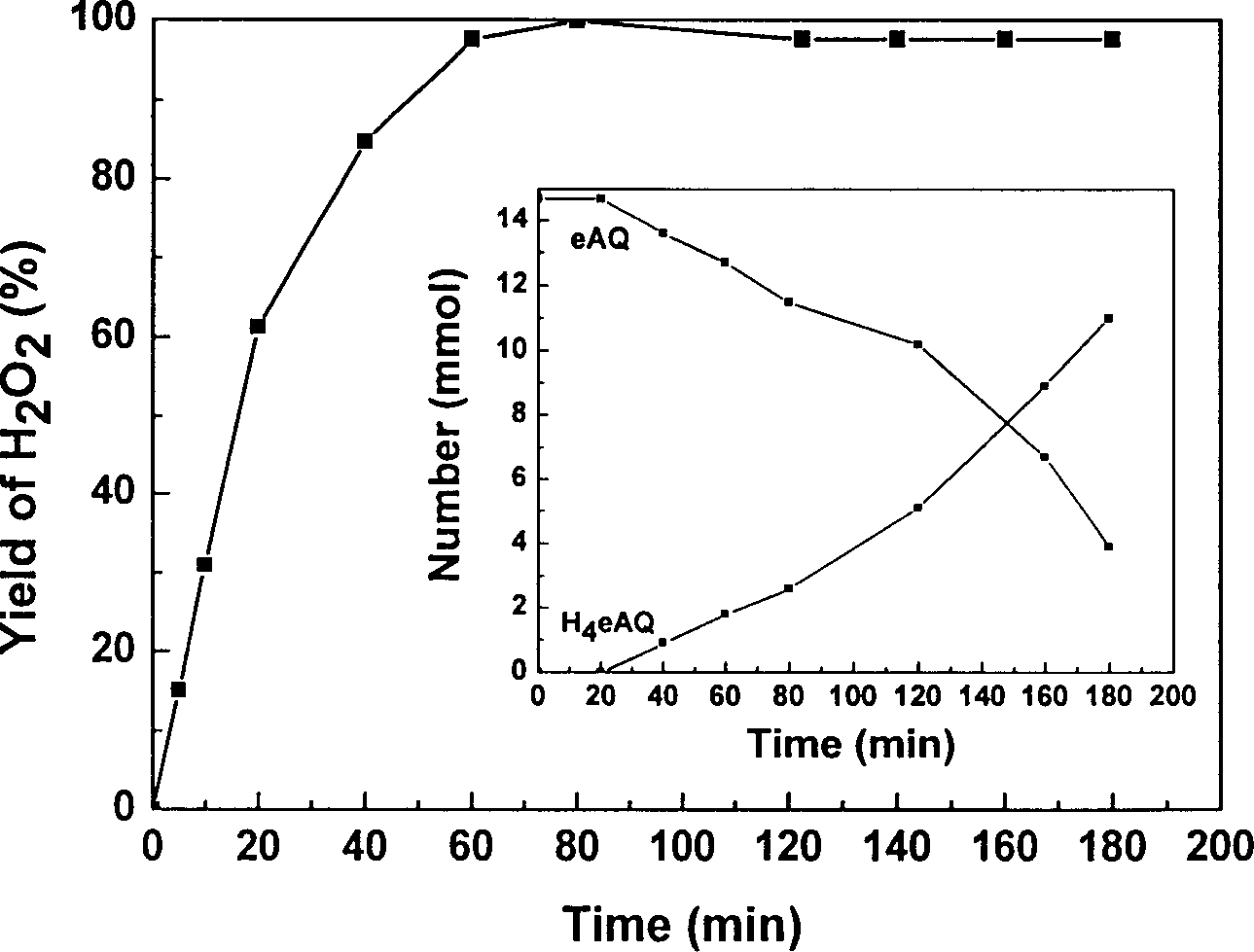

[0029] Anthraquinone hydrogenation: Dissolve 3.5g of anthraquinone in 70mL of a solvent composed of heavy aromatic hydrocarbons and trioctyl phosphate in a volume ratio of 7:3, and put them into the reactor together with 0.5g of catalyst, and fill with hydrogen The pressure is up to 3 atm, the reaction temperature is controlled at 50±2° C., and the stirring rate is 1000 rpm. See the results figure 2 : The yield of hydrogen peroxide can be close to 100%, far exceeding the 70% level of conventional framework nickel. Embodiment 2: Preparation of skeleton nickel aluminum molybdenum amorphous catalyst

[0030] Put an appropriate amount of pure nickel, pure molybdenum and pure aluminum into the ultrasonic gas atomization equipment and heating furnace for heating, use nitrogen as the protective gas, the melting injection temperature is 1400±20°C, and the roller speed is 800 rpm. Flake alloys with different molybdenum contents are obtained, and the particles of 100-200 meshes are o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com