Treatment method for continuous regeneration of hydrogen peroxide working solution produced by anthraquinone process

A technology of hydrogen peroxide and treatment methods, applied in chemical instruments and methods, peroxide/peroxyhydrate/peroxyacid/superoxide/ozonide, inorganic chemistry, etc., can solve the problem of high consumption of raw materials, waste water Large quantity, high labor intensity and other problems, to achieve the effect of low raw material consumption, large processing capacity, and low labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

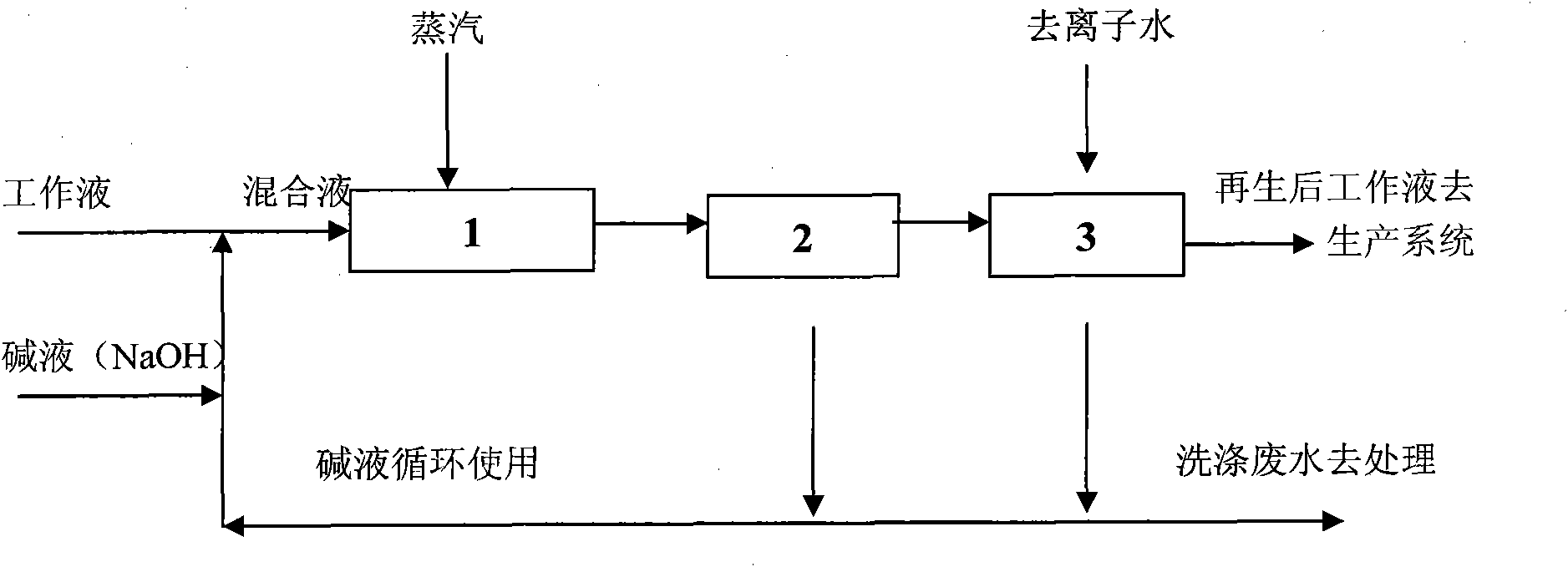

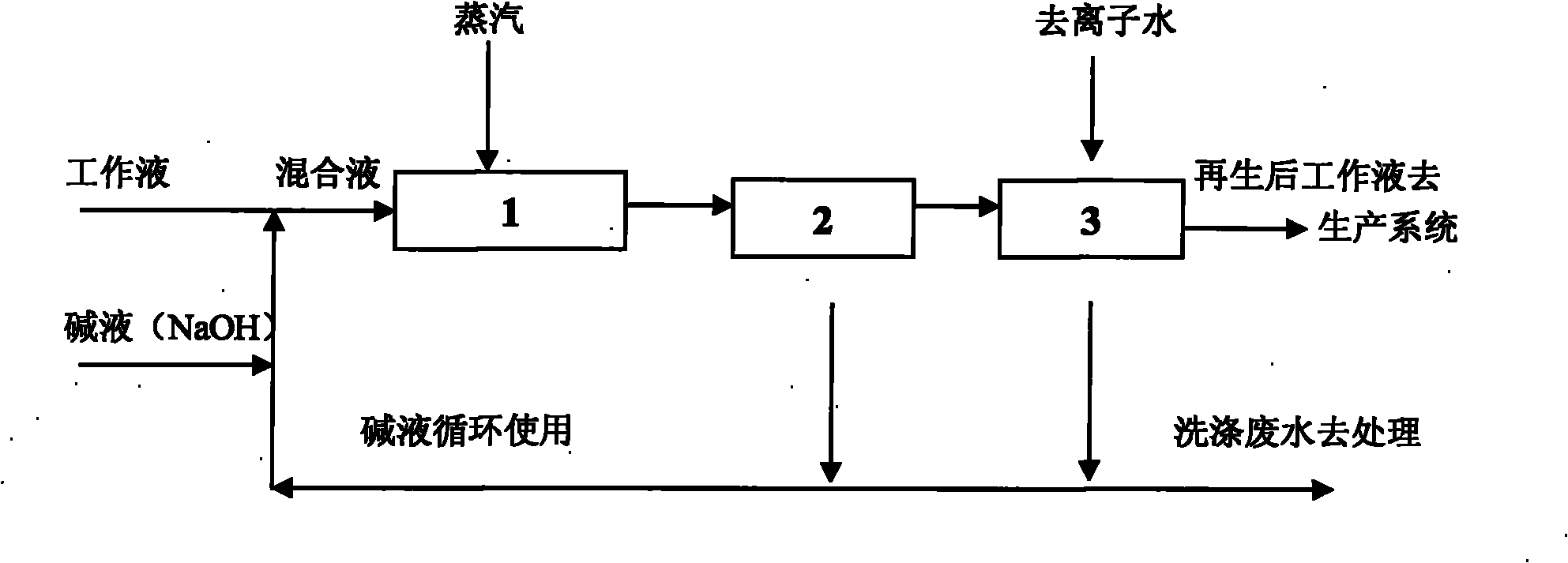

Method used

Image

Examples

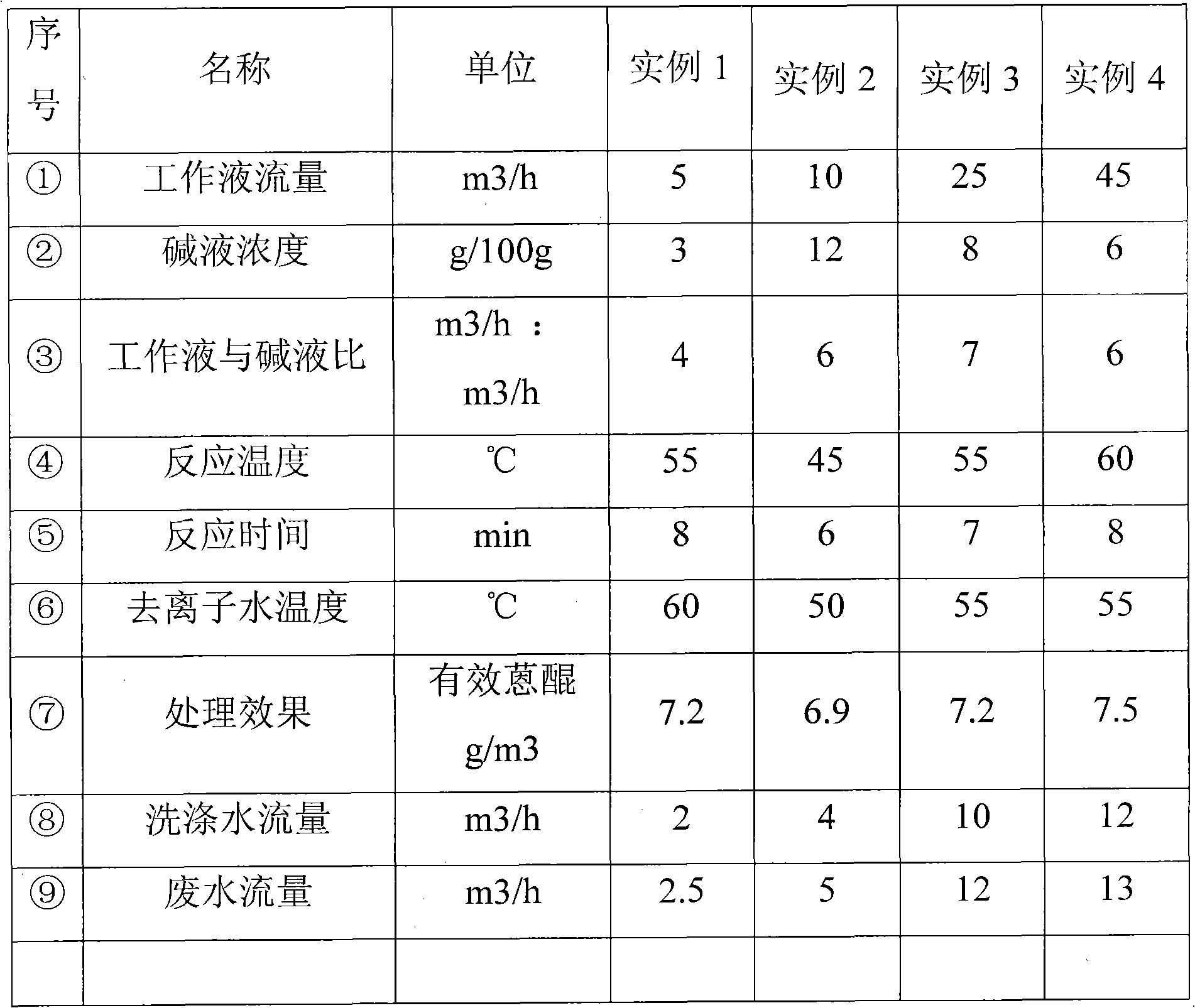

Embodiment 1

[0019] (1) Mix the working solution and the sodium hydroxide solution with a mass content of 15% according to the mass ratio of 5:1;

[0020] (2) The mixed solution of the working fluid and the lye enters the tubular reactor 1 for reaction, and the tubular reactor 1 is heated with steam, and the reaction temperature is controlled at 50-60° C.; the reaction time is 10 minutes;

[0021] (3) The mixed solution after the reaction is separated by the separator 2 to go out the working fluid; the lye separated by the separator 2 enters the above-mentioned step (1) to replace part of the lye for recycling, and the excess lye is used as waste water to process.

[0022] (4) The separated working fluid enters the water washing tower 3 and is washed by deionized water at 60° C., wherein the deionized water refers to water with a resistivity greater than 1 megohm.

[0023] (5) The working liquid after washing with deionized water enters the production system, and the washing liquid washed...

Embodiment 2

[0025] (1) Mix the working solution and the sodium hydroxide solution with a mass content of 8% according to the mass ratio of 3:1;

[0026] (2) The mixed solution of the working fluid and the lye enters the tubular reactor 1 for reaction, and the tubular reactor 1 is heated with steam, and the reaction temperature is controlled at 30-40° C.; the reaction time is 7 minutes;

[0027] (3) After the reaction, the mixed solution is separated from the working fluid by the separator 2; the lye separated by the separator 2 enters the above-mentioned step (1), and is used to replace part of the lye for recycling, and the excess lye is used as waste water to process.

[0028] (4) The separated working fluid enters the water washing tower 3 and is washed with deionized water at 50° C., wherein the deionized water refers to water with a resistivity greater than 1 megohm.

[0029] (5) The working liquid after washing with deionized water enters the production system, and the washing liqu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com