Catalyst support added with hydrogen, peroxide catalyst produced by anthraquinone method and the producing process

A technology of hydrogenation catalyst and hydrogen peroxide, which is applied in the direction of catalyst activation/preparation, catalyst carrier, chemical instrument and method, etc. It can solve the problem that the catalyst activity has not been greatly improved, and achieve high catalyst activity and good stability , good diffusion and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

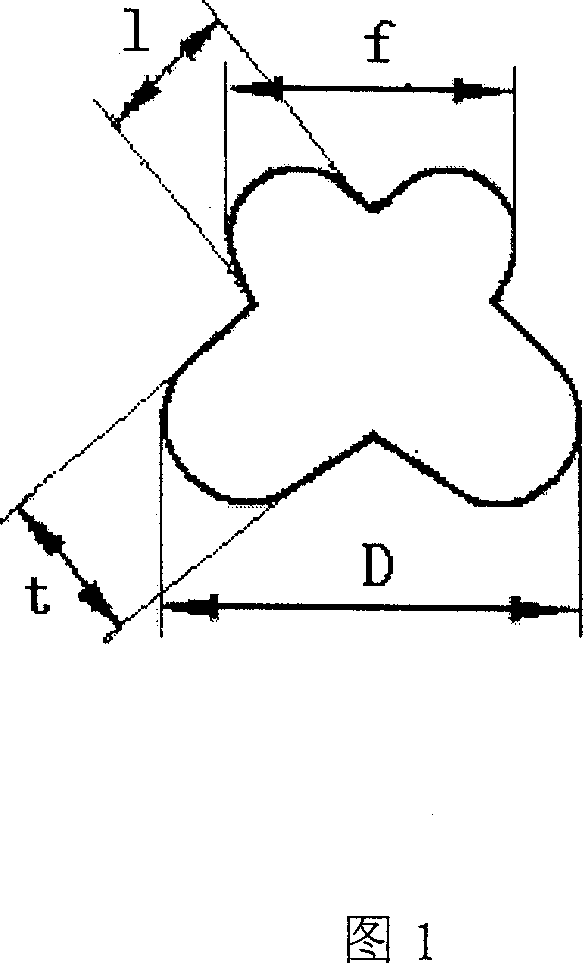

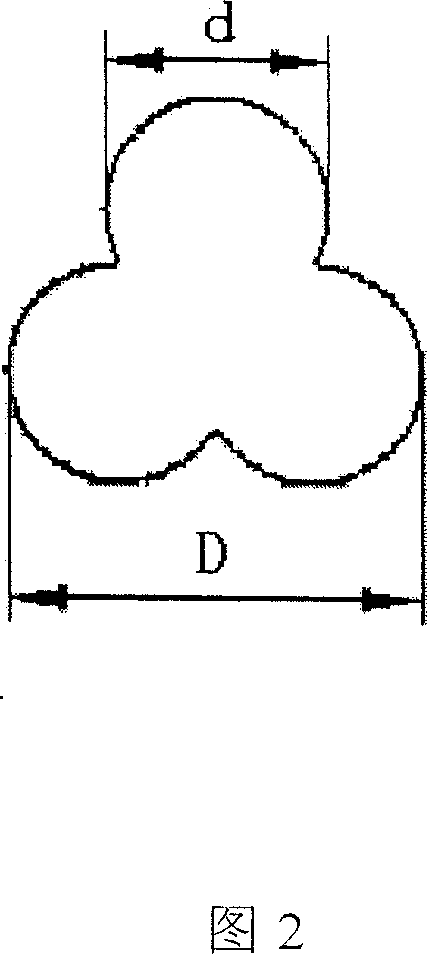

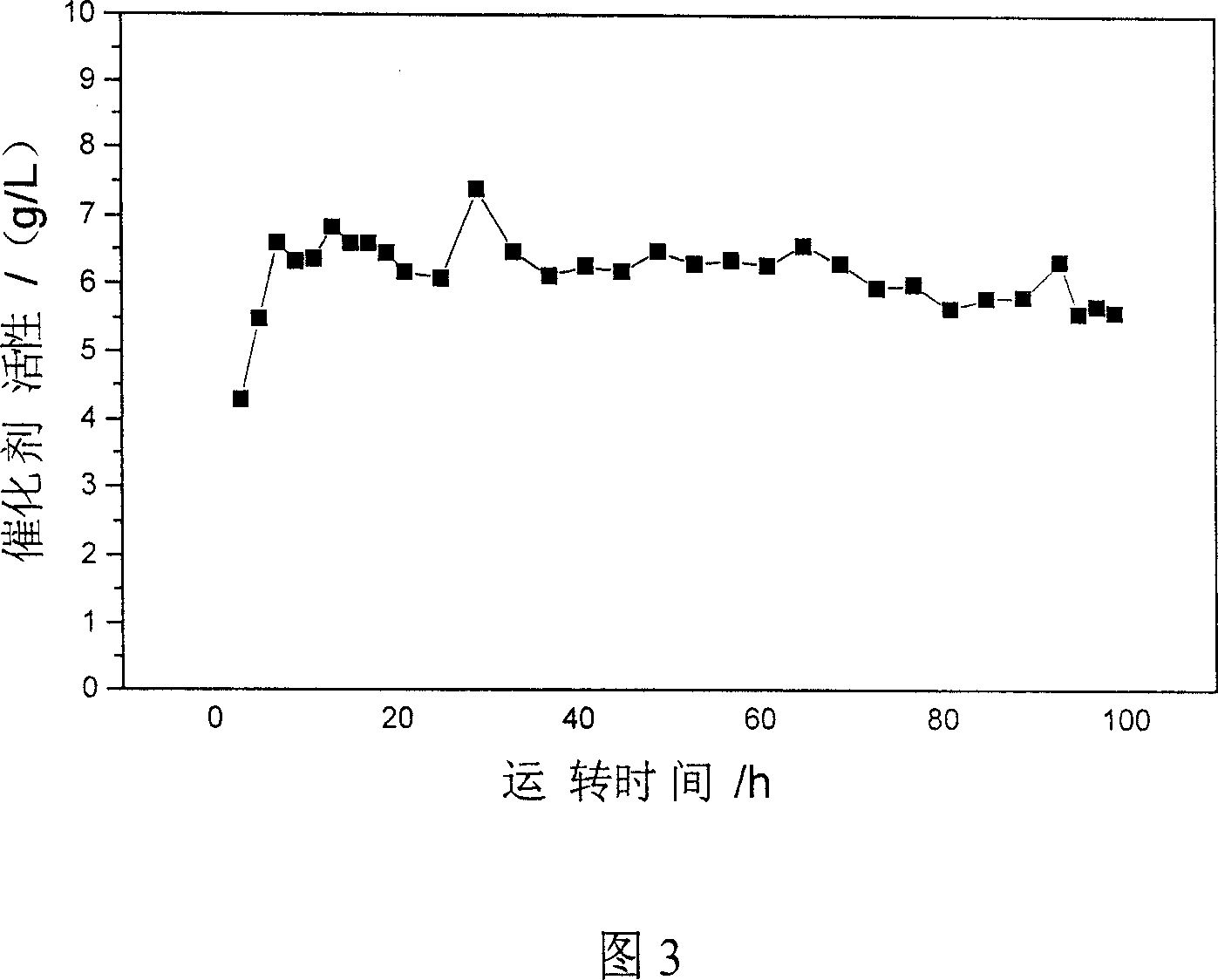

[0039] Dry rubber powder (produced by Sinopec Catalyst Changling Branch Company, BET specific surface area is 335m 2 / g, the pore volume is 1.13cm 3 / g) 50kg, 1kg of safflower powder, 60L of nitric acid solution with a concentration of 2% were kneaded evenly, and extruded a butterfly strip with a maximum diameter D of 1.4mm through an extrusion machine. The cross-sectional shape of the butterfly strip is shown in Figure 1. The specific size parameters are f=1.1mm, t=0.6mm, 1=0.55mm, d=0.75mm. After drying in an oven at 120°C for 4 hours and calcining at 950°C for 4 hours, the obtained carrier is δ-Al 2 o 3 Mainly crystal form, BET specific surface area is 138m 2 / g, the pore volume is 0.66cm 3 / g, bulk ratio is 0.54g / mL, most probable pore size is 14.3nm, 89% pore size distribution>10nm, less than 1% pore size distribution<6nm.

[0040] Measure the above-mentioned carrier of 10mL, and the impregnating solution is obtained by dissolving palladium with hydrochloric acid to ...

Embodiment 2

[0043] Control the pH of the chloropalladium acid solution to 1, impregnate the carrier at room temperature for 20 h, and prepare the carrier and catalyst according to the method in Example 1. The prepared catalyst tends to be homogeneous. The hydrogenation efficiency of the catalyst is 4.31gH 2 o 2 / L.

Embodiment 3

[0045] The pH of the chloropalladium acid solution was controlled to be 5, and the carrier and catalyst were prepared according to the method in Example 1. Precipitation occurs during the impregnation of the chloropalladic acid solution. The hydrogenation efficiency of the catalyst is 4.83gH 2 o 2 / L.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hydrogenation efficiency | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com