Stredford process peroxyl production work liquid post treatment method

A technology for hydrogen peroxide and hydrogen peroxide extraction, applied in chemical instruments and methods, peroxide/peroxyhydrate/peroxyacid/superoxide/ozonide, inorganic chemistry, etc., can solve the problem of reducing active oxidation Problems such as the service life of the aluminum regeneration bed, loss of regeneration degradation products and dissolved degradation products, incomplete separation of lye and working fluid, etc., to achieve remarkable regeneration effect, stable strength and activity, and good working conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

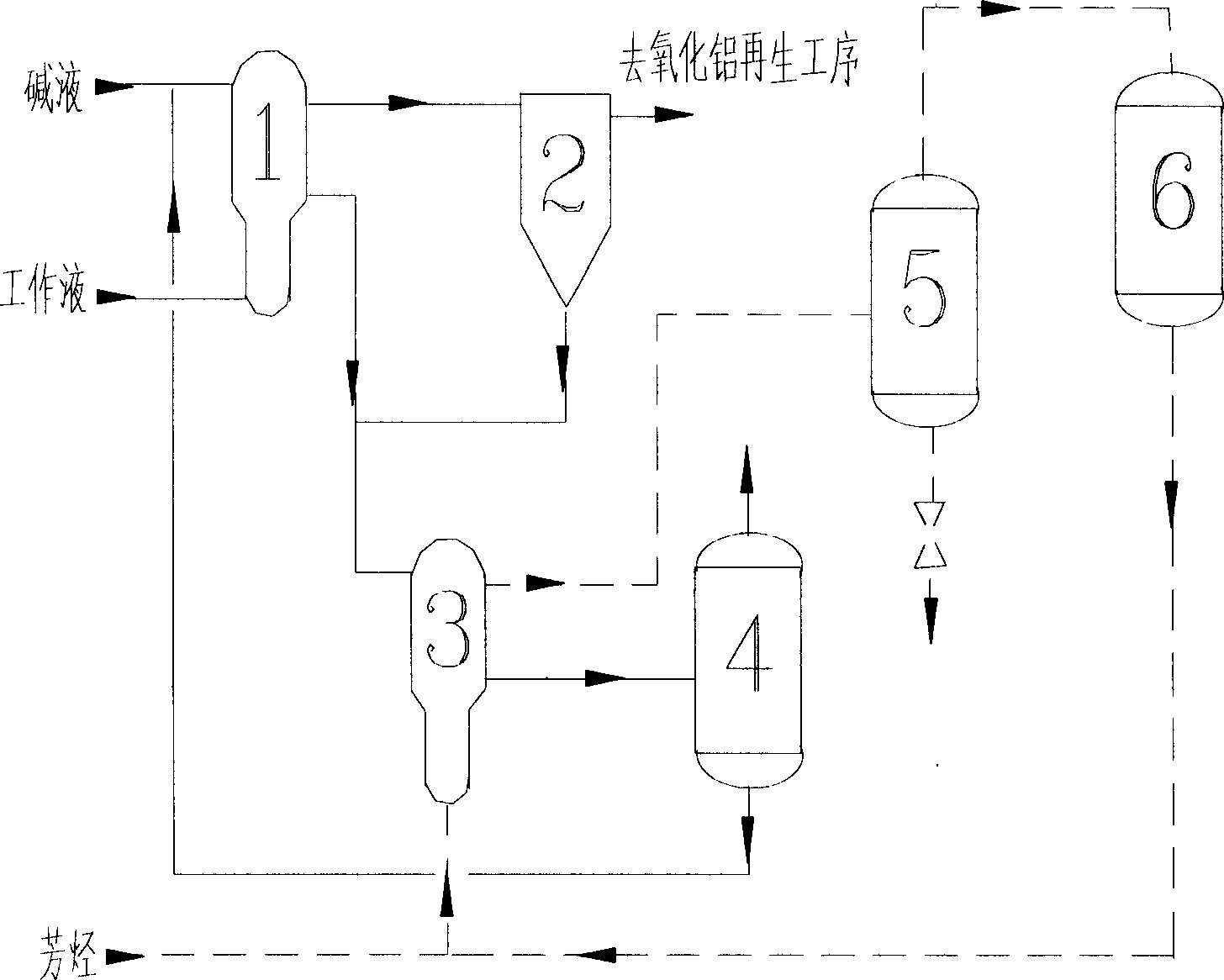

[0011] Embodiment 1: (see figure 1 ) 40% (wt%) concentration, the sodium nitrate lye of PH=11.3 enters from alkali tower 1 top, and flow rate is 9L / h. The working liquid enters from the bottom of the alkali tower 1, and the working liquid contains 10% to 13% (wt%) 2-ethylanthraquinone and a mixture of 5, 6, 7, 8-tetrahydro 2-ethylanthraquinone, and the solvent is 75 % (v%) aromatics and 25% trioctyl phosphate, the moisture content of the working fluid is 0.25% to 0.52%, the content of degradation products is 4.8% to 5.5%, and the flow rate is 150L / h. The treatment temperature in the alkali tower is 50°C, and the pressure is normal pressure. The diluted lye flows out from the bottom of the tower, and the flow rate is 12L / h. According to the above operating conditions, after the working fluid is treated by the alkali tower, the moisture content in the working fluid is 0.1-0.15%, the degradation product content is 1.5-2.2%, and the sodium ion content of the crude hydrogen perox...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com