Novel cross-linked polyurethane ballast adhesive for rail transportation

A technology of rail transit and urethane, applied in polyurea/polyurethane adhesives, tracks, roads, etc., can solve problems such as driving safety hazards, affecting the service life of rails, and rail impacts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Component A: 10 parts of MDI;

[0047] Component B: 0.2 parts of DMTDA and 1 part of cyclopentadiene polymer.

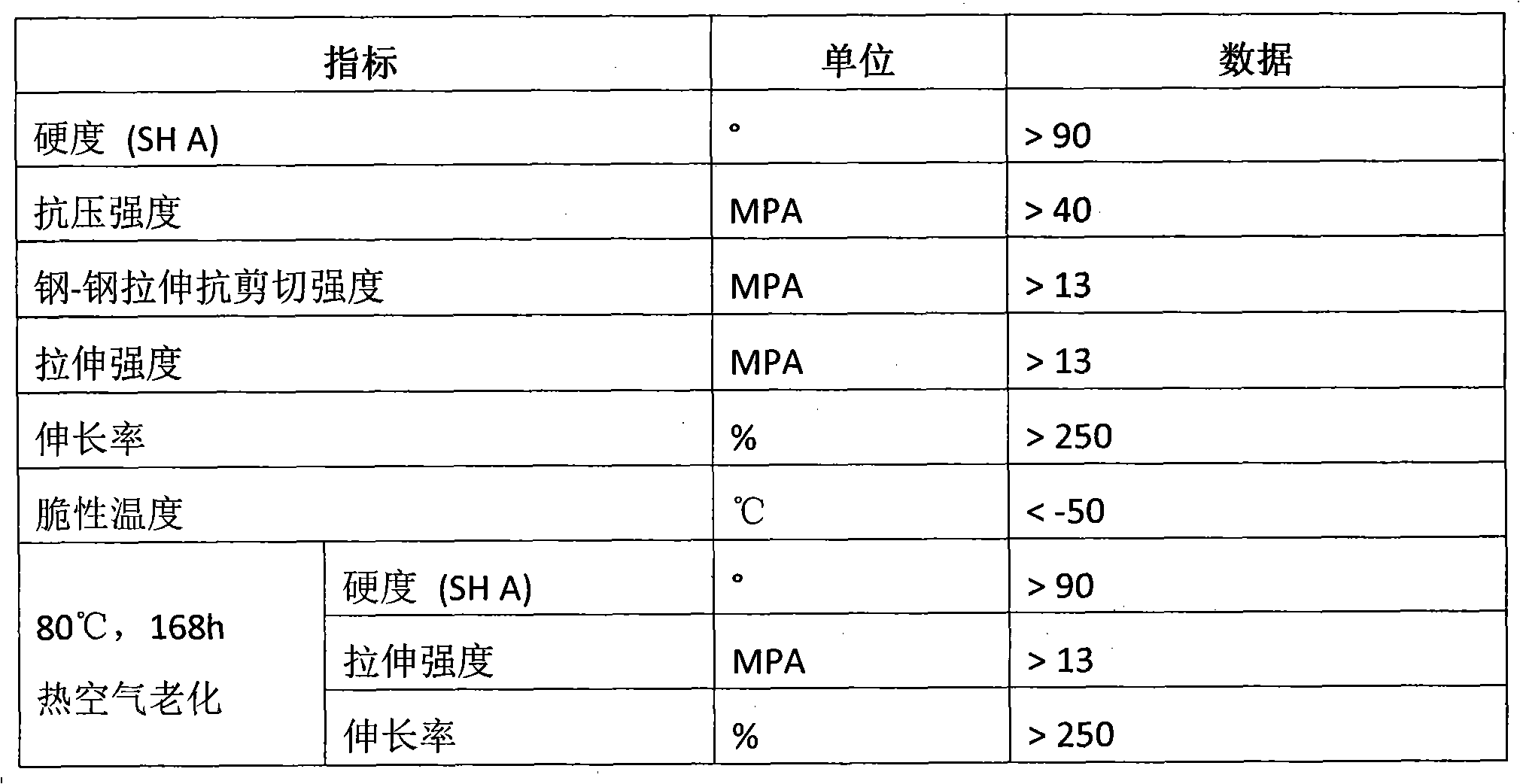

[0048] A and B components are mixed to make a prepolymer with NCO%=14%, which can achieve the following properties.

[0049]

Embodiment 2

[0051] Component A: a mixture of 2,4'-TDI and 2,6'-TDI in a weight ratio of 4:1, 10 parts;

[0052] Component B: a mixture of trimethylolpropane and styrene copolymer resin according to 1:1, 8 parts;

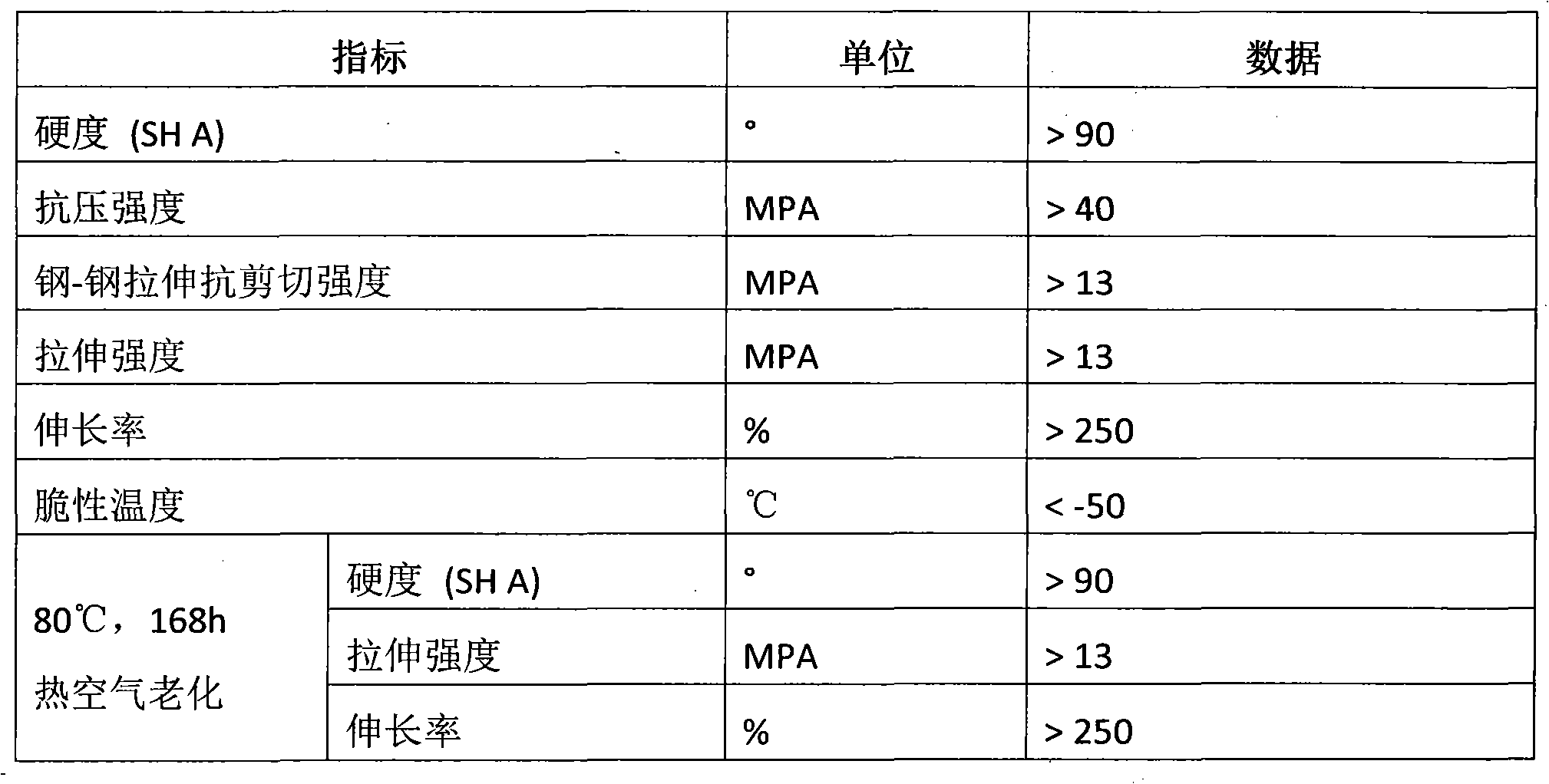

[0053] A and B components are mixed to make a prepolymer with NCO%=12%, which can achieve the following properties

[0054]

Embodiment 3

[0056] Component A: TDI 5 parts;

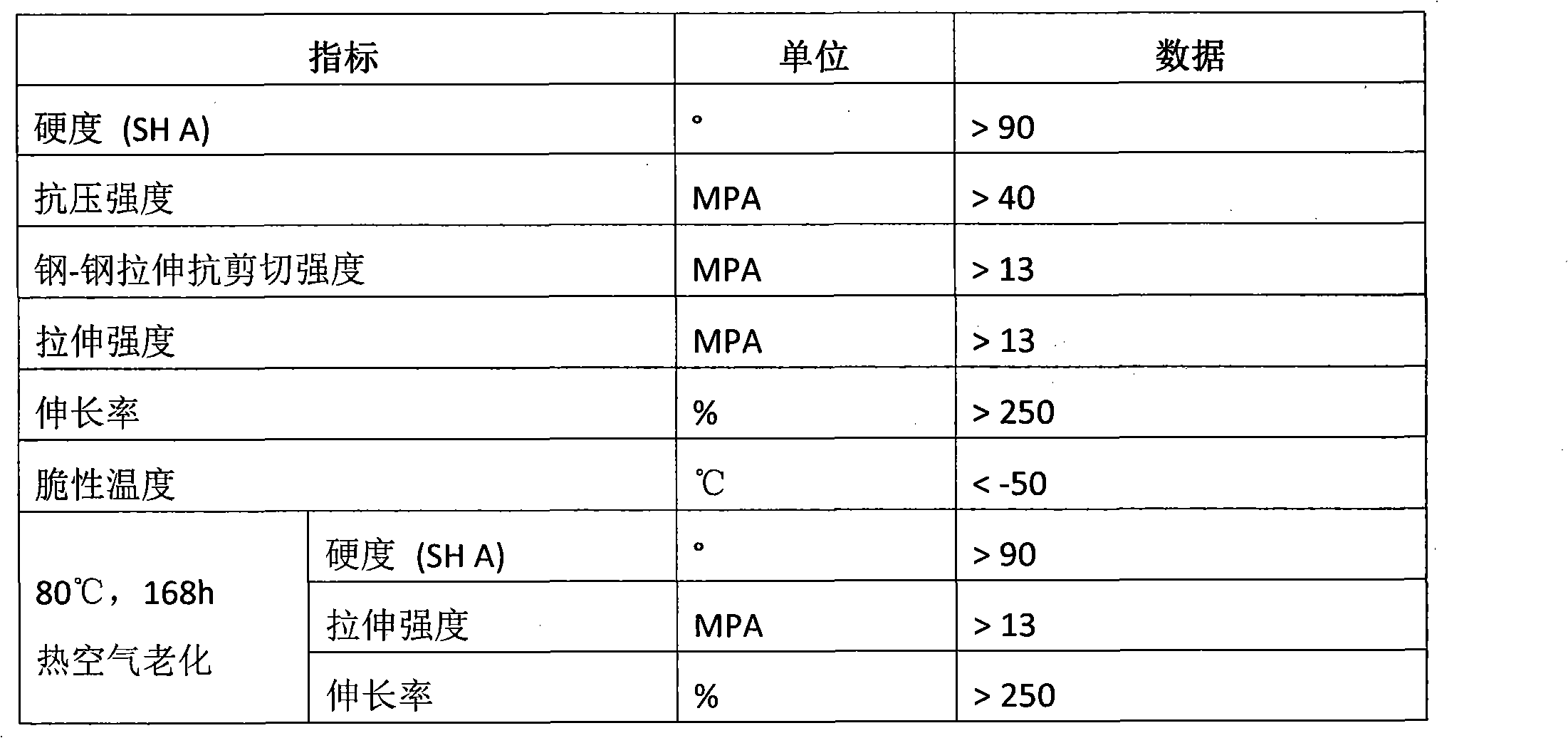

[0057] Component B: a mixture of polycarbonate and phthalic anhydride in a weight ratio of 0.1:1, 30 parts; components A and B are mixed to make a prepolymer with NCO%=12%, which can achieve the following properties

[0058]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com