Surface recombination processing method for rare earth-magnesium-nickel based AB3 type hydrogen storage alloy

A technology of hydrogen storage alloy and surface compounding, which is applied in metal material coating technology, liquid chemical plating, coating, etc., can solve the problems of cumbersome processing steps, wasteful treatment of waste liquid volume, pulverization, etc., and achieve cycle stability and dynamic performance improvement, simple and convenient operation, and the effect of reducing environmental pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Process: According to AB 3 Type hydrogen storage alloy La 0.88 Mg 0.12 Ni 2.95 mn 0.10 co 0.55 Al 0.10 Weigh a certain amount of La, Mg, Ni, Mn, Co, Al (purity ≥ 99.5%) metal, under the protection of argon, use the method of induction melting in the medium frequency induction furnace to melt the above metal and pour it into the cooling In a copper mold cooled by water circulation, an alloy ingot is obtained. Then the alloy ingot is annealed at a high temperature of 1173K for 6 hours, and finally the hydrogen storage alloy is ground and pulverized at room temperature, and passed through a 200-400 mesh sieve to obtain a hydrogen storage alloy powder. Weigh 2g of the hydrogen storage alloy powder sample and put it into the prepared 60ml chemical etching treatment solution. The composition of the chemical etching solution is: 0.015mol / L HF and 0.1mol / L KF (treatment agent), 0.15mol / L NaAc and 0.015mol / L HAc (buffer solution), 0.05mol / LNaH 2 PO 2 ·H 2 O (reducing a...

Embodiment 2~5

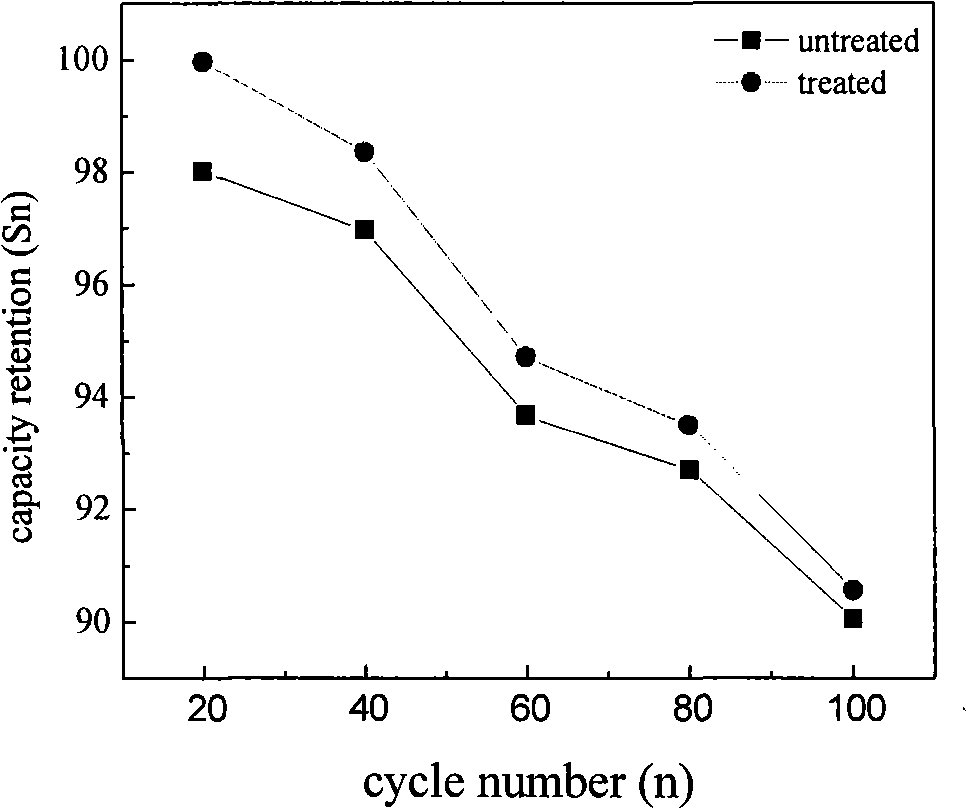

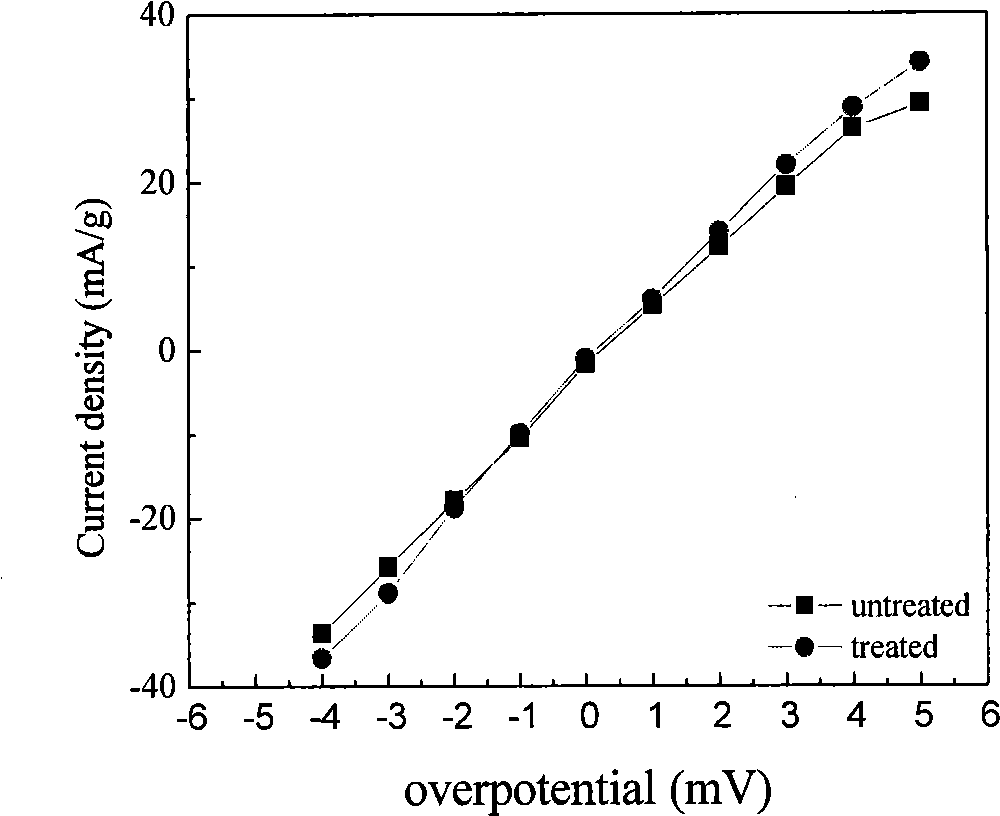

[0034] According to the process parameters of hydrogen storage alloy smelting and annealing in embodiment 1, smelting rare earth-magnesium-nickel based hydrogen storage alloy La 0.72 Mg 0.28 Ni 2.15 mn 0.14 co 0.45 Al 0.11 , and according to the experimental parameters listed in Table 2, the surface composite treatment was performed on the prepared hydrogen storage alloy. The electrochemical performance and kinetic performance test results of the hydrogen storage alloy before and after treatment are shown in Figure 6 ~ Figure 9 .

[0035] Table 2 Composition (mol / L) and treatment condition parameters of the surface composite treatment solution used in Examples 2 to 5

[0036]

[0037] Note: A stands for hydrogen storage alloy La 0.72 Mg 0.28 Ni 2.15 mn 0.14 co 0.45 Al 0.11

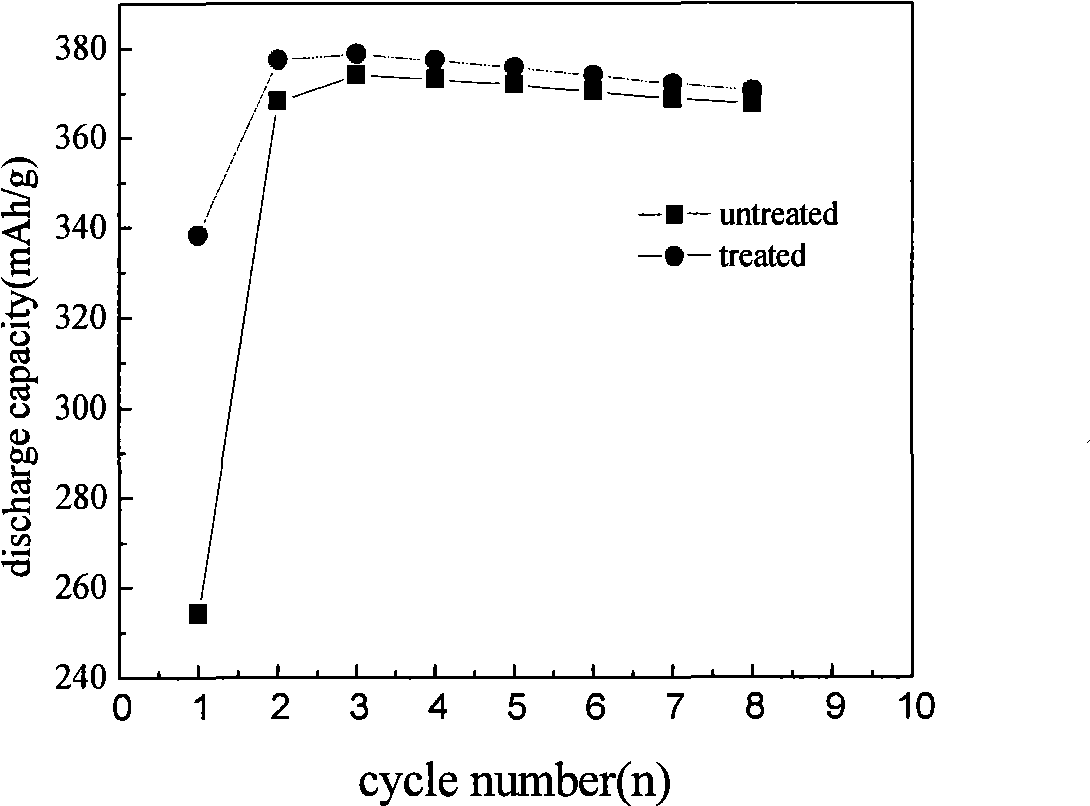

[0038] figure 1 It is the initial activation curve graph of the hydrogen storage alloy powder treated in Example 1 and the untreated hydrogen storage alloy powder. It can be seen that th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com