Method for preparing germanium cathode material on nickel nanoneedle conical array

A negative electrode material and nano-needle technology, which is applied in the field of preparing germanium negative electrode materials on nickel nano-needle cone arrays, to achieve the effects of uniform germanium film, good bonding force, and large base area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

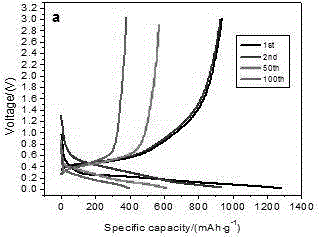

Examples

Embodiment 1

[0035] (1) Treatment of negative electrode substrate

[0036] Before using the directional electrocrystallization method to electroplate a layer of nickel nano needle cone array on the surface of the nickel foil, the nickel foil is firstly subjected to texturing treatment. Immerse for 5 minutes, wash with deionized water, and dry;

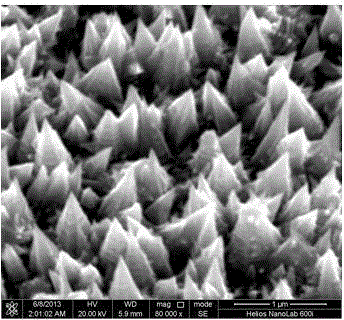

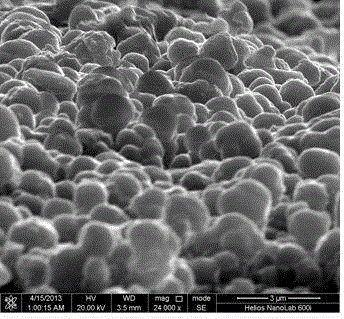

[0037] (2) Preparation of nickel nano needle cone arrays by directional electrocrystallization method

[0038] Nickel nano-needle cone arrays were prepared by directional electrocrystallization without a template; the raw materials used were all analytically pure chemical reagents, and pure deionized water was used to prepare the solution, and the composition of the control solution was: nickel chloride 1.0mol / L , boric acid 0.5mol / L, ammonium chloride 4.0mol / L, and use 10% ammonia water and 10% hydrochloric acid to adjust the pH of the solution to 4.0, the electrodeposition temperature is 50~60℃, and the time is 4min; after completion Rinse with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com