High-radial and high-tap density nickel cobalt lithium aluminate precursor and preparation method thereof

A nickel-cobalt lithium aluminate and precursor technology, applied in electrical components, battery electrodes, circuits, etc., can solve the problems of low tap density, poor electrochemical performance of sintered products, uneven distribution of aluminum elements, etc., and achieve high tap density , high sphericity, the effect of compact internal structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] A preparation method of a highly radial and highly compacted nickel-cobalt-lithium aluminate precursor, comprising the following steps:

[0031] (1) Configuration of the reaction solution: dissolving the nickel salt and the cobalt salt into a mixed salt solution with a concentration of 1 to 3 mol / L, and preparing the aluminum salt into an aluminum salt solution with a concentration of 0.05 to 0.5 mol / L, (preparing the aluminum salt During the solution, an appropriate amount of sodium hydroxide can be selectively added as a co-solvent); the alkali is dissolved into an alkali solution with a concentration of 4-10 mol / L; and an aqueous ammonia solution of 5-13 mol / L is used as a complexing agent.

[0032] Wherein the nickel salt is one of nickel sulfate, nickel chloride, nickel nitrate and nickel acetate; the cobalt salt is one of cobalt sulfate, cobalt chloride, cobalt nitrate and cobalt acetate; the aluminum salt is Sodium metaaluminate; The alkali is sodium hydroxide. ...

Embodiment 1

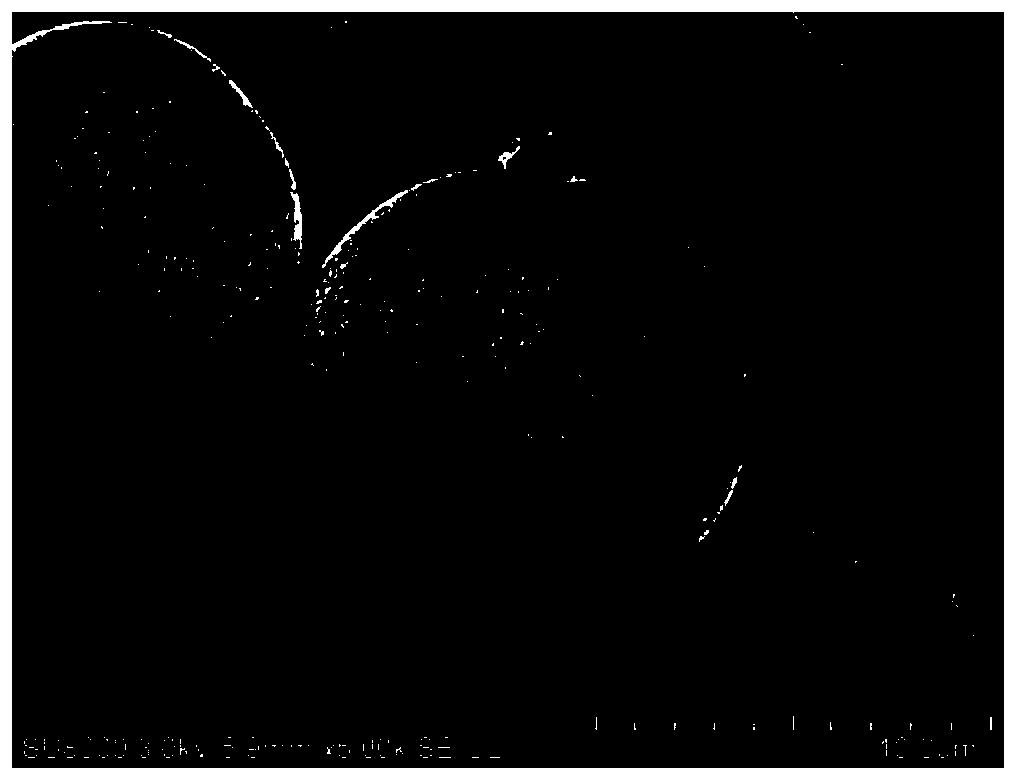

[0043] Figure 1-4 Shown is the high radial, high vibration nickel cobalt lithium aluminate precursor of the present invention, the molecular formula of the nickel cobalt lithium aluminate precursor is Ni 0.82 co 0.15 Al 0.03 (OH) 2 ; The cross-sectional morphology of the nickel-cobalt-lithium-aluminate precursor is radial from the inside to the outside, and the aluminum element in the material is evenly distributed from the inside to the outside. The primary particle of the precursor is flake-shaped, and the secondary particle is highly spherical. The tap density of the nickel cobalt lithium aluminate precursor is 2.0g / cm 3 , specific surface area 15m 2 / g. The preparation method of the nickel-cobalt-lithium-aluminate precursor of the foregoing embodiment comprises the following steps:

[0044] (1) Configuration of the reaction solution: Dissolve nickel sulfate and cobalt sulfate into a mixed salt solution with a concentration of 2mol / L, prepare sodium metaaluminate in...

Embodiment 2

[0050] The molecular formula of nickel cobalt lithium aluminate precursor is Ni 0.88 co 0.09 Al 0.03 (OH) 2 ; The cross-sectional morphology of the nickel-cobalt-lithium-aluminate precursor is radial from the inside to the outside, and the aluminum element in the material is evenly distributed from the inside to the outside. The primary particle of the precursor is flake-shaped, and the secondary particle is highly spherical. The tap density of the nickel cobalt lithium aluminate precursor is 1.9g / cm 3 , specific surface area 10m 2 / g. The preparation method of the nickel-cobalt-lithium-aluminate precursor of the foregoing embodiment comprises the following steps:

[0051] (1) Configuration of the reaction solution: nickel nitrate and cobalt nitrate are dissolved into a mixed salt solution with a concentration of 1mol / L, and sodium metaaluminate is prepared into a sodium metaaluminate solution with a concentration of 0.05mol / L; Dissolve into a sodium hydroxide solution ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com