Battery electrode splice, preparation thereof, and battery prepared by the electrode splice

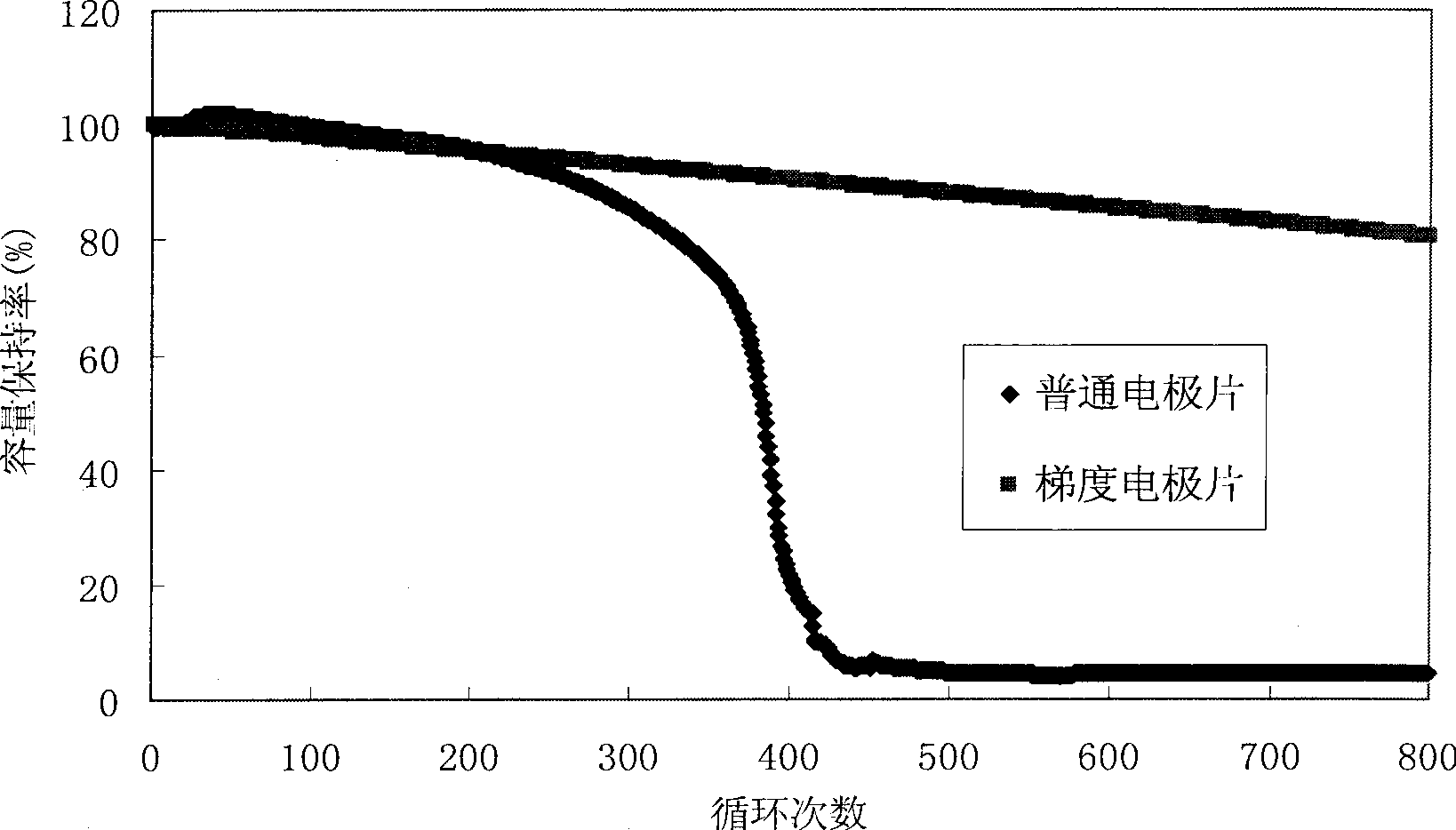

A battery electrode and electrode sheet technology, applied in the direction of electrode manufacturing, secondary batteries, active material electrodes, etc., to achieve the effects of good machinability, excellent toughness, and good cycle stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

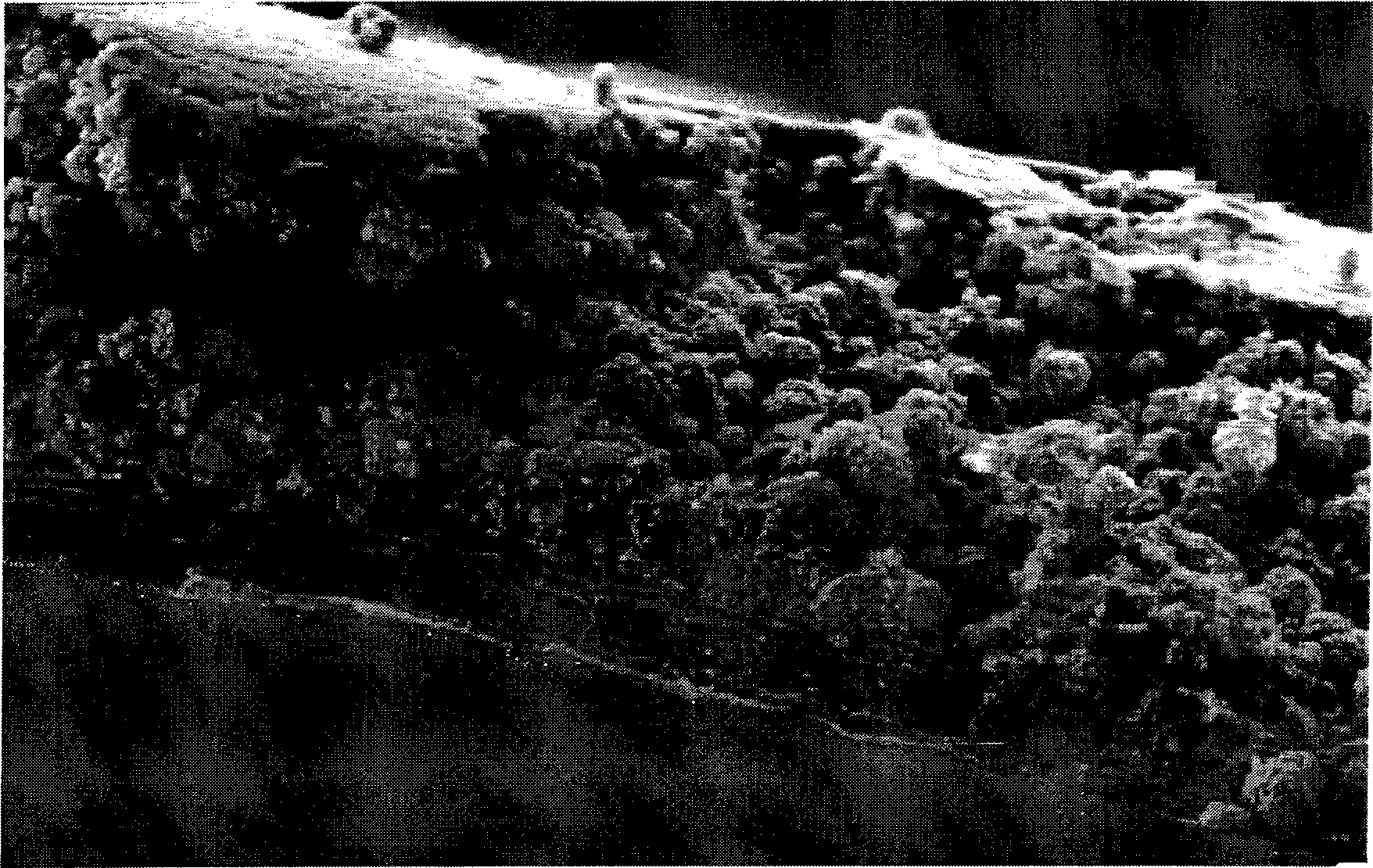

Image

Examples

Embodiment 1

[0045] Taking LiCol / 3Nil / 3Mnl / 3O2 as the research object, the specific preparation method of this battery electrode sheet includes the following steps:

[0046] The first step: 200g LiCo 1 / 3 Ni 1 / 3 mn 1 / 3 o 2 With 20g acetylene black conductive agent, evenly dispersed in 300g N-methylpyrrolidone (NMP) solvent to prepare LiCo 1 / 3 Ni 1 / 3 mn 1 / 3 o 2 - conductive agent mixture.

[0047] Step 2: Add 20g of polyvinylidene fluoride (PVDF) binder to mix and make slurry, stir at a high speed of 4000 rpm, stir for 10 minutes every time, stop for 10 minutes in the middle, and stir at high speed for no less than 2 hours. The entire slurry was thoroughly mixed and the viscosity of the slurry was 560 centipoise (C.P.S.).

[0048] Step 3: Coat the prepared slurry on a coating machine, let it stand for 1 hour, and then dry it. The dry thickness of the electrode sheet is controlled between 60 μm and 120 μm.

[0049] Step 4: Use a rolling machine to press the prepared electrode sheet t...

Embodiment 2

[0051] Take LiNi 0.8 co 0.15 al 0.05 o 2 As the research object, the specific preparation method of this battery electrode sheet includes the following steps:

[0052] The first step: 200g LiNi 0.8 co 0.15 al 0.05 o 2 With 12g acetylene black conductive agent, uniformly dispersed in 200g N-methylpyrrolidone (NMP) solvent to prepare LiNi0.8 co 0.15 al 0.05 o 2 - conductive agent mixture.

[0053] Step 2: Add 18g polyvinylidene fluoride (PVDF) binder to mix and make slurry, stir at a high speed of 4000 rpm, stir for 10 minutes every time, stop for 10 minutes in the middle, and stir at high speed for no less than 2 hours. The whole slurry is fully mixed evenly, and the viscosity of the slurry is 520C.P.S.

[0054] Step 3: Coat the prepared slurry on a coating machine, let it stand for 1 hour, and then dry it. The dry thickness of the electrode sheet is controlled between 60 μm and 120 μm.

[0055] Step 4: Use a rolling machine to press the prepared electrode sheet to ...

Embodiment 3

[0057] LiCoO 2 As the research object, the specific preparation method of this battery electrode sheet includes the following steps:

[0058] The first step: 200g LiCoO 2 and 15g acetylene black conductive agent, uniformly dispersed in 200g N-methylpyrrolidone (NMP) solvent to prepare LiCoO 2 - conductive agent mixture.

[0059] Step 2: Add 20g of polyvinylidene fluoride (PVDF) binder to mix and make slurry, stir at a high speed of 4000 rpm, stir for 10 minutes every time, stop for 10 minutes in the middle, and stir at high speed for no less than 2 hours. The whole slurry is fully mixed evenly, and the viscosity of the slurry is 480C.P.S.

[0060] Step 3: Coat the prepared slurry on a coating machine, let it stand for 1 hour, and then dry it. The dry thickness of the electrode sheet is controlled between 60 μm and 120 μm.

[0061] Step 4: Use a rolling machine to press the prepared electrode sheet to a porosity of about 35%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com