Preparation method of silicon carbon negative electrode precursor

A technology of precursor and negative electrode, applied in the field of preparation of silicon carbon negative electrode precursor, can solve the problems of poor controllability of composite structure and particle size, poor material capacity, and difficulty in commercial use, so as to ensure the activity of nano-silicon and improve the first effect. and cycle performance, the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

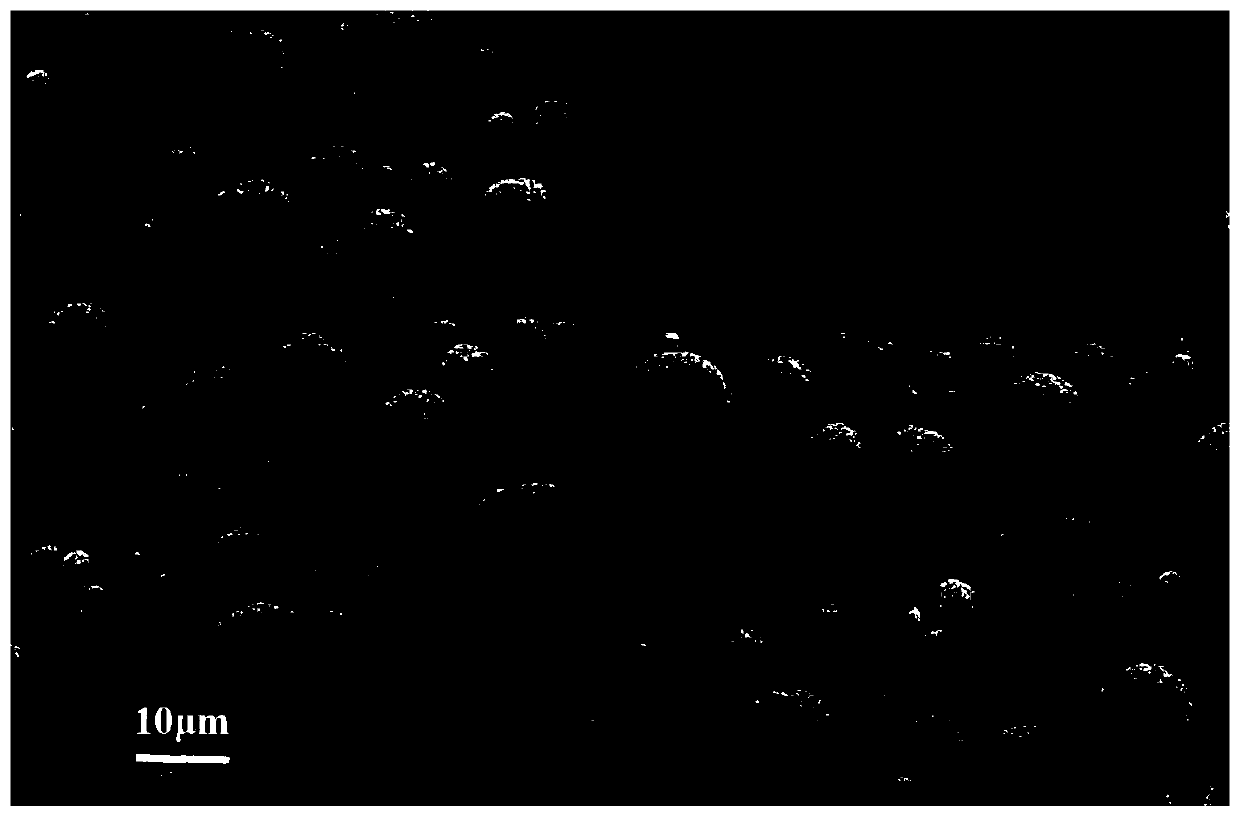

Image

Examples

Embodiment 1

[0040] A method for preparing a silicon-carbon negative electrode precursor of the present invention, comprising the following steps:

[0041] (1) Add nano-silica powder with a particle diameter of D50=120nm and artificial graphite powder with a particle diameter of D50=6 μm in N-methylpyrrolidone (wherein the mass ratio of nano-silicon powder and artificial graphite powder is 20:100, powder The mass ratio to the solvent is 30:100), and then placed in a sand mill for dispersion (the grinding process is sealed and nitrogen gas is introduced for protection), the sanding speed is 1200rpm, and the sanding time is 1h to obtain a uniformly dispersed slurry of nano-silicon A;

[0042] (2) Dissolve stearic acid in N-methylpyrrolidinium in a mass ratio of 40:100, and fully mix and stir it with a mechanical stirrer at a speed of 1500 rpm for 30 minutes to prepare slurry B;

[0043] (3) Graphene is dissolved in N-methylpyrrolidinium in a mass ratio of 2:100, and the mixed solution is ul...

Embodiment 2

[0061] A method for preparing a silicon-carbon negative electrode precursor of the present invention, comprising the following steps:

[0062] (1) Add the nano silicon powder of particle diameter D50=100nm and the mesophase carbon microsphere of particle diameter D50=8 μ m in dehydrated alcohol (the mass ratio of nano silicon powder and mesocarbon microsphere is 25:100, powder The mass ratio to the solvent is 30:100), and the sand mill is used for dispersing (nitrogen protection) grinding, the sand milling speed is 1500rpm, and the sand milling time is 45min, and the slurry A with uniform dispersion of nano-silicon is obtained;

[0063] (2) Dissolve palmitic acid in absolute ethanol at a mass ratio of 50:100, fully mix and stir the mixture with a mechanical stirrer at a rotating speed of 1500 rpm, and stir for 30 minutes to obtain slurry B;

[0064] (3) dissolving the carbon nanotubes in absolute ethanol at a mass ratio of 5:100, and ultrasonically dispersing the mixed solutio...

Embodiment 3

[0068] A method for preparing a silicon-carbon negative electrode precursor of the present invention, comprising the following steps:

[0069] (1) Add the nano silicon powder of particle diameter D50=100nm and the natural graphite micropowder of particle diameter D50=6 μm in acetone (the mass ratio of medium nanometer silicon powder and natural graphite micropowder is 20:100, the mass ratio of powder material and solvent 25:100), disperse with a planetary ball mill (nitrogen protection during the sand milling process), the ball milling speed is 1800rpm, the ball milling time is 45min, and the slurry A with uniform dispersion of nano-silicon is obtained;

[0070] (2) Dissolve sebacic acid in acetone at a mass ratio of 40:100, fully mix and stir with a mechanical stirrer, rotate at 1500 rpm, and take 30 minutes to prepare slurry B;

[0071] (3) Graphene is dissolved in acetone by the mass ratio of 2:100, carries out ultrasonic dispersion with ultrasonic disperser, frequency 10kh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com