Patents

Literature

52results about How to "Save gas consumption" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

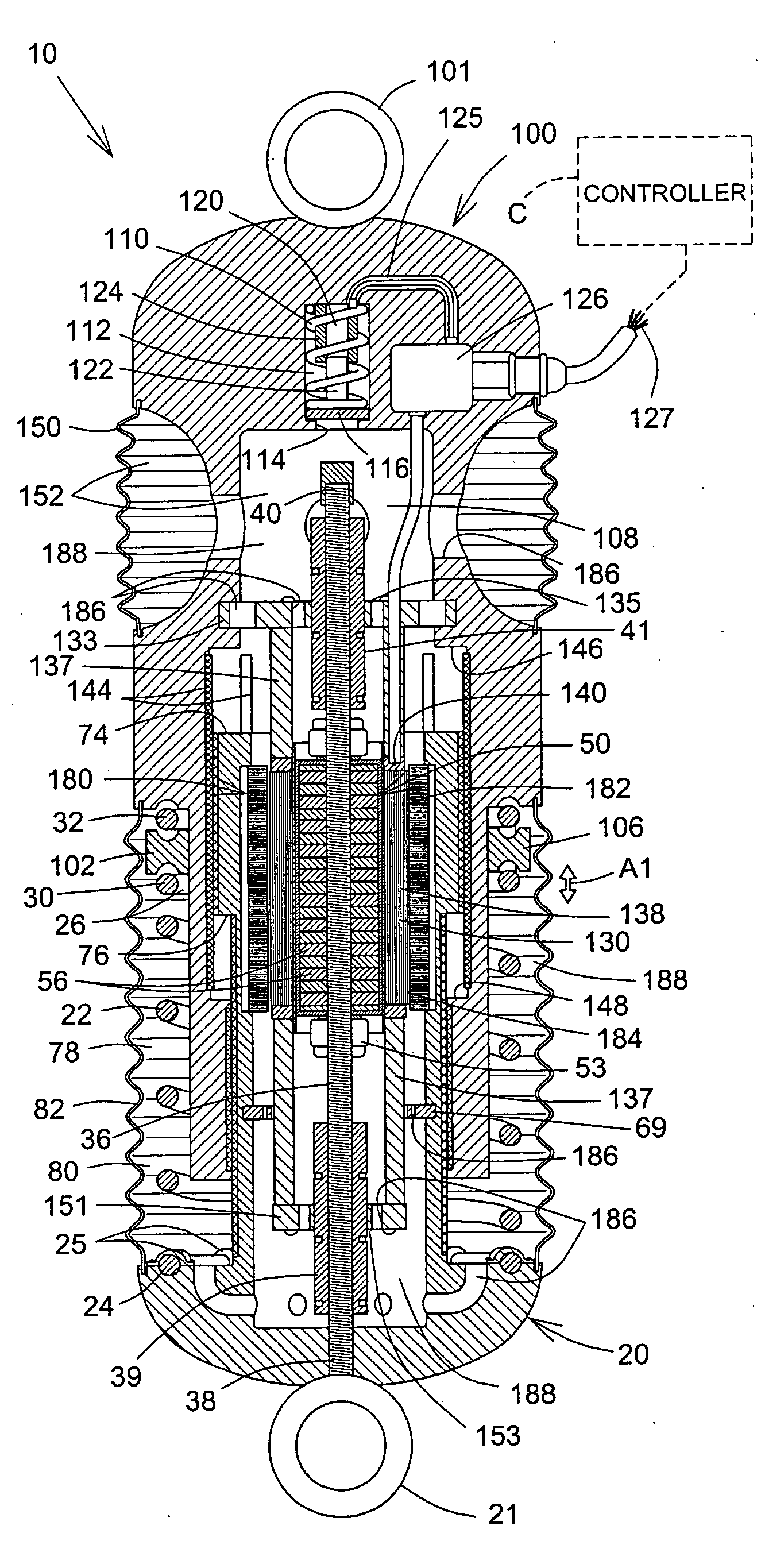

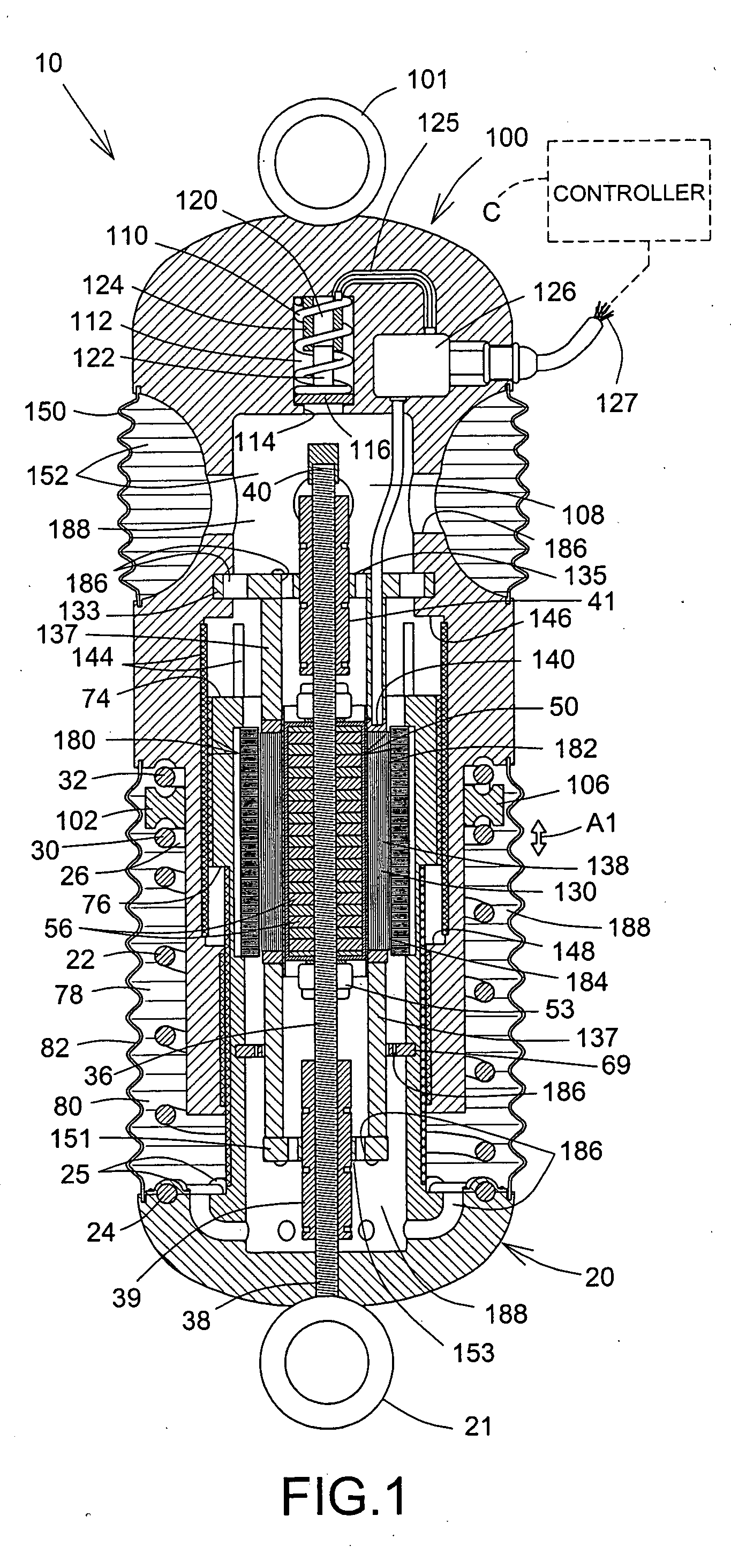

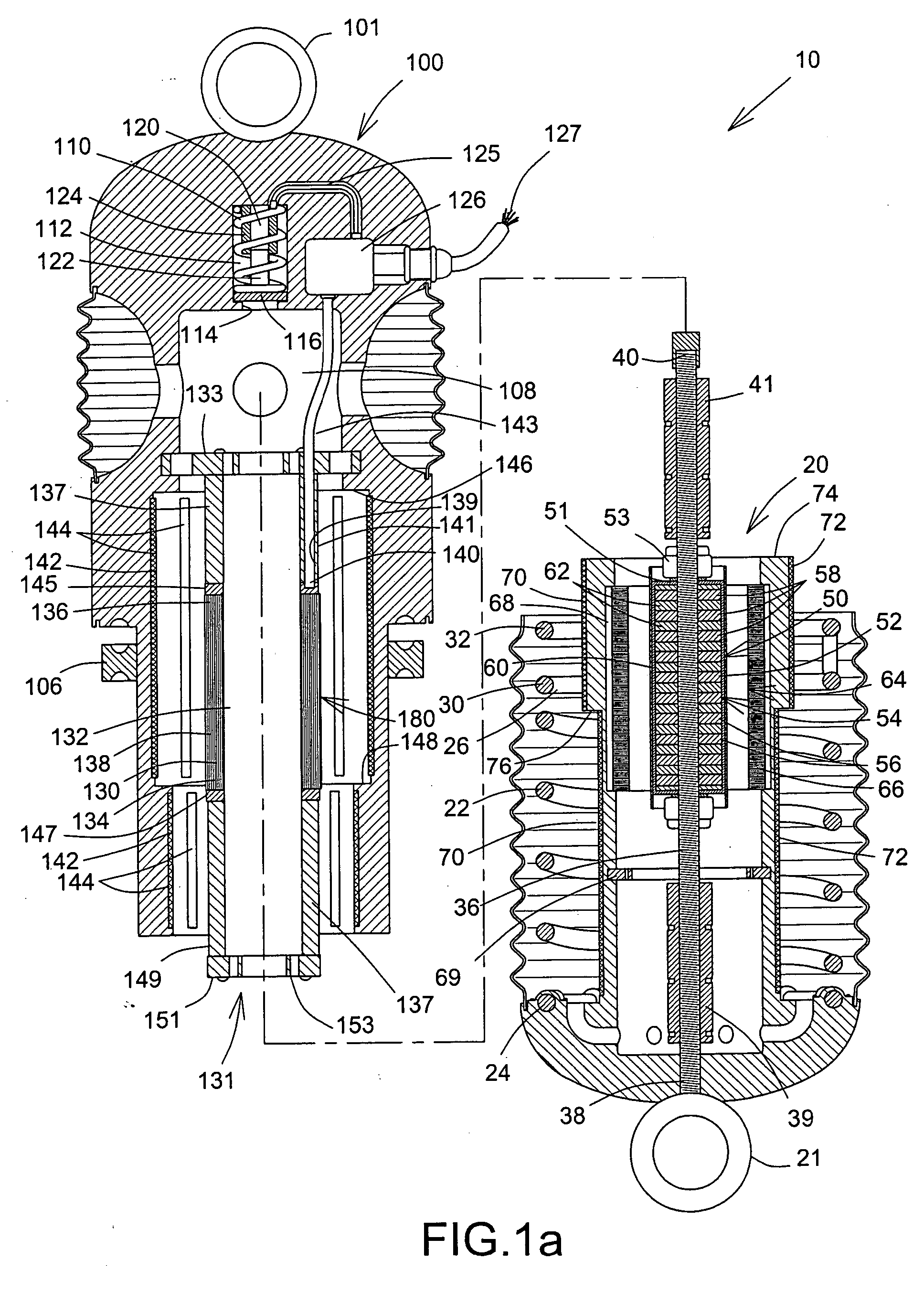

Linear generator apparatus

InactiveUS20060125325A1Conducive to recuperationVarious typesAuxillary drivesElectrotherapyFree zoneReciprocating motion

Owner:BEAULIEU GERALD

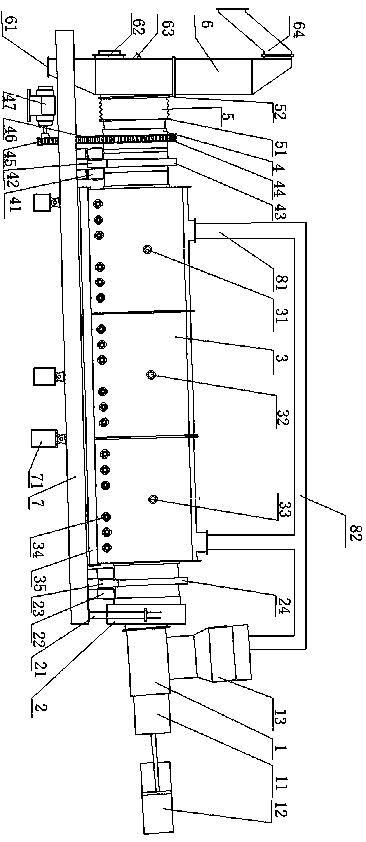

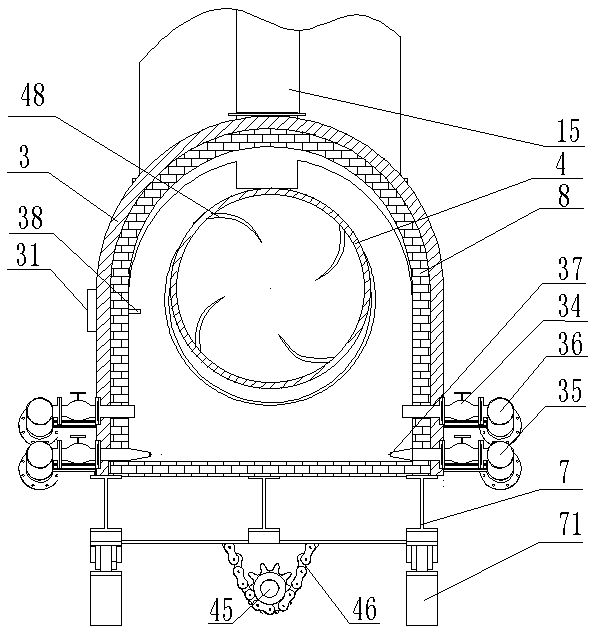

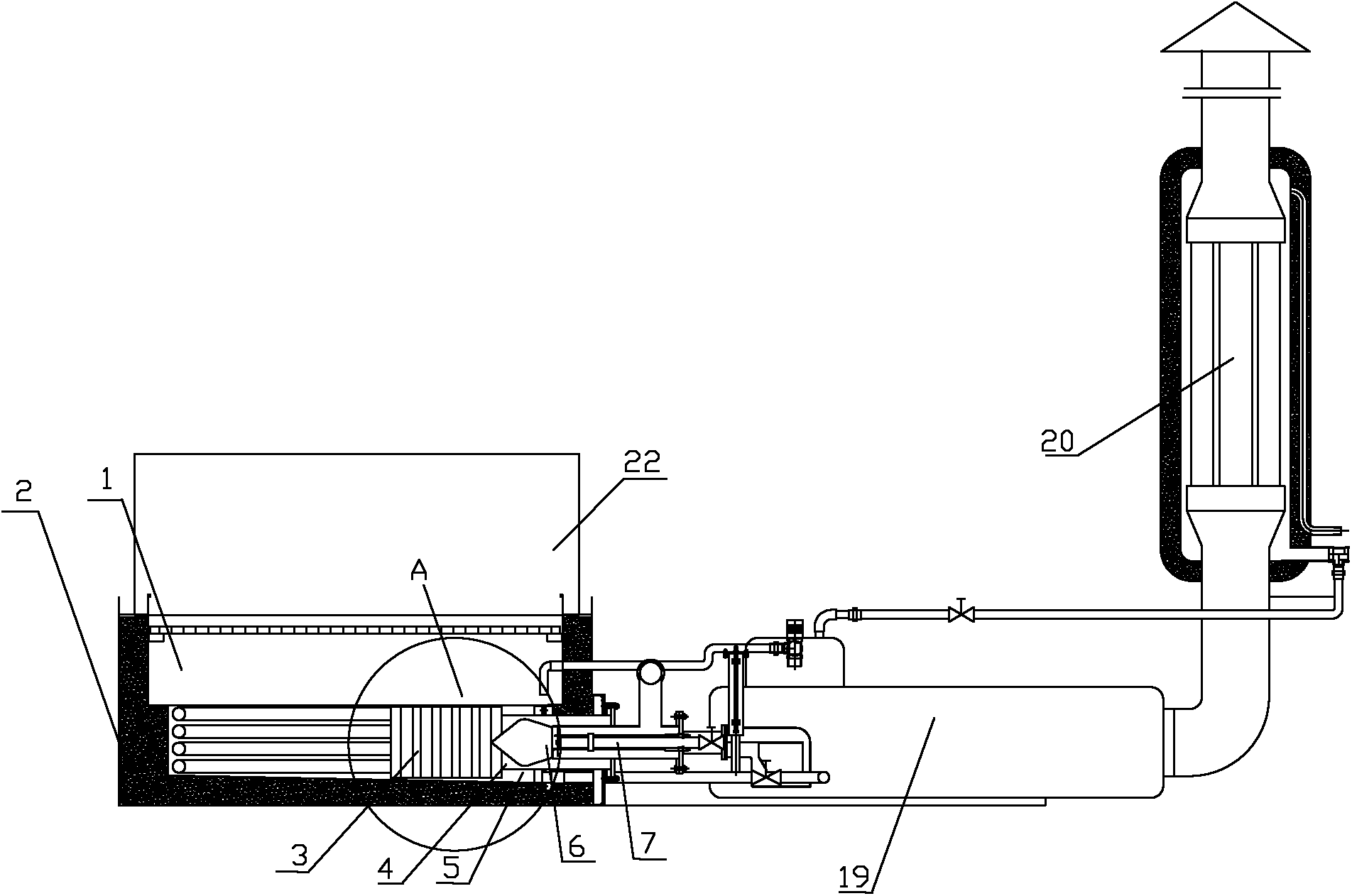

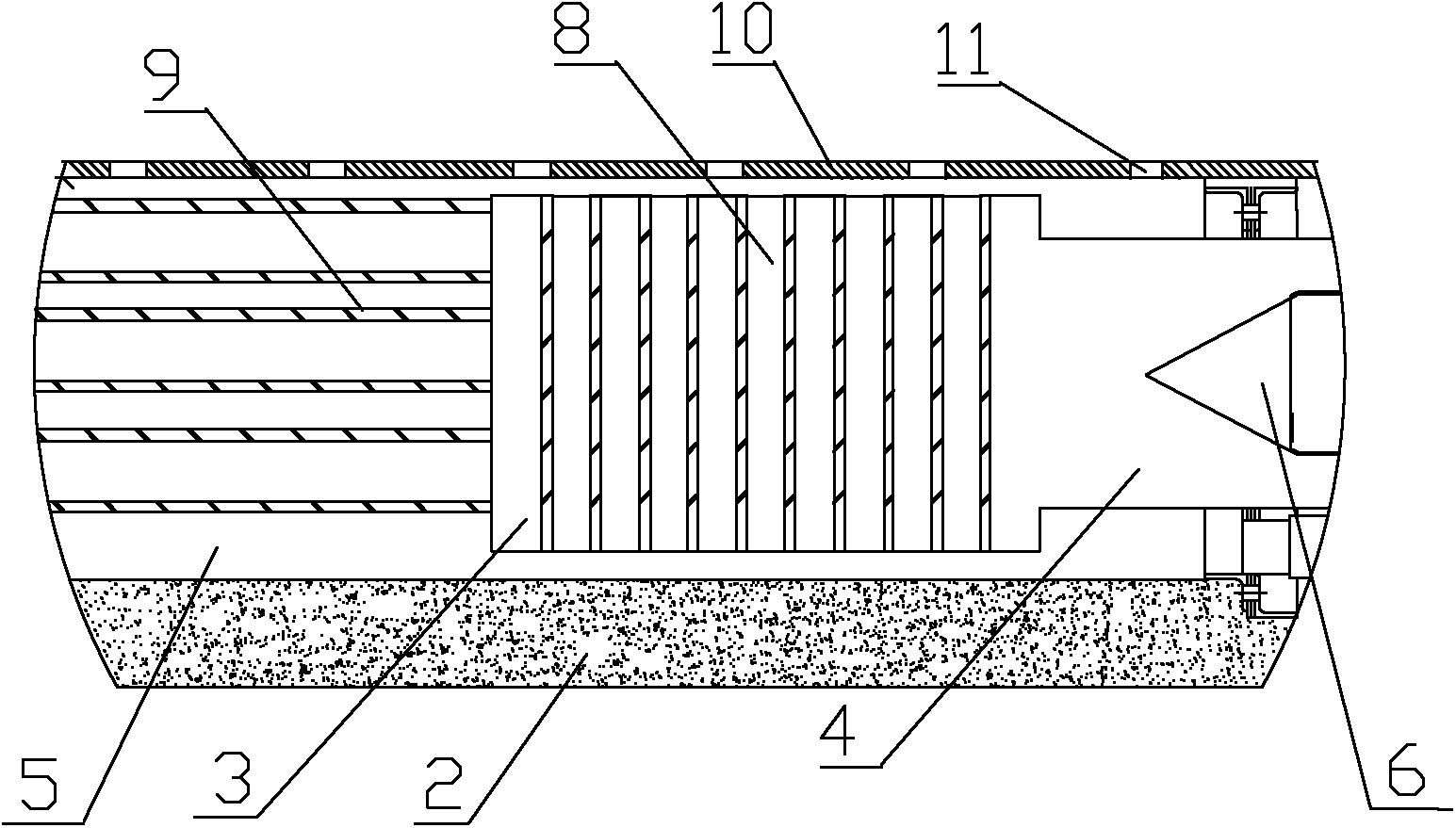

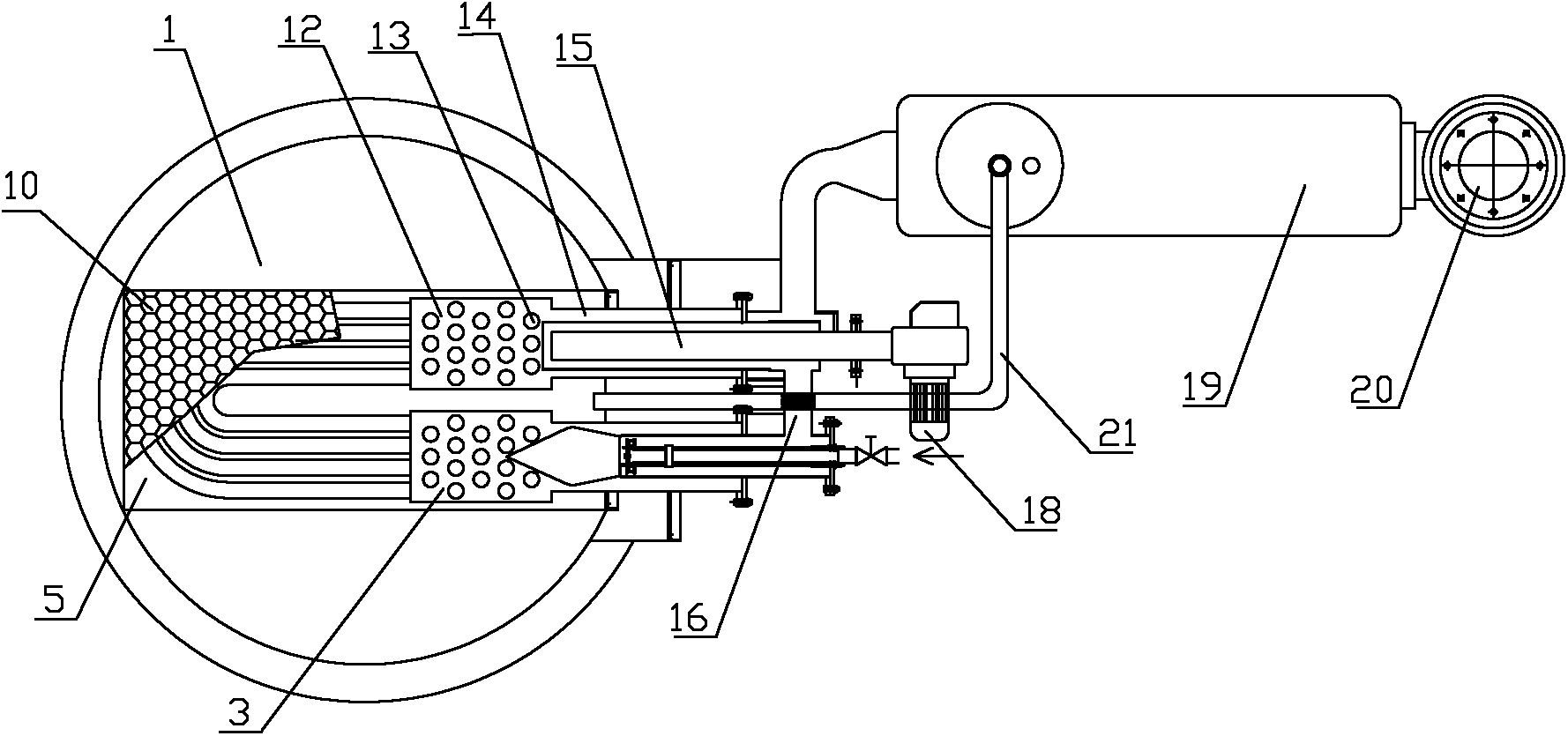

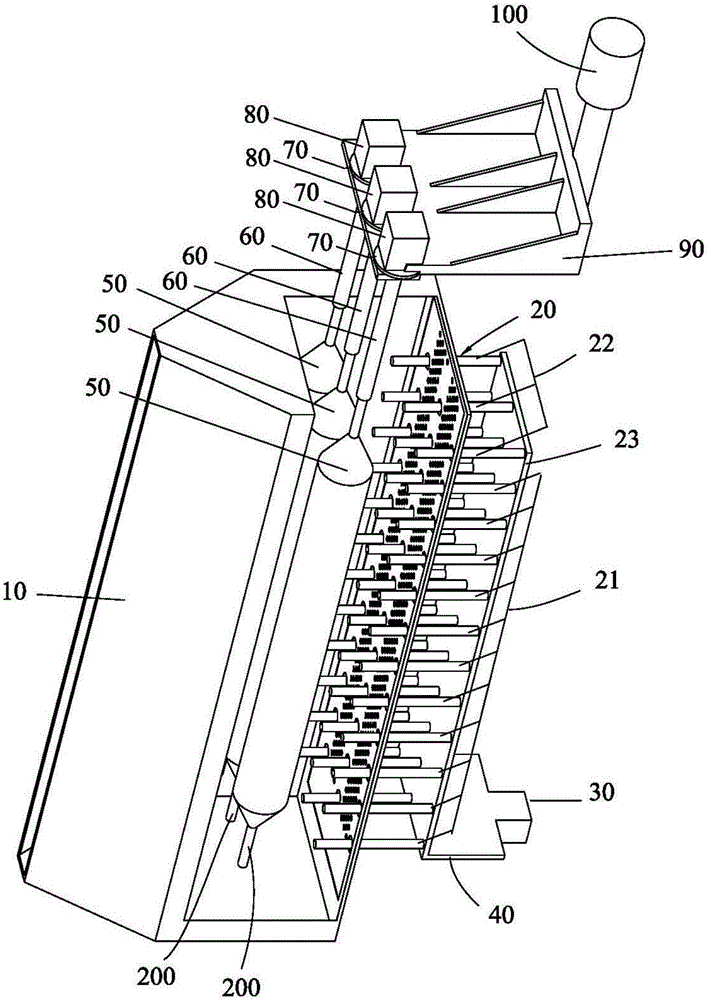

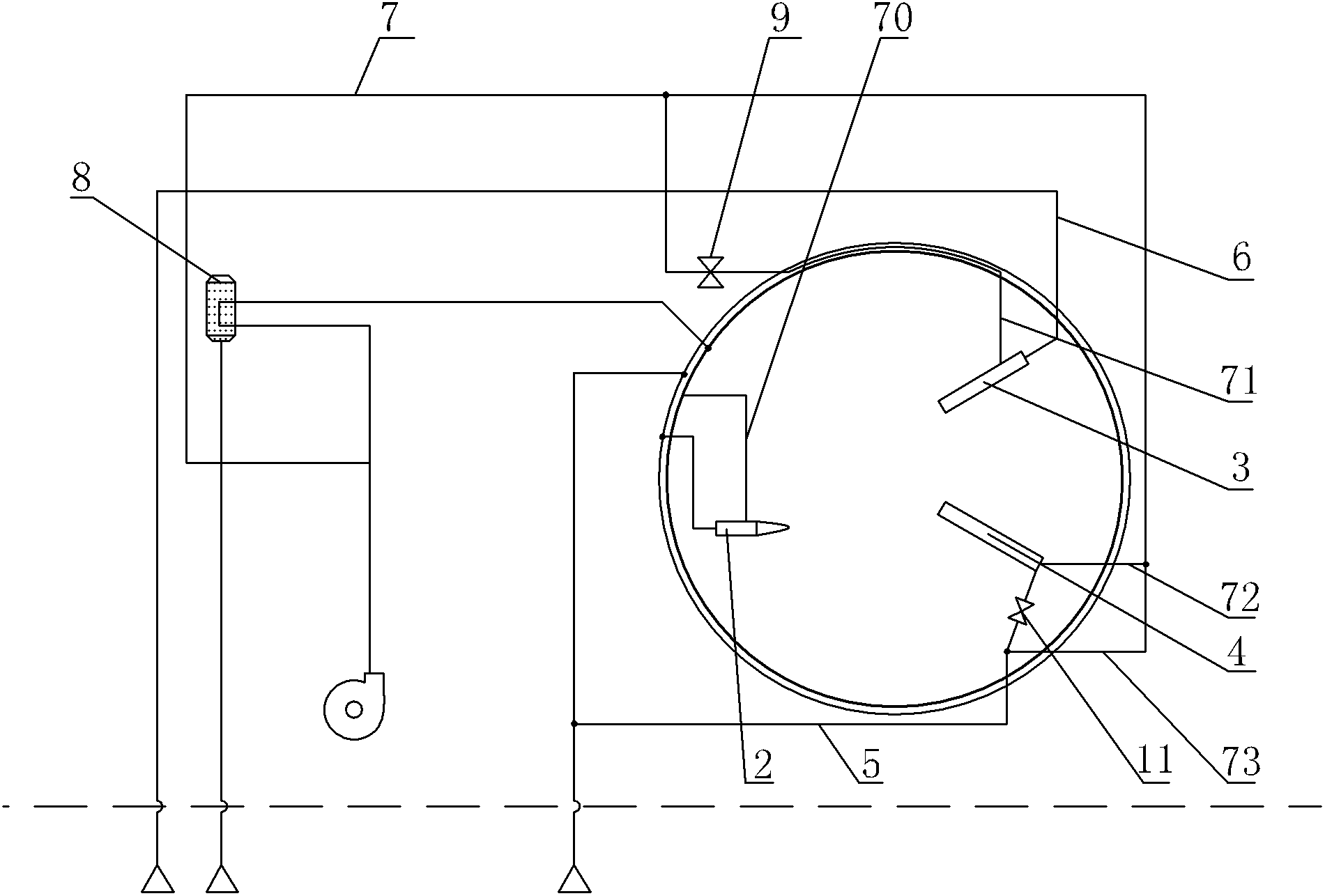

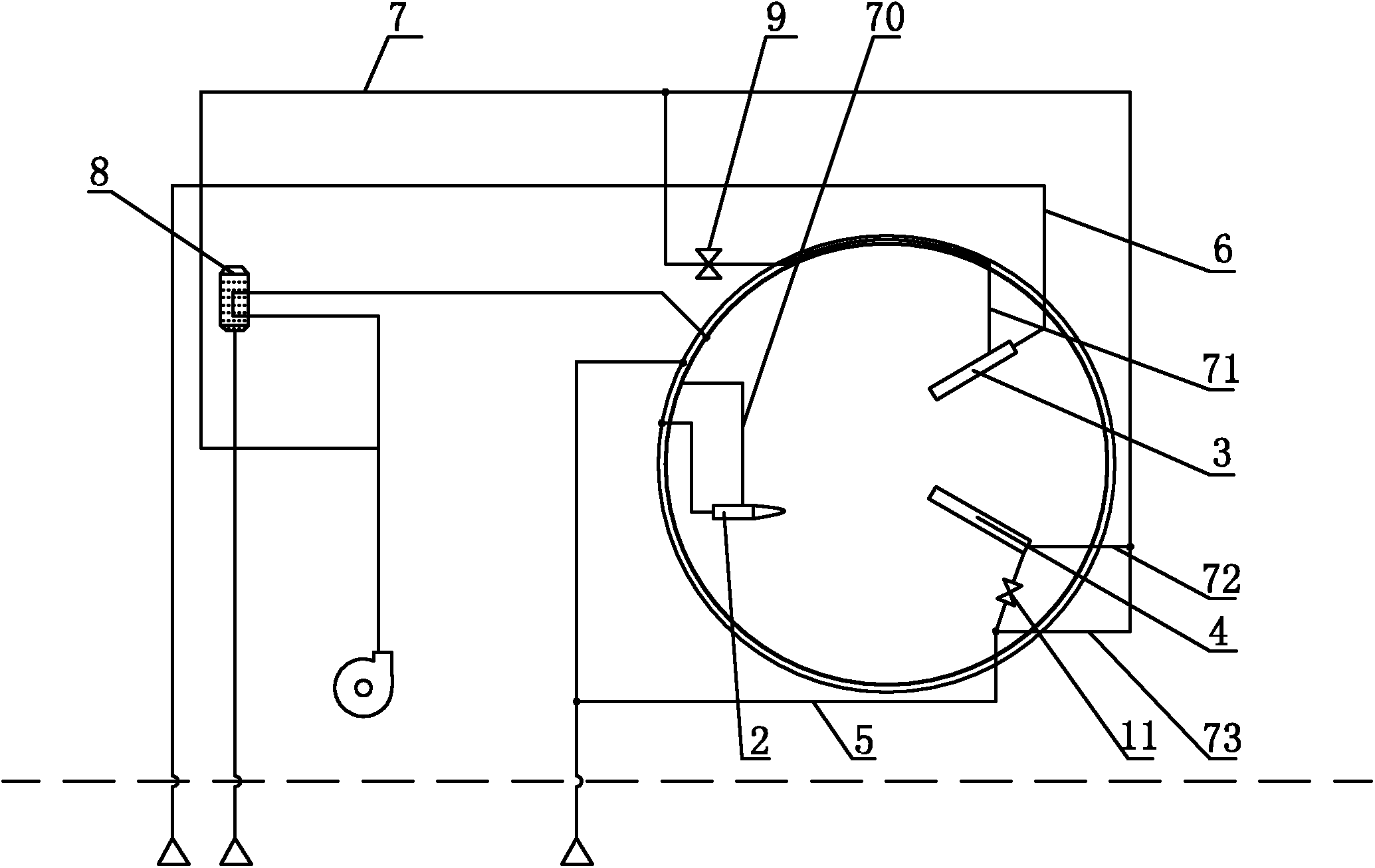

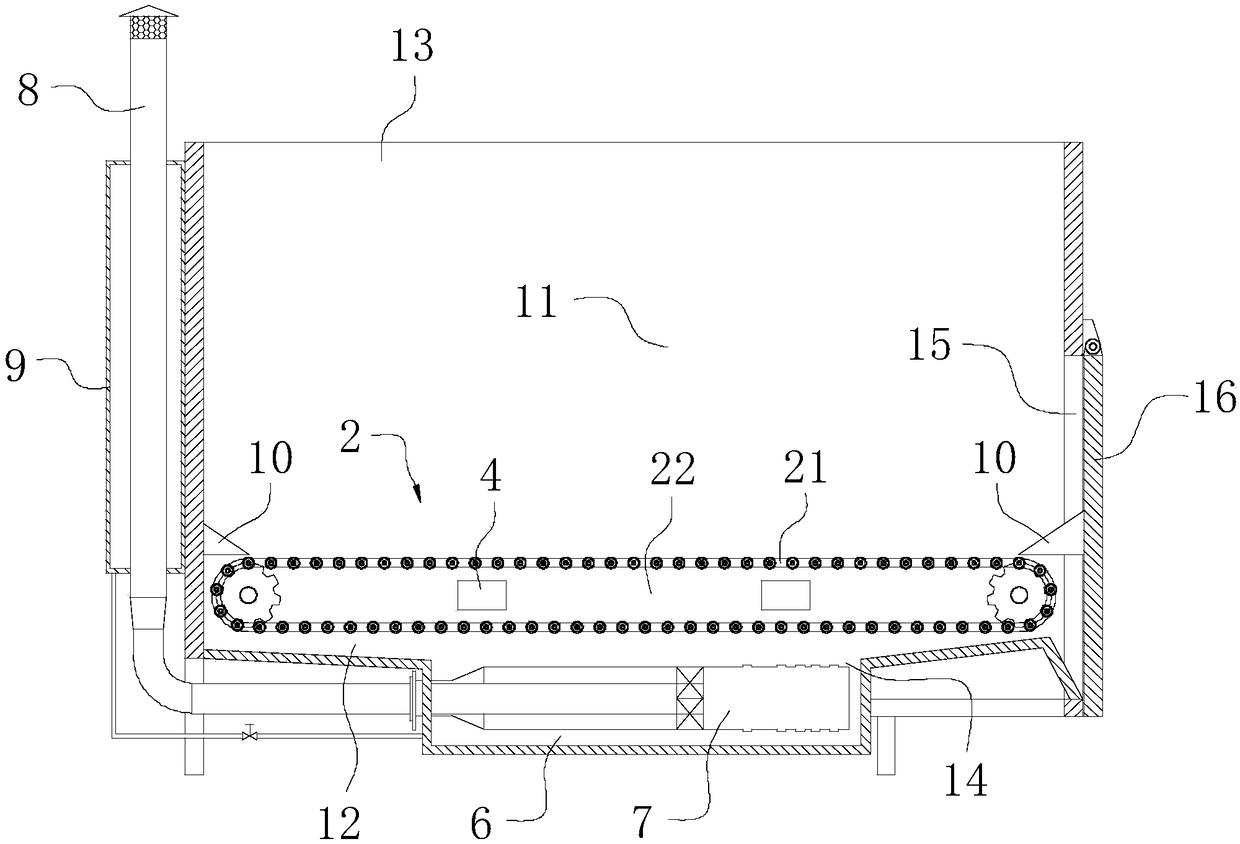

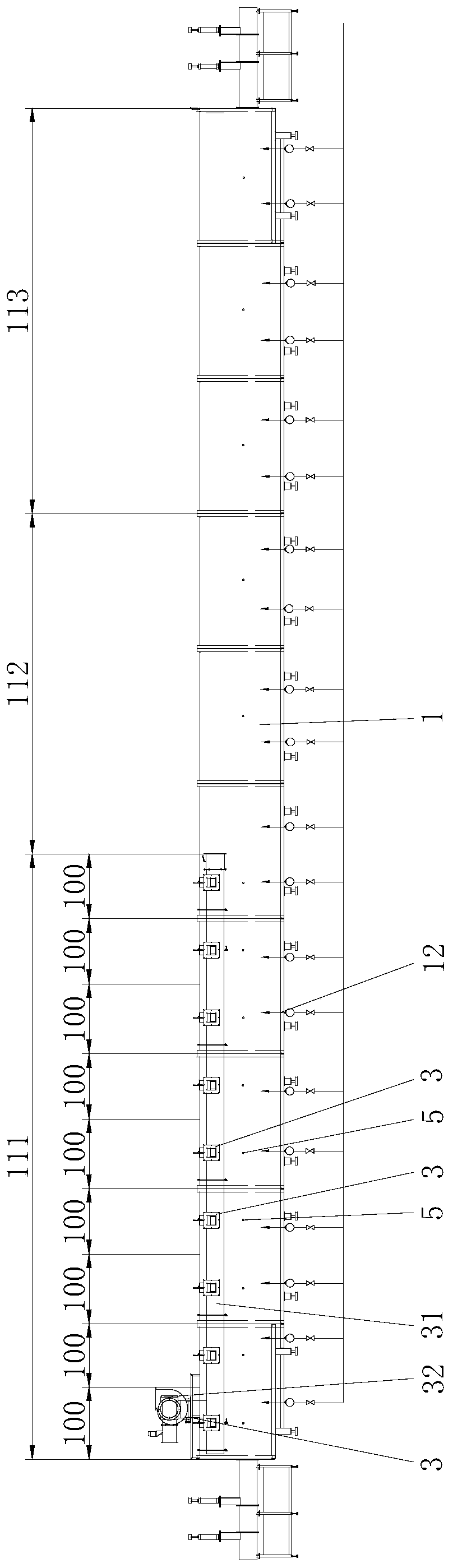

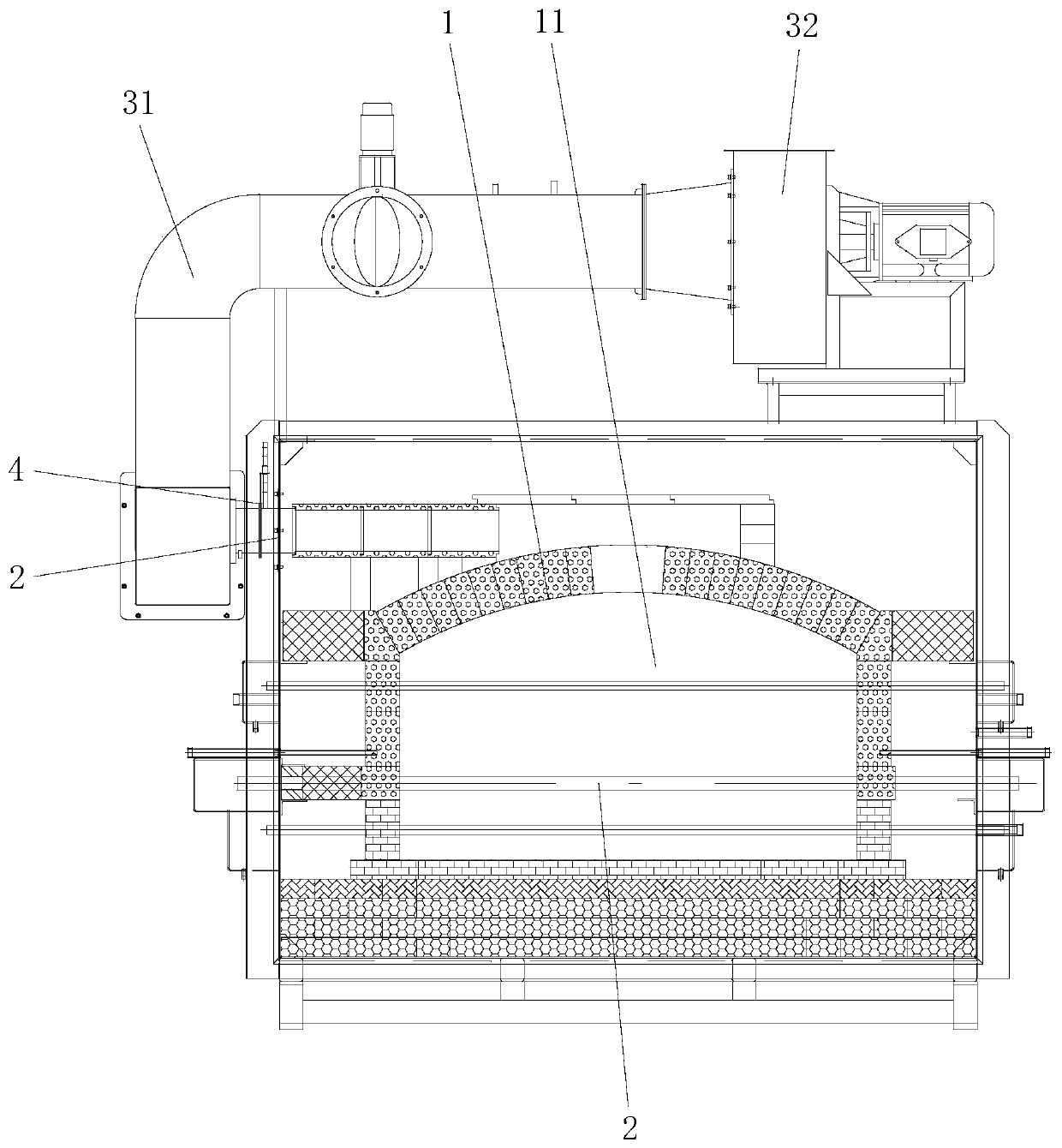

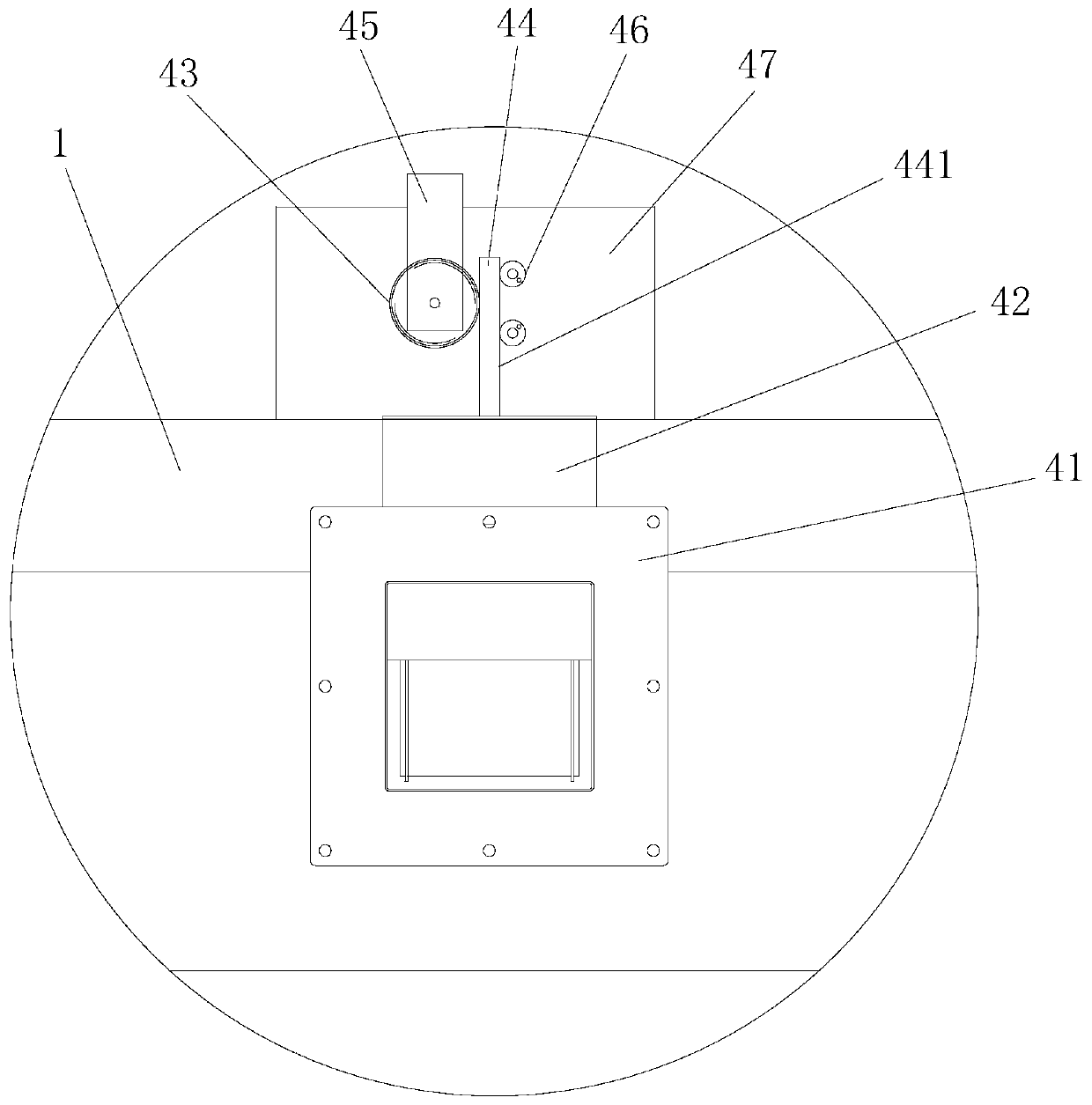

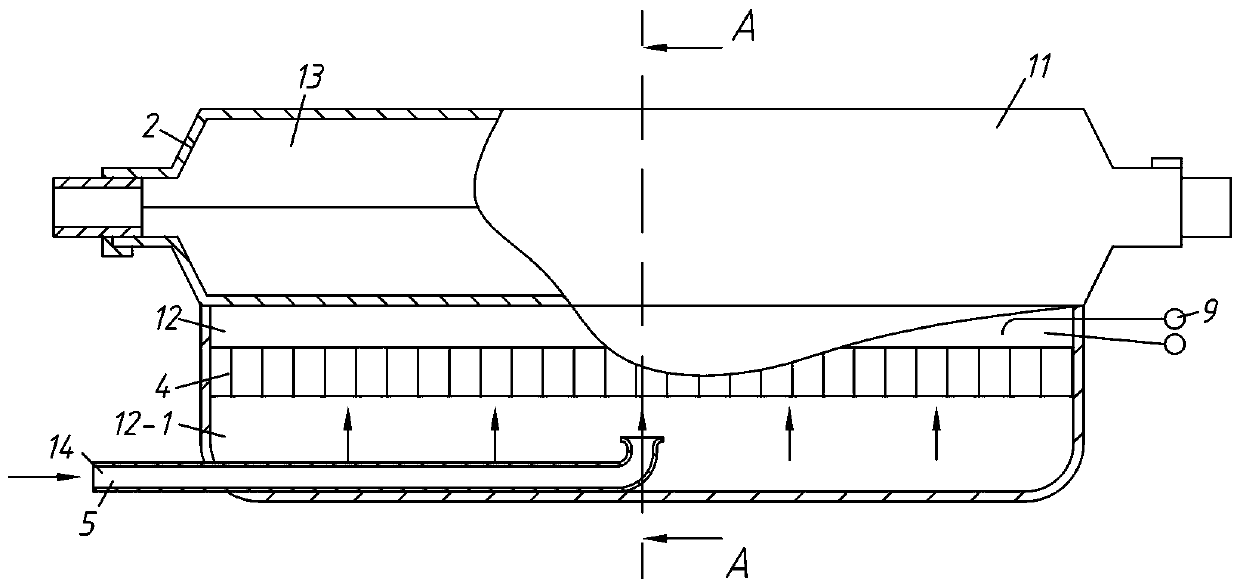

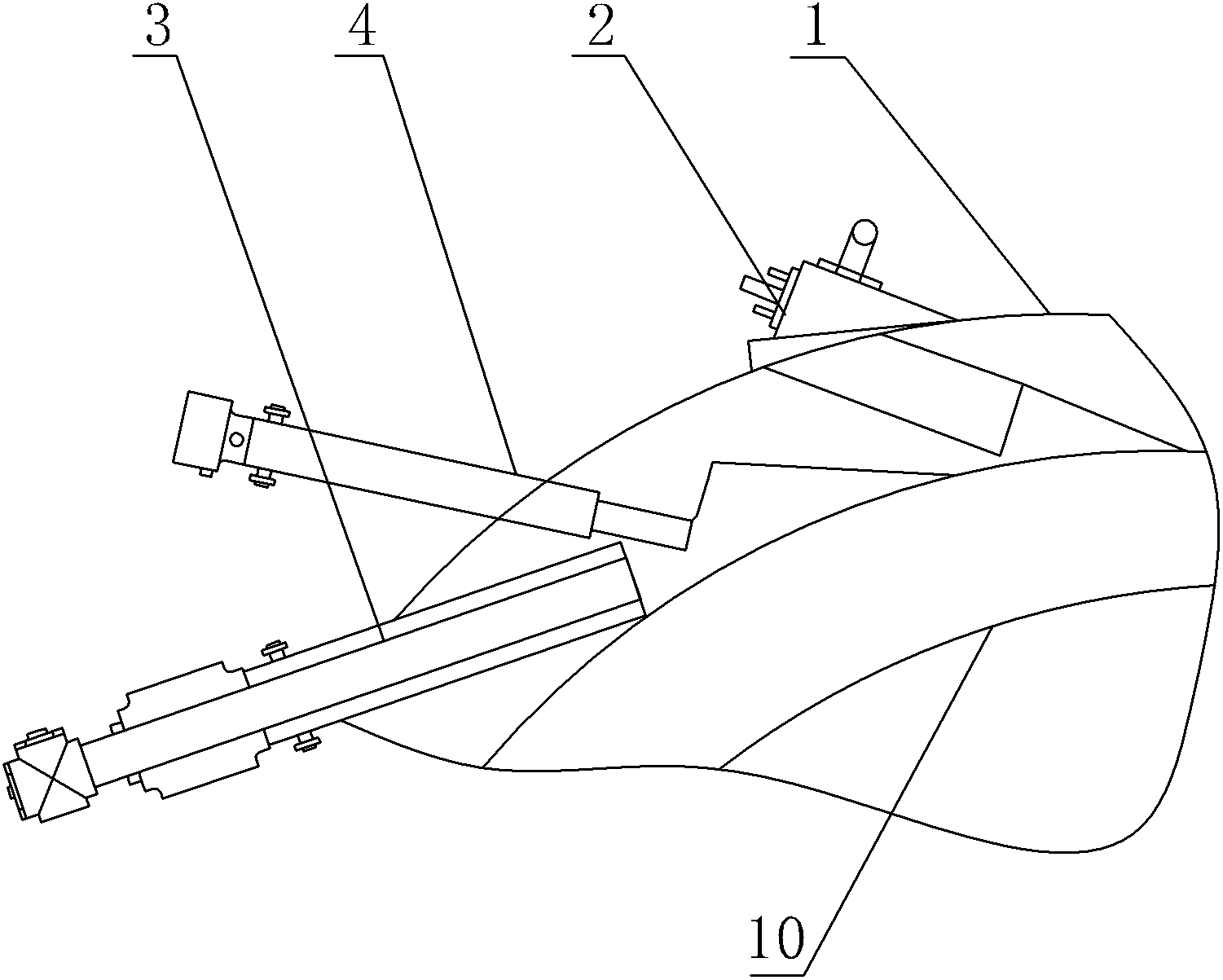

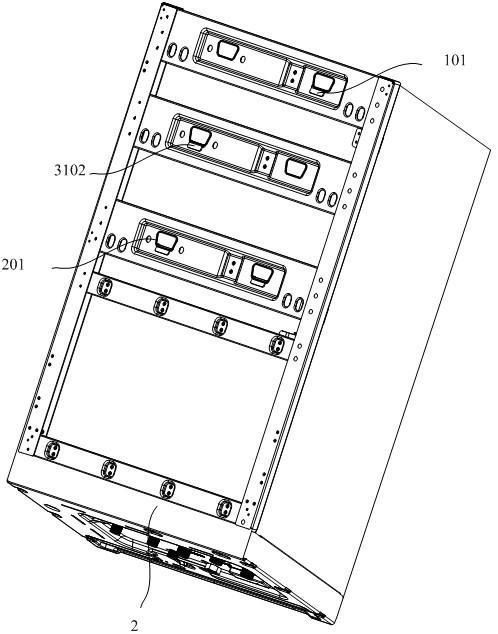

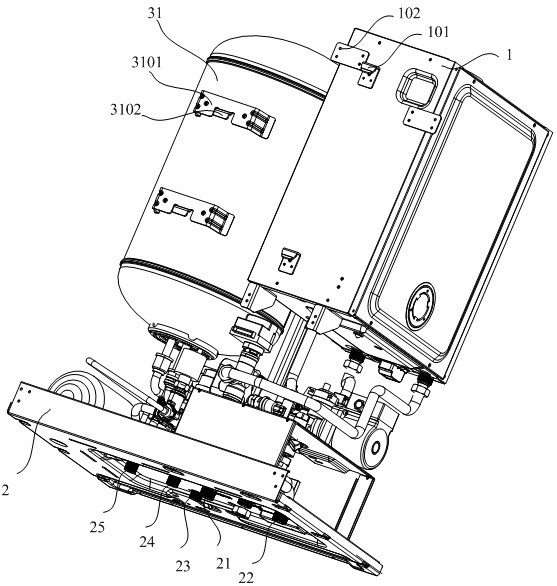

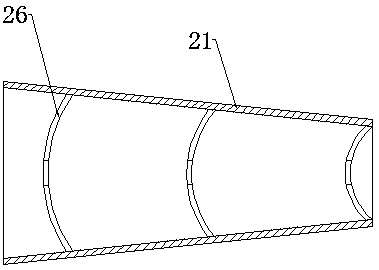

Zoned-temperature-control rotary continuous pyrolyzing and carbonizing device for biomass

ActiveCN105505416AEasy to moveSave gas consumptionBiofuelsIndirect heating destructive distillationTemperature controlEngineering

The invention discloses a zoned-temperature-control rotary continuous pyrolyzing and carbonizing device for biomass. The device comprises a kiln and a rotary furnace arranged in the kiln. The rotary furnace slowly rotates; a furnace head is installed at the head end of the rotary furnace, a furnace tail is installed at the tail end of the rotary furnace, and the furnace head is connected with a feeding device; the rotary furnace is sequentially divided into a plurality of zones in the length direction of a furnace body, independent temperature measuring devices are arranged in the portions, in all the zones, of the kiln, and a plurality of ignition devices, a plurality of gas pipes and a plurality of oxidant gas pipes are further arranged in the portions, in all the zones, of the kiln; flow deflectors are arranged in the rotary furnace. As the rotary furnace is divided into the zones, and the gas inflow and the air inflow in the portions, in all the zones, of the kiln are controlled to carry out zoned temperature control, the different temperatures at all the zones of the rotary furnace can be independently controlled, energy can be fully saved, and carbonizing efficiency can be improved; due to rotation of the rotary furnace and guide of the flow deflectors, straw slowly rotates forwards in the rotary furnace, and therefore the drying process, the pre-carbonizing process and the carbonizing process of the straw are achieved in the rotary furnace.

Owner:江苏联兴成套设备制造有限公司

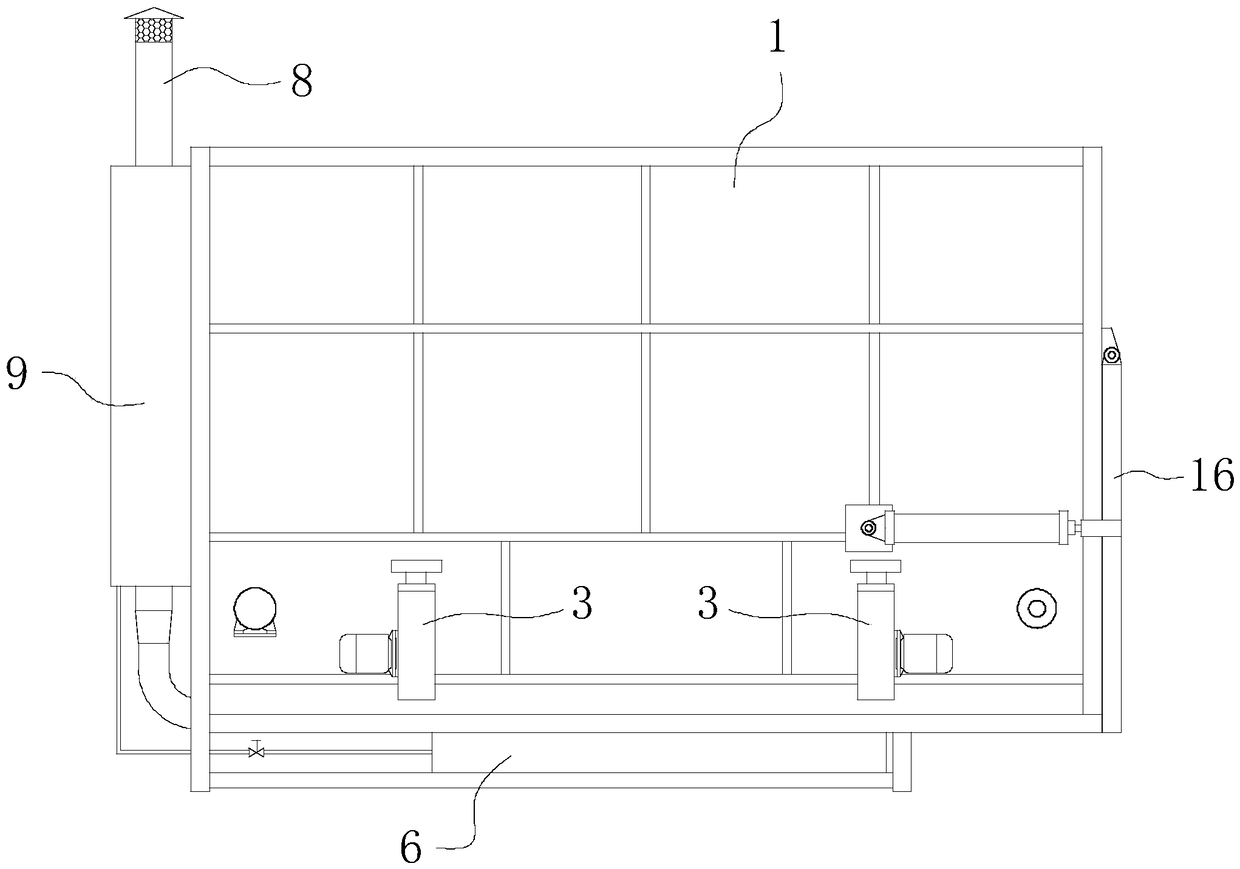

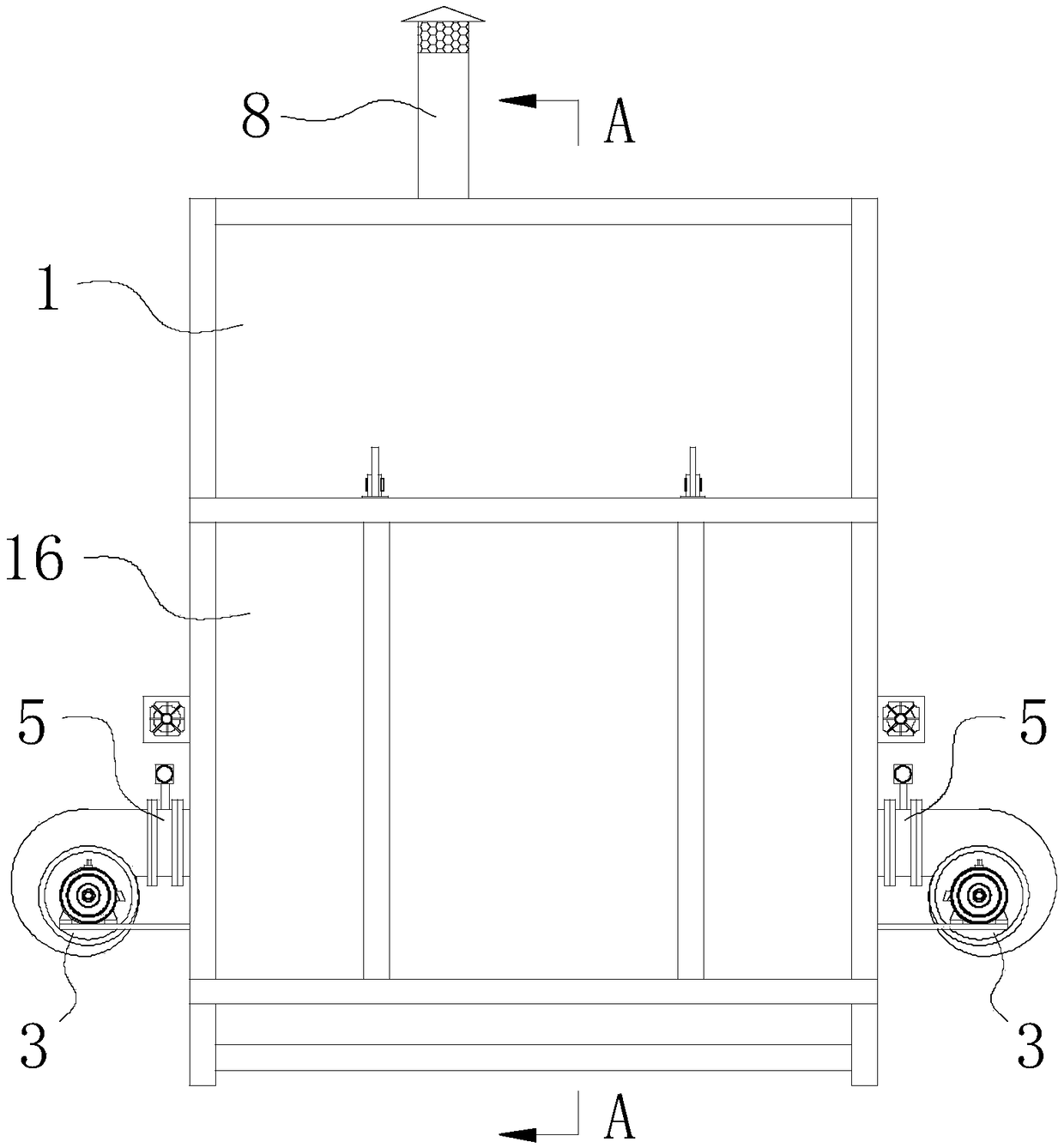

Energy-saving steaming and boiling system

ActiveCN102559432AImprove absorption and utilization efficiencyReduce consumptionFood processingAlcoholic beverage preparationCombustion chamberEngineering

The invention discloses a steaming and boiling system, which is particularly suitable for boiling water at a pot bottom to generate steam during a food steaming and boiling heat process. The invention provides an energy-saving steaming and boiling system capable of increasing the heat exchange area and improving the heat utilization efficiency. The energy-saving steaming and boiling system comprises a steaming and boiling pot and a combustion chamber arranged below the steaming and boiling pot, wherein a heat exchange water tank is mounted below the steaming and boiling pot, and an inner cavity of the heat exchange water tank is communicated with the inside of the steaming and boiling pot; a high-temperature heat exchange chamber is arranged in the heat exchange water tank, and a closed structure is formed between an inner cavity of the high-temperature heat exchange chamber and the inner cavity of the heat exchange water tank; the inner cavity of the high-temperature heat exchange chamber is communicated with the combustion chamber; a smoke outlet is further arranged on the high-temperature heat exchange chamber; high-temperature heat exchange tubes are mounted and configured in the high-temperature heat exchange chamber, vertically penetrate upper and lower walls of the high-temperature heat exchange chamber, and are communicated with the inner cavity of the heat exchange water tank; and a combustion engine is mounted in the combustion chamber, and the high-temperature heat exchange tubes are mounted in front of a burner of the combustion engine. The energy-saving steaming and boiling system can reduce energy consumption, decrease exhaust emission and lower production cost.

Owner:四川华宇瑞得科技有限公司

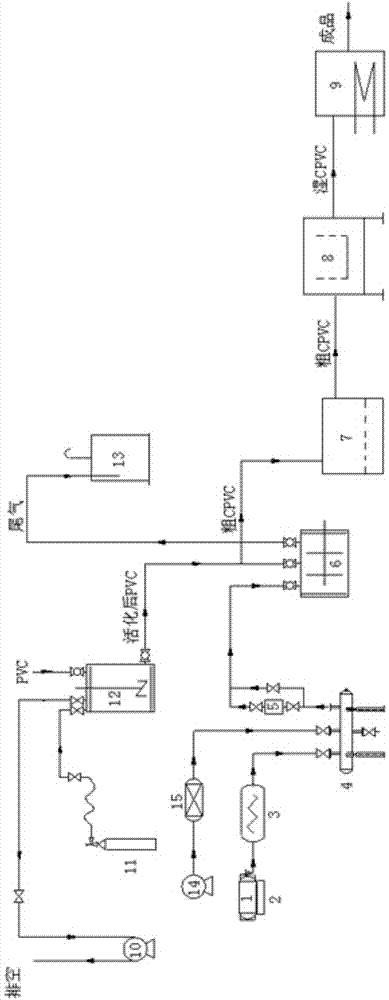

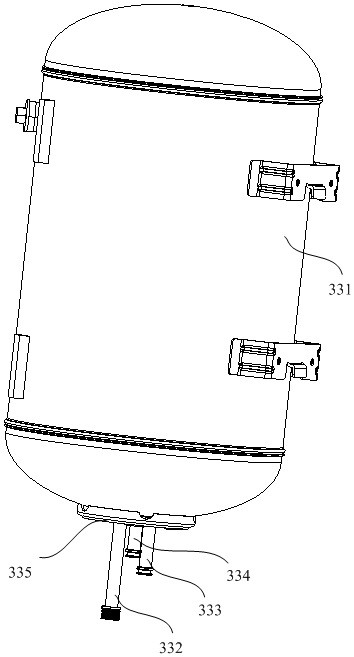

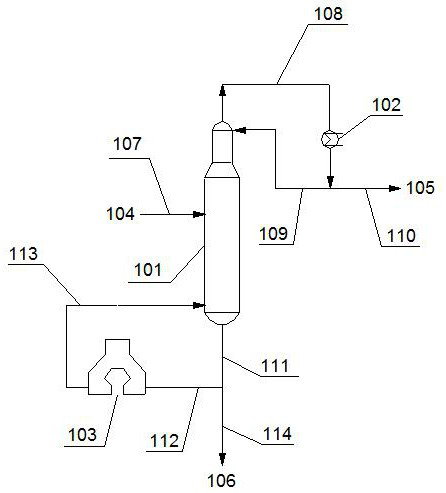

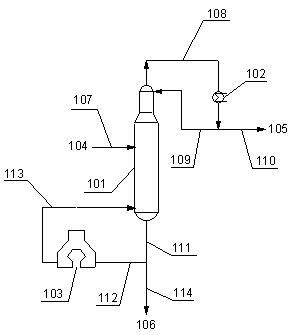

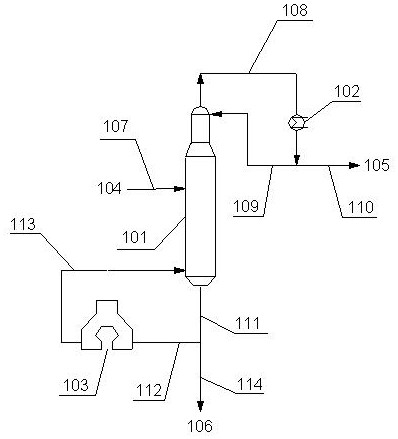

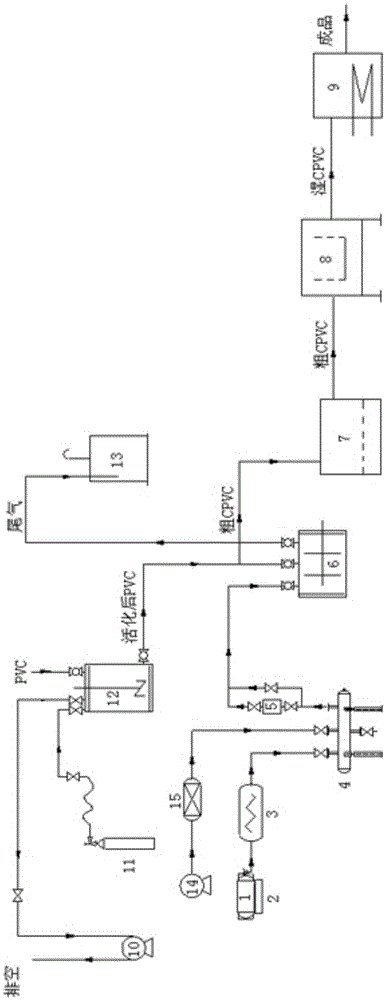

Reaction system and method for intermittent production of chlorinated polyvinyl chloride

The invention discloses a reaction system and method for intermittent production of chlorinated polyvinyl chloride. The reaction system mainly comprises a liquid chlorine vaporizer, a chlorine buffer tank, an activation reactor and a chlorination reactor, wherein the chlorine buffer tank is connected between the liquid chlorine vaporizer and the chlorination reactor, and the activation reactor is connected to the chlorination reactor. The reaction system disclosed by the invention is suitable for gas-solid phase chlorination reaction of polyvinyl chloride and other powder, can be singly used as a chlorination reaction system, can be used together with other chlorination systems, and has very good using flexibility. The reaction system and method for the intermittent production of chlorinated polyvinyl chloride are low in cost, high in product quality, easy in operation control and high in energy source utilization ratio, reduce the production cost, and can improve the chlorine content in chlorinated polyvinyl chloride to be more than 65%.

Owner:中国平煤神马控股集团有限公司

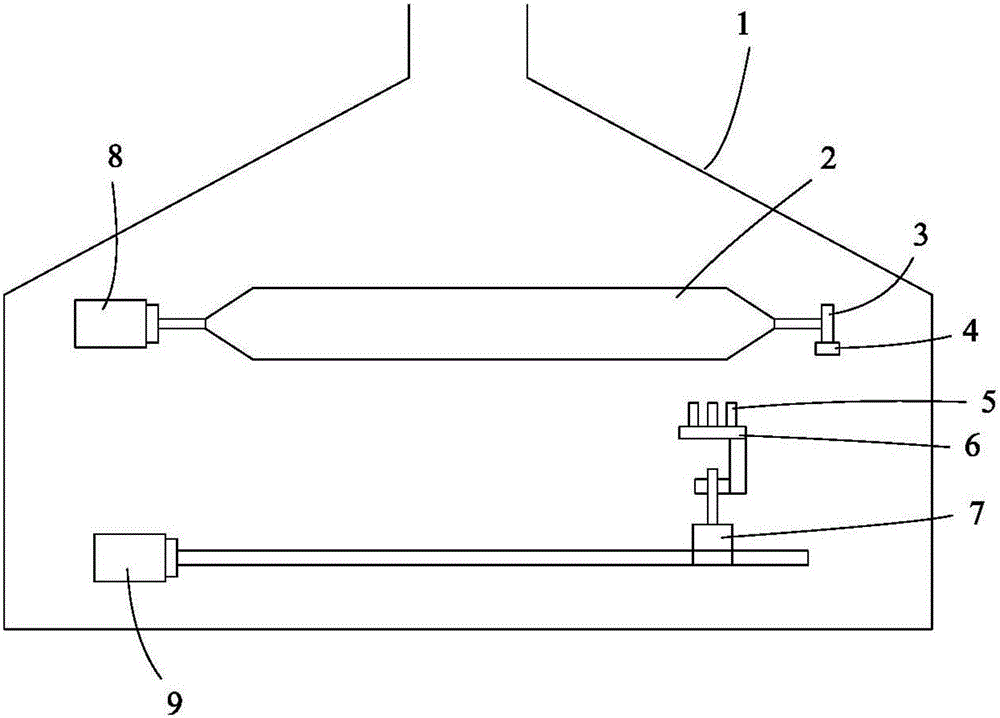

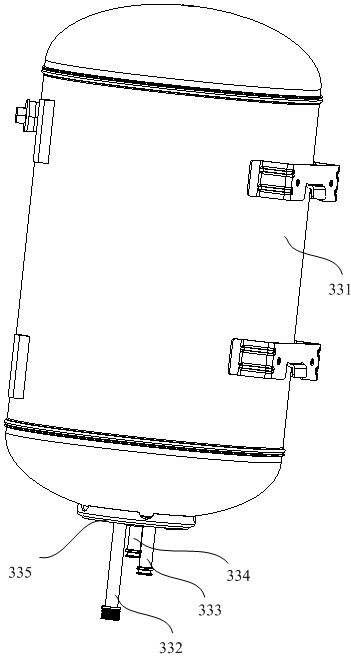

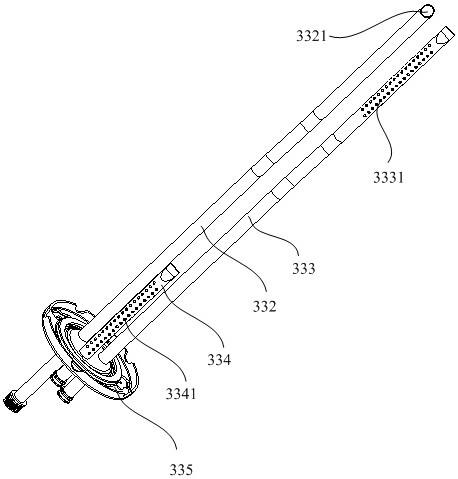

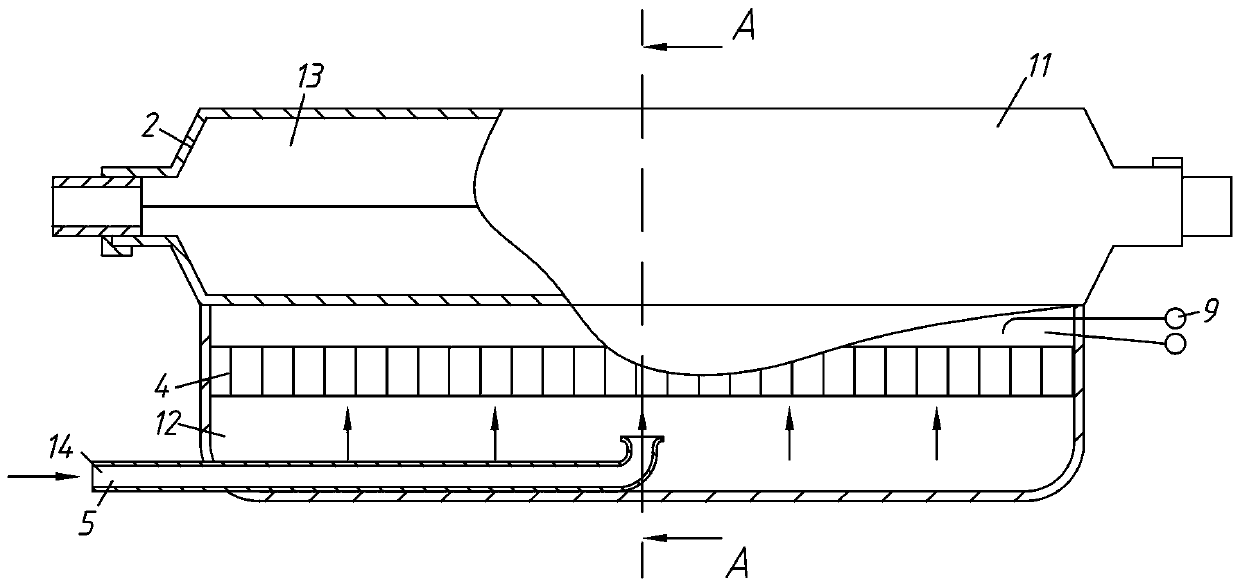

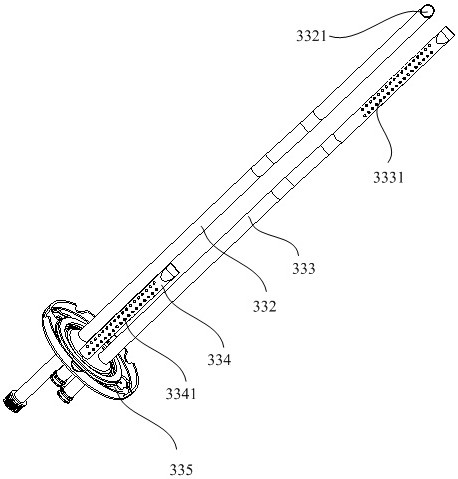

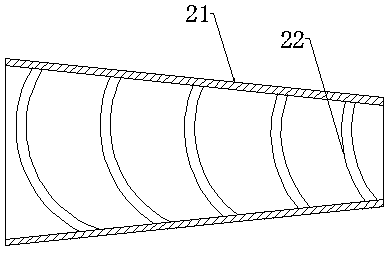

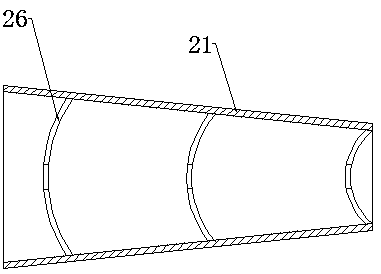

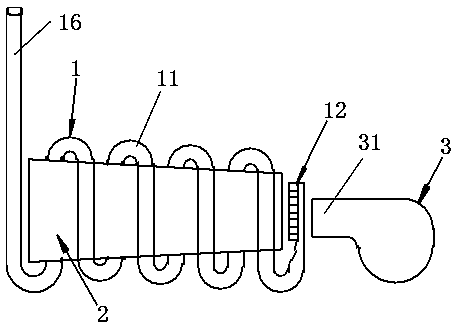

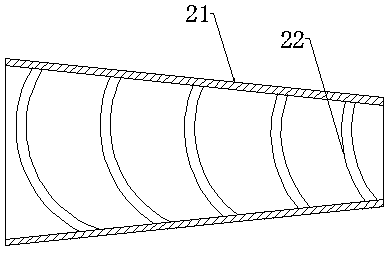

Optic fiber prefabricated loose mass deposition device and deposition method thereof

InactiveCN105776839ASave gas consumptionIncrease productivityGlass deposition burnersGlass productionEngineeringDistribution method

The invention provides an optic fiber prefabricated loose mass deposition device and a deposition method thereof. The deposition device comprises a tank, torch lamps distributed in RXC matrix, a torch lamp translation motor, a blow lamp translation platform, C target bars, C lead rods, C sensors, C rotary motors, a lifting carrier platform, and a lifting motor. The target bars extend along the first direction and are arranged above the the first blow lamp correspondingly, and the extending direction of each target bar correspond to the first blow lamp of each row in the first direction. C loose masses can be deposited in the tank, and compared with a conventional method, 3X(C-1) servo motors can be reduced, and isolation gas inside and outside of the blow lamps in the same row in the matrix distribution can share the same mass flowmeter, so that 2XRX(C-1) mass flowmeters can be saved. The matrix distribution method of the blow lamps can greatly increase production efficiency of the device, and deposition speed is RC times of the single blow lamp.

Owner:HENGTONG OPTICAL MATERIAL CO LTD

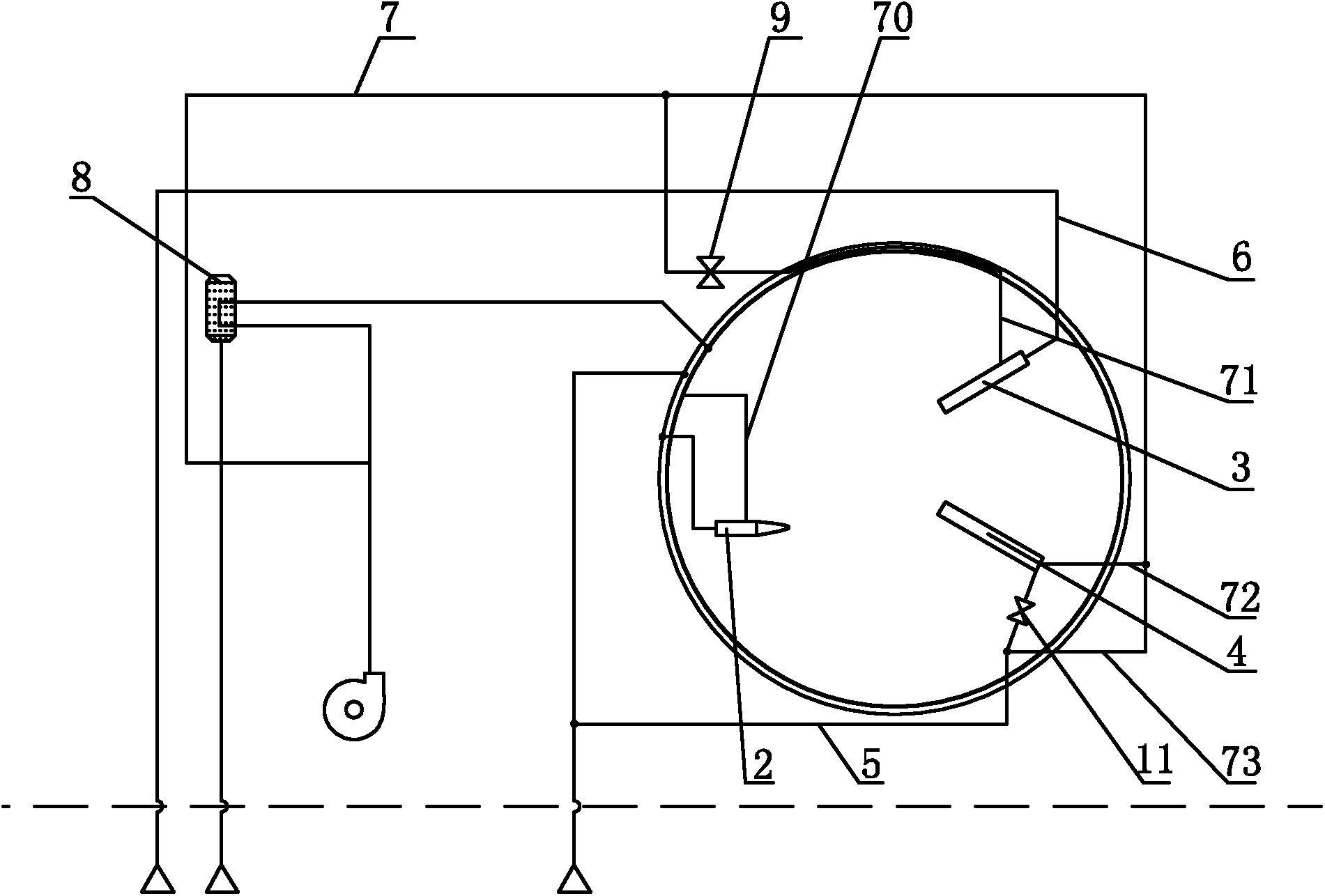

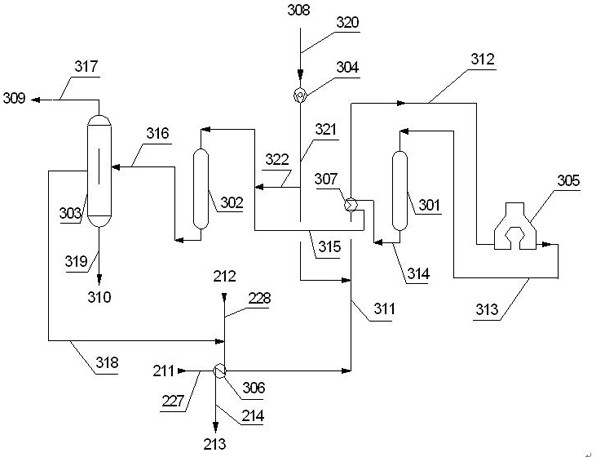

Waste hydrogen combustion system for full-hydrogen bell-type furnace used for bright annealing

InactiveCN102206742AImprove heat transfer efficiencyAvoid damageFurnace typesHeat treatment furnacesCombustion chamberProcess engineering

The invention relates to a waste hydrogen combustion system for a full-hydrogen bell-type furnace used for bright annealing. The waste hydrogen combustion system comprises a main burner, a waste hydrogen burner and an auxiliary burner which are fixed on a shell, and a gas pipeline, a waste hydrogen pipeline and an air pipeline which are distributed on the shell, wherein the main burner is connected with the gas pipeline and the air pipeline; the waste hydrogen burner is connected with the waste hydrogen pipeline and the air pipeline; the auxiliary burner is connected with the gas pipeline andthe air pipeline; and the flame combustion direction of the waste hydrogen burner is tangent to the outer wall of an inner covered muffle and is not contacted with the outer wall of the inner coveredmuffle. The flame combustion direction of the waste hydrogen burner can ensure the best heat conduction efficiency and avoid damage or deformation caused by overhigh local temperature due to direct contact of flames and a muffle cover; the auxiliary burner has two electrodes, and when the ignition failure times is greater than a set value, a combustion chamber is needed to be blown, residual hydrogen is blown, and blast is prevented; and energy loss is reduced, the using amount of gas is reduced, and the environmental pollution is lightened.

Owner:艾伯纳工业炉(太仓)有限公司

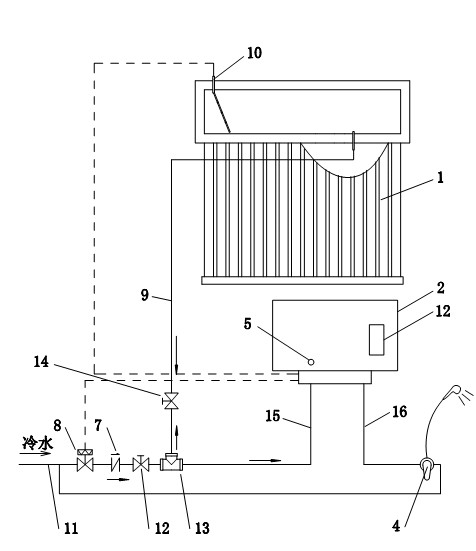

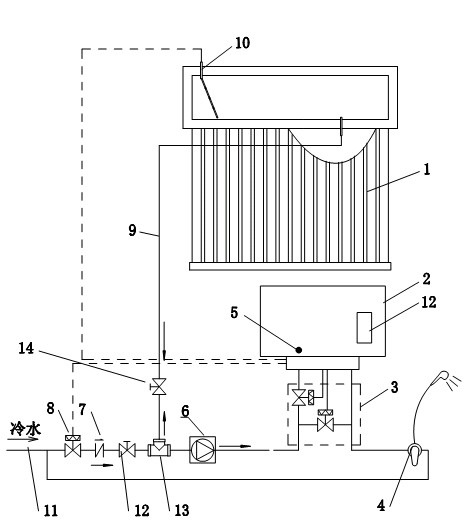

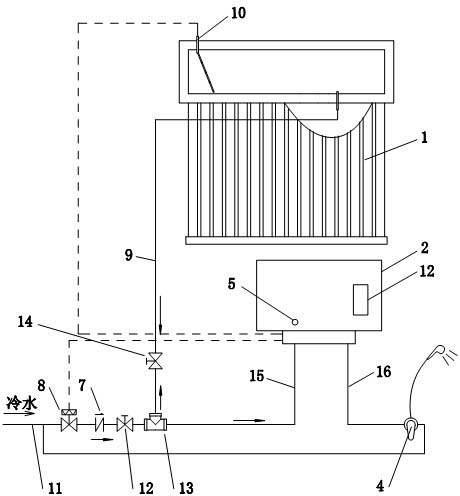

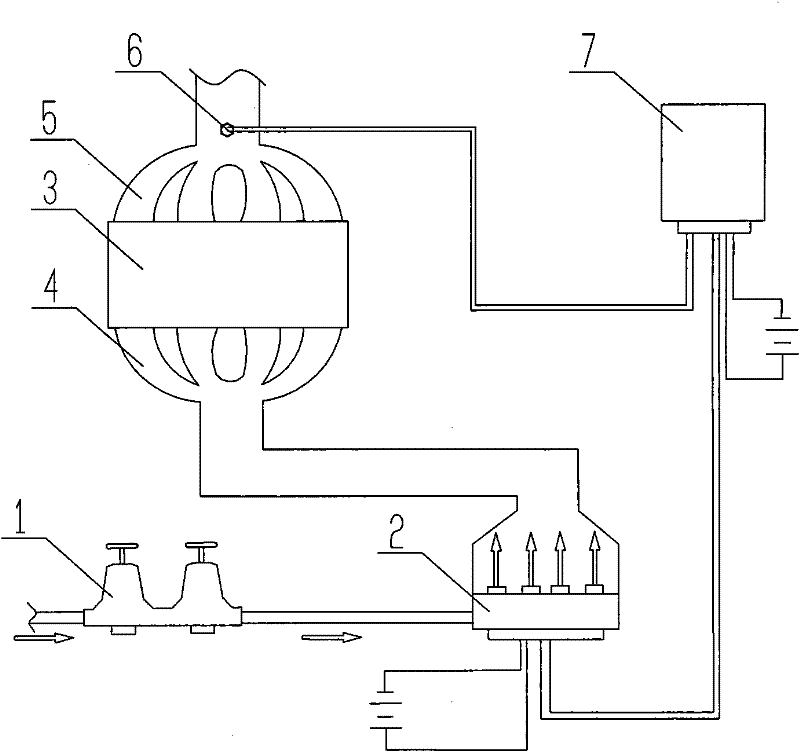

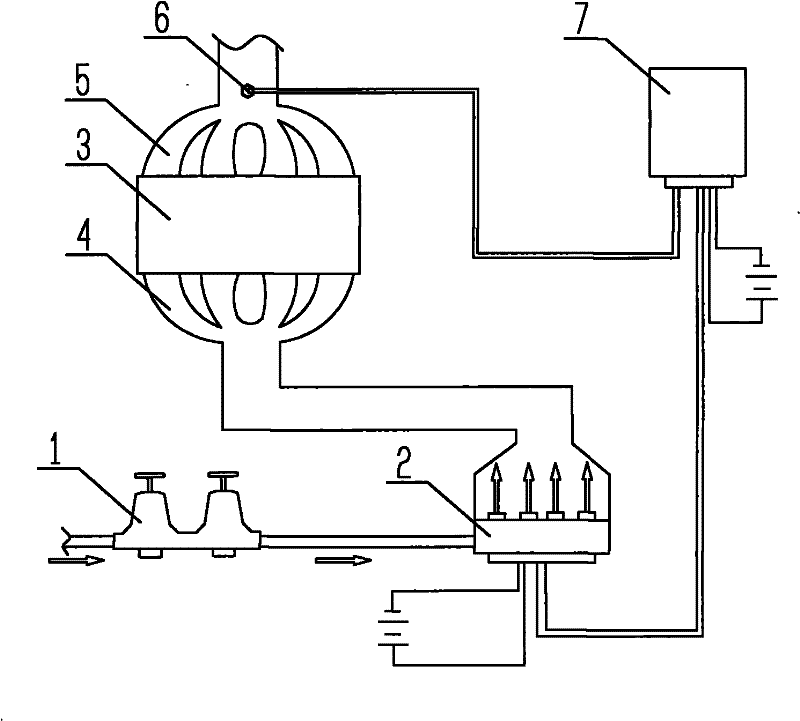

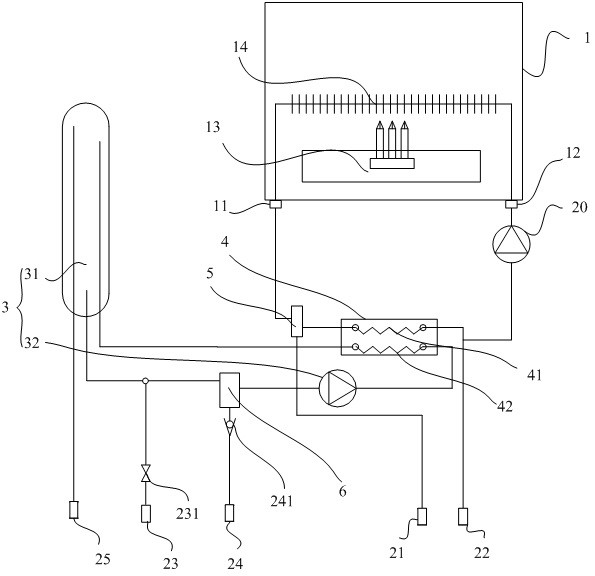

Solar water heater with gas water heater

InactiveCN102278822AStable supplySave gas consumptionSolar heat devicesSpace heating and ventilation detailsSolenoid valveSolar water

The invention relates to a solar water heater with a gas water heater, which includes a solar water heater and a cold water inlet pipe, and is characterized in that it also includes a gas water heater, a solenoid valve, a three-way valve, a controller, a temperature probe and a water mixing valve, wherein the solar water heater passes through three The through valve is connected with the cold water inlet pipe, the outlet pipe of the solar water heater is connected with the inlet pipe of the gas water heater through the three-way valve, the solenoid valve is set on the cold water inlet pipe, the controller is set in the gas water heater, and the temperature probe is set in the gas water heater. On the water outlet of the water inlet pipe, the controller is electrically connected with the temperature probe and the solenoid valve respectively; the outlet pipe of the gas water heater is connected with one water inlet of the water mixing valve; Its beneficial effects are: the invention realizes that the solar water heater has hot water immediately when it is turned on, and can realize a stable supply of hot water around the clock, while maximizing the use of solar energy, the consumption of gas is greatly reduced, and a comfortable, economical, energy-saving and environment-friendly environment is realized. combined.

Owner:MIDEA GRP CO LTD

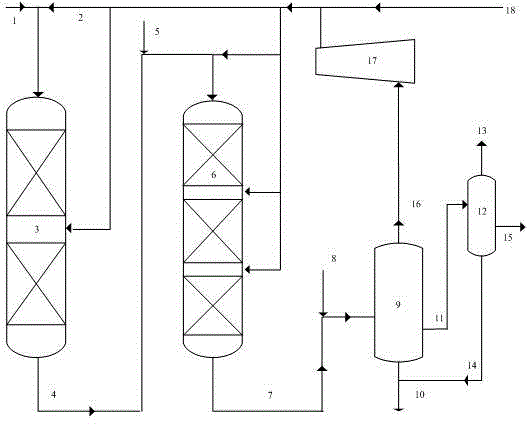

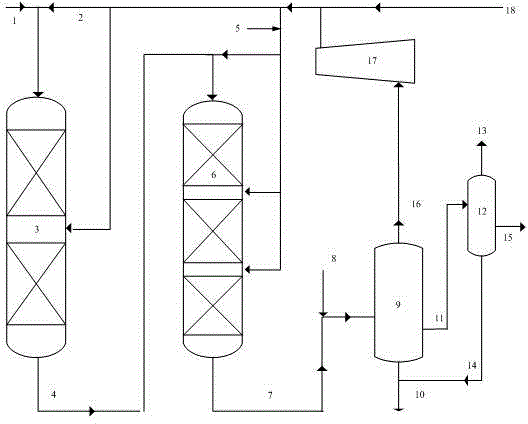

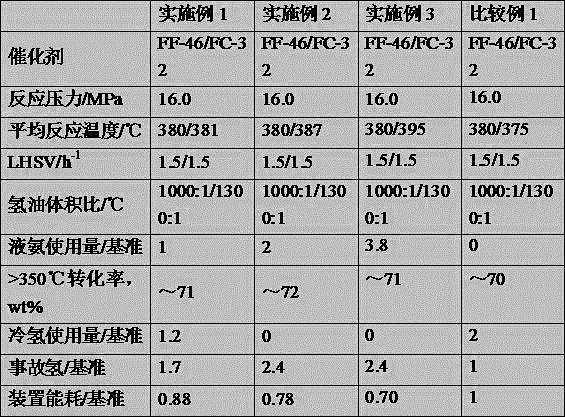

A method of improving running safety of a hydrocracking device

ActiveCN105754649AGood temperature matchingRaise the reaction temperatureTreatment with hydrotreatment processesReaction temperatureProcess engineering

A method of hydrocracking is disclosed. The method does not need any transformation on a hydrocracking device and only utilizes present procedures of the device. Passivation gas containing ammonia gas is injected into a catalyst bed layer through an inlet of a hydrocracking reactor to reduce reaction activity, the reaction temperature of a cracking catalyst is increased under the premise of not greatly changing product distribution, and the temperature of an outlet of a refining reactor and the temperature of an inlet of the cracking reactor are matched reasonably to the utmost. The method improves operation safety, flexibility and emergency incident responding capability of the device, avoids overtemperature, and reduces energy consumption of the device to a certain degree.

Owner:CHINA PETROLEUM & CHEM CORP +1

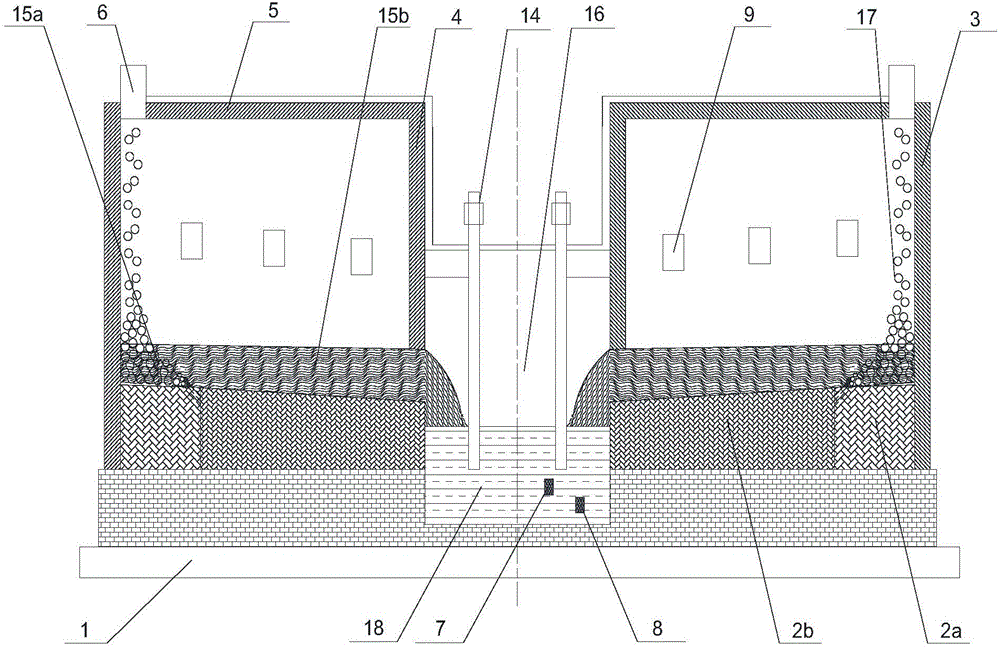

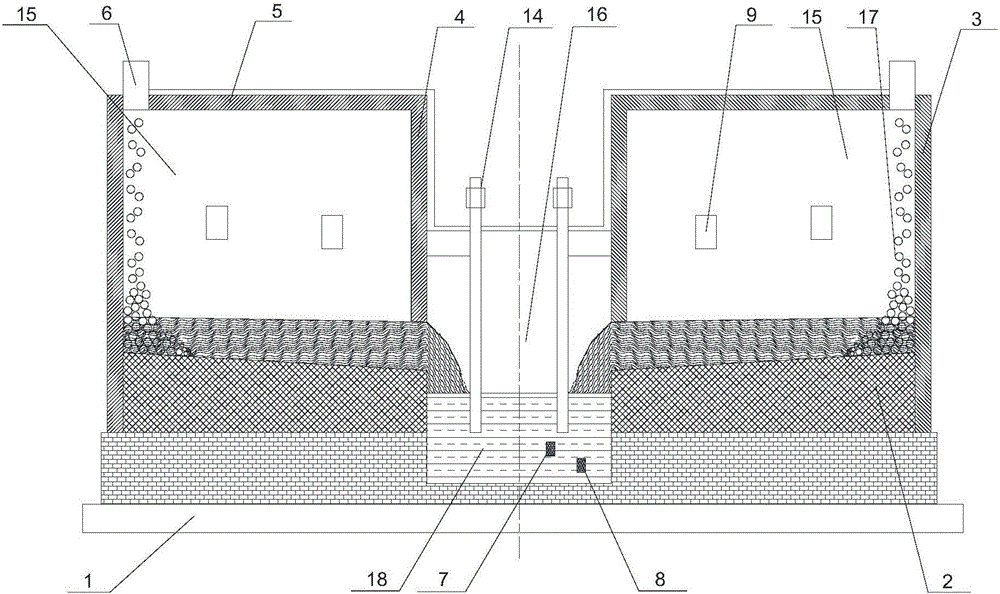

Smelting furnace heated through combination of heavy oil burning, gas burning and electric arc heating

PendingCN106500507AMelting fastPrevent oxidationCrucible furnacesWaste heat treatmentGraphite electrodeCombustor

The invention discloses a smelting furnace heated through combination of heavy oil burning, gas burning and electric arc heating. The smelting furnace comprises a furnace body arranged on a furnace base, the furnace body comprises a side wall, a furnace top, and a fire resistant furnace bottom arranged on the furnace base; a hearth of the furnace body is divided into two parts including a smelting area and a settling area, a furnace bottom of the settling area is lower than a furnace bottom of the smelting area, the furnace bottom of the smelting area adopts an inclined type, one end, adjacent to the settling area, of the smelting area tilts down and is communicated with the settling area, a feed port is formed in a furnace top at one end, far from the settling area, of the smelting area, burners are arranged on opposite two side walls in the smelting area, a graphite electrode penetrating through the furnace top is arranged on the settling area, and a slag discharge port and a hot metal discharge port are respectively formed in the bottom of the settling area. The smelting furnace combines the advantages of gas burning heating and electric arc heating, and has the advantages of low smelting cost, environmental friendliness, high product quality, high handling capacity of single furnace, wide applicability of raw materials, high recovery rate and the like.

Owner:JIANGSU PROVINCE METALLURGICAL DESIGN INST

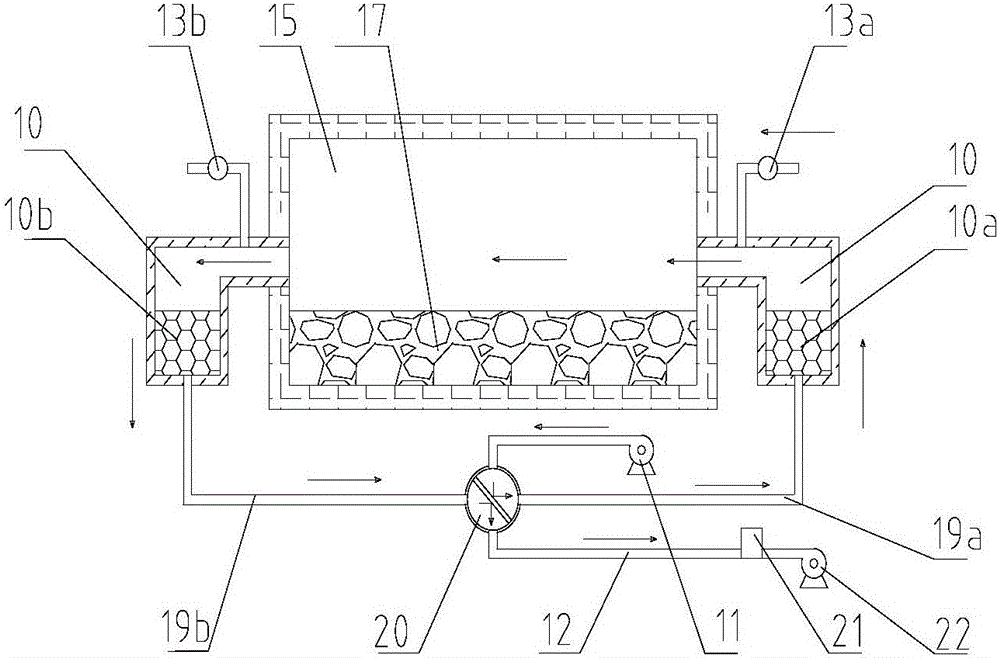

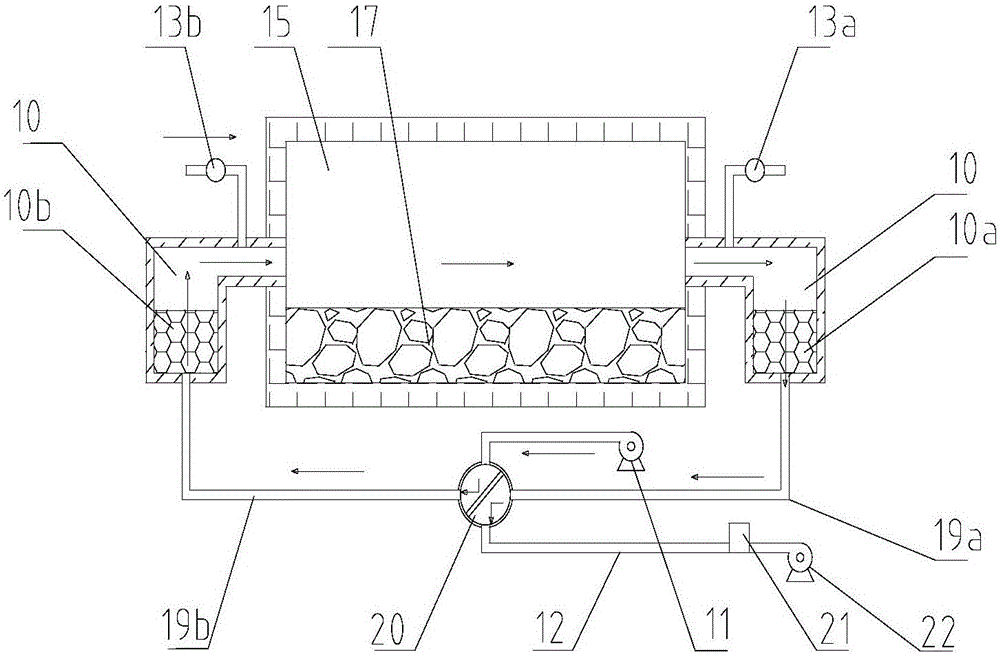

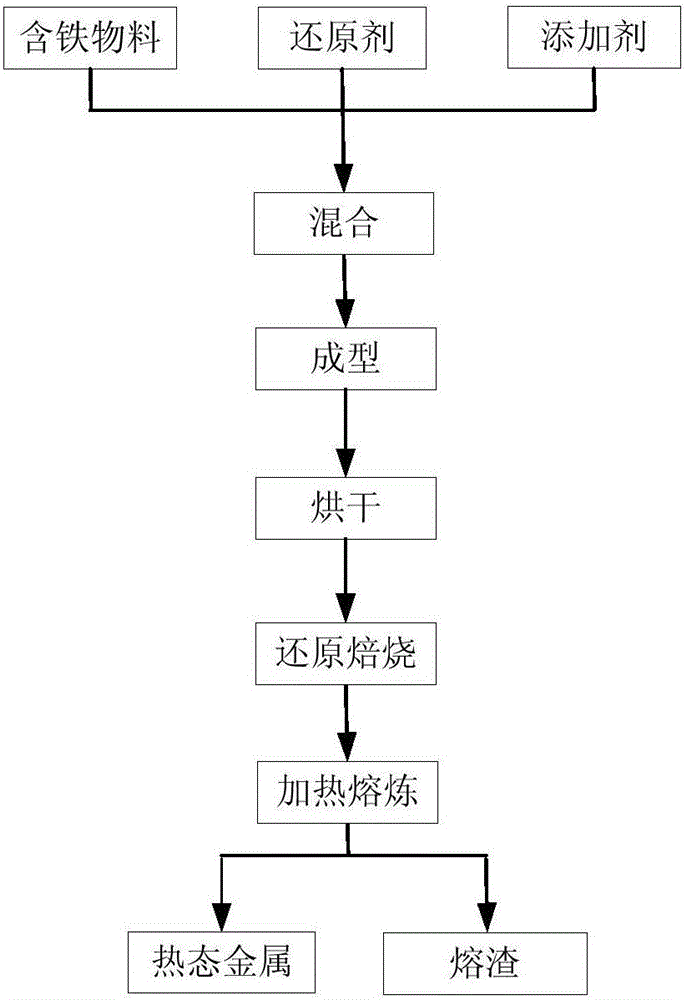

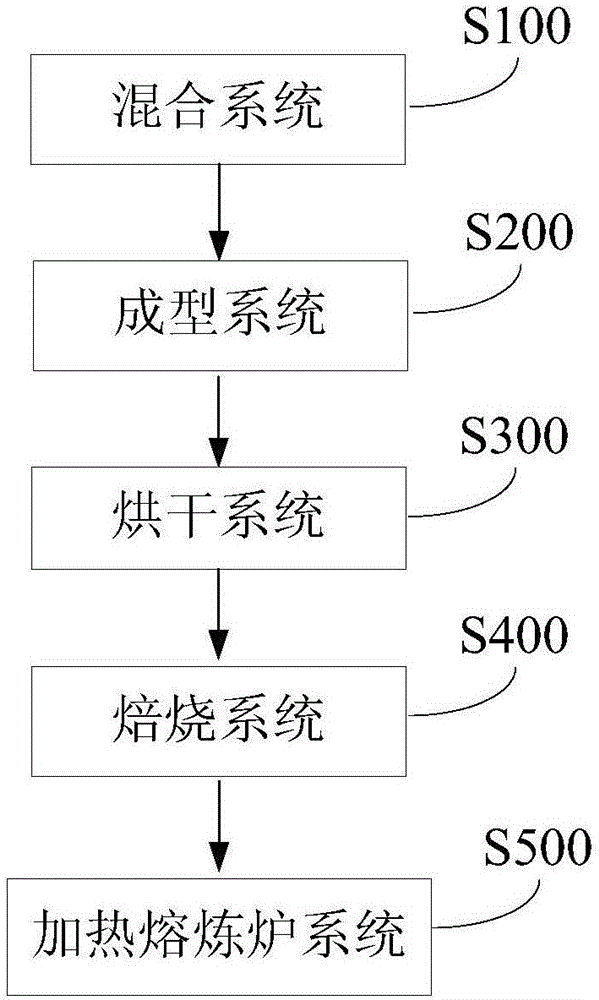

Iron-containing material treating system and application thereof to treatment of iron-containing materials

PendingCN106591528AWide applicabilityReduce smelting costProcess efficiency improvementSlagMagnetite

The invention discloses an iron-containing material treating system and an application thereof to treatment of iron-containing materials. The system comprises a mixing system, a forming system, a drying system, a roasting system and a heating and smelting furnace system, wherein a discharging hole of the mixing system communicates with a feeding hole of the forming system, a discharging hole of the forming system communicates with a feeding hole of the drying system, a discharging hole of the drying system communicates with a feeding hole of the roasting system, and a discharging hole of the roasting system communicates with a feeding hole of the heating and smelting furnace system. The system disclosed by the invention is suitable for treating iron-containing materials such as iron ores, laterite nickel ores, vanadium titano-magnetites, metallurgical dust and non-ferrous smelting slag and has the advantages of low smelting cost, environment friendliness, high product quality, wide raw material applicability, high recovery rate and the like.

Owner:JIANGSU PROVINCE METALLURGICAL DESIGN INST

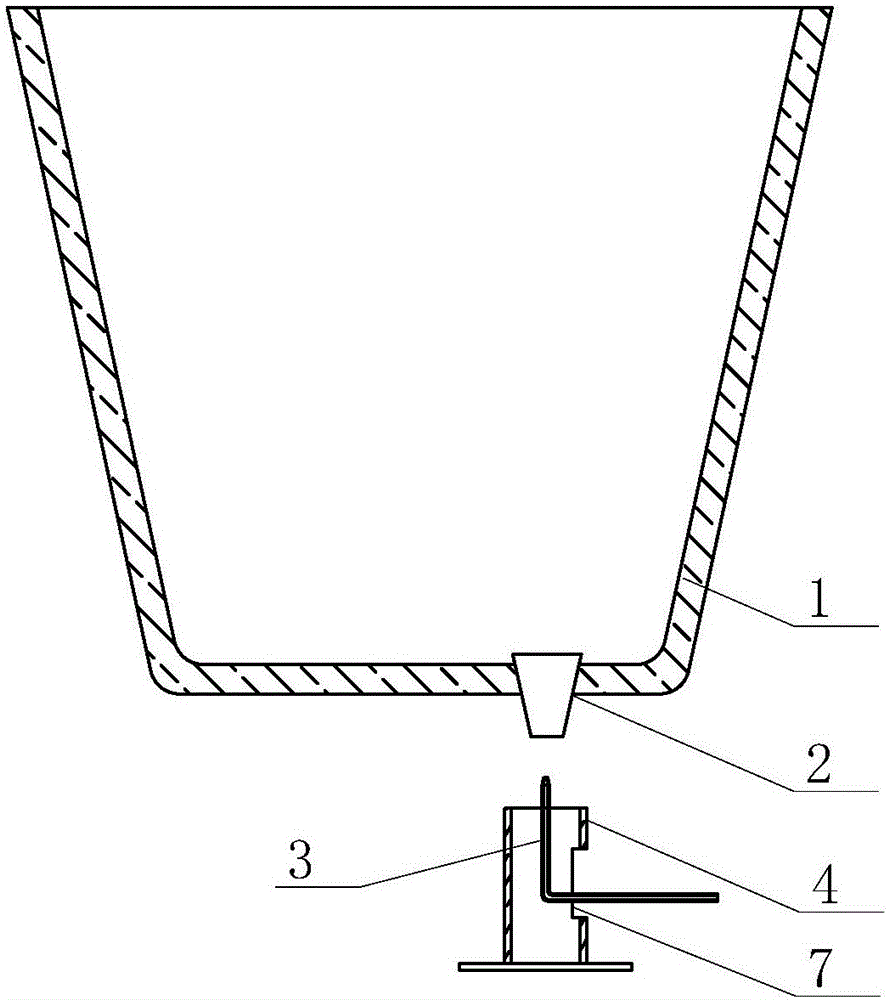

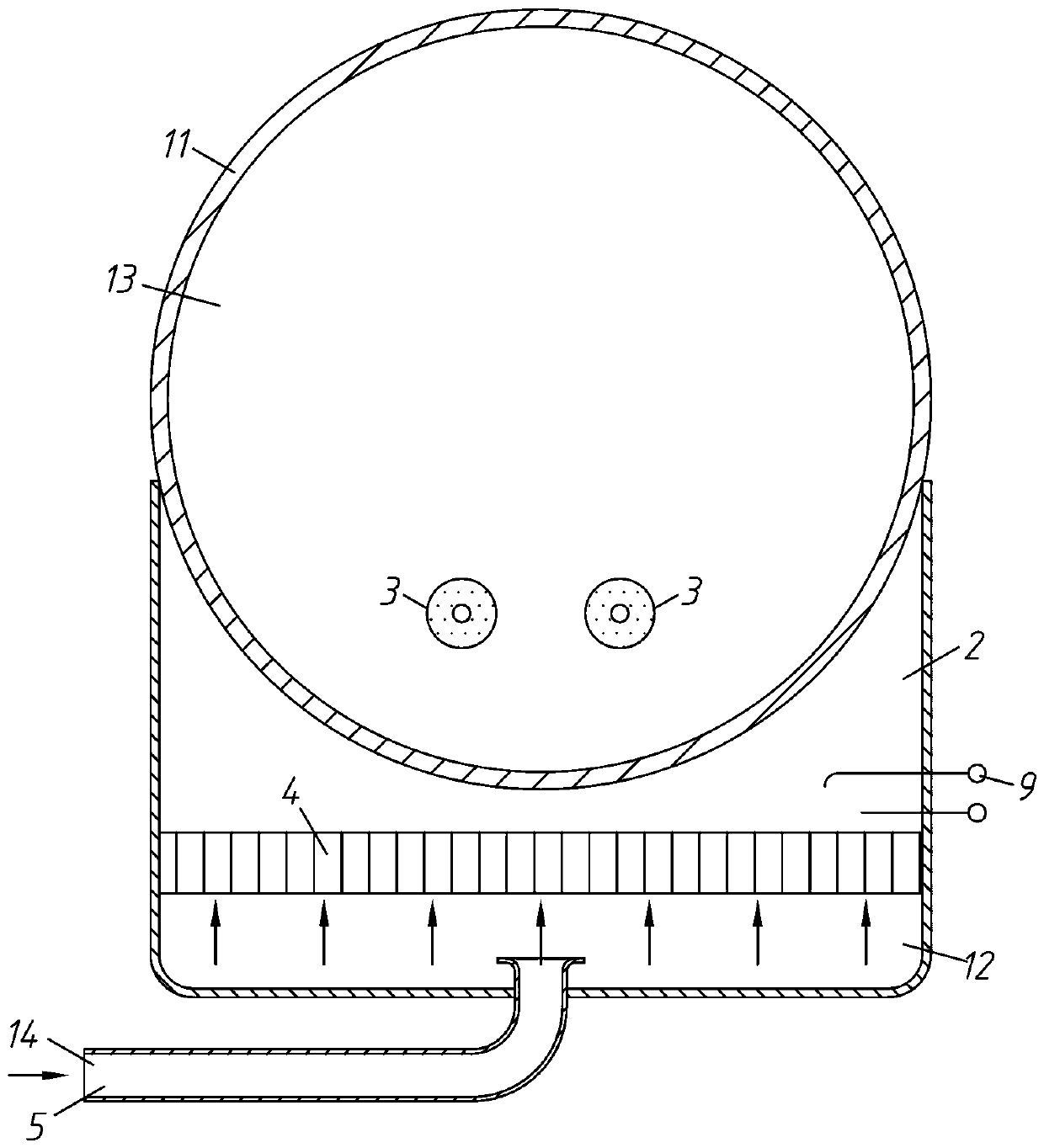

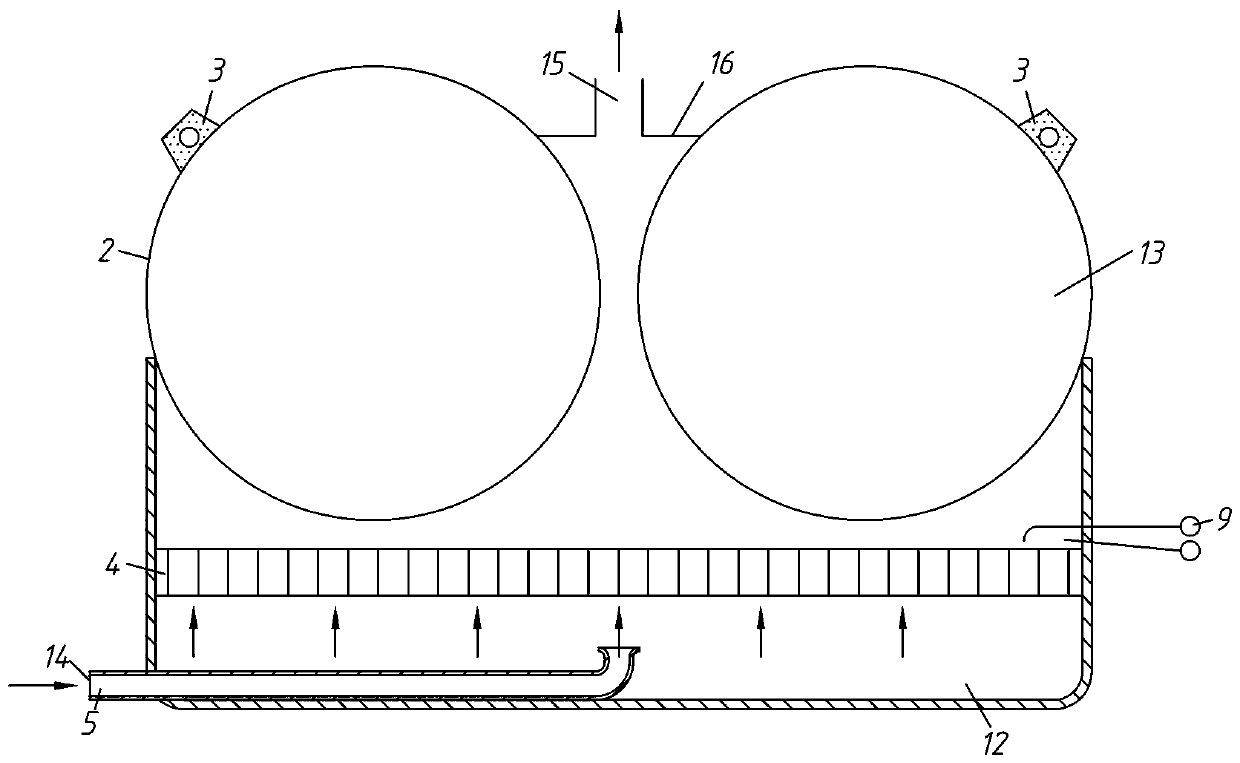

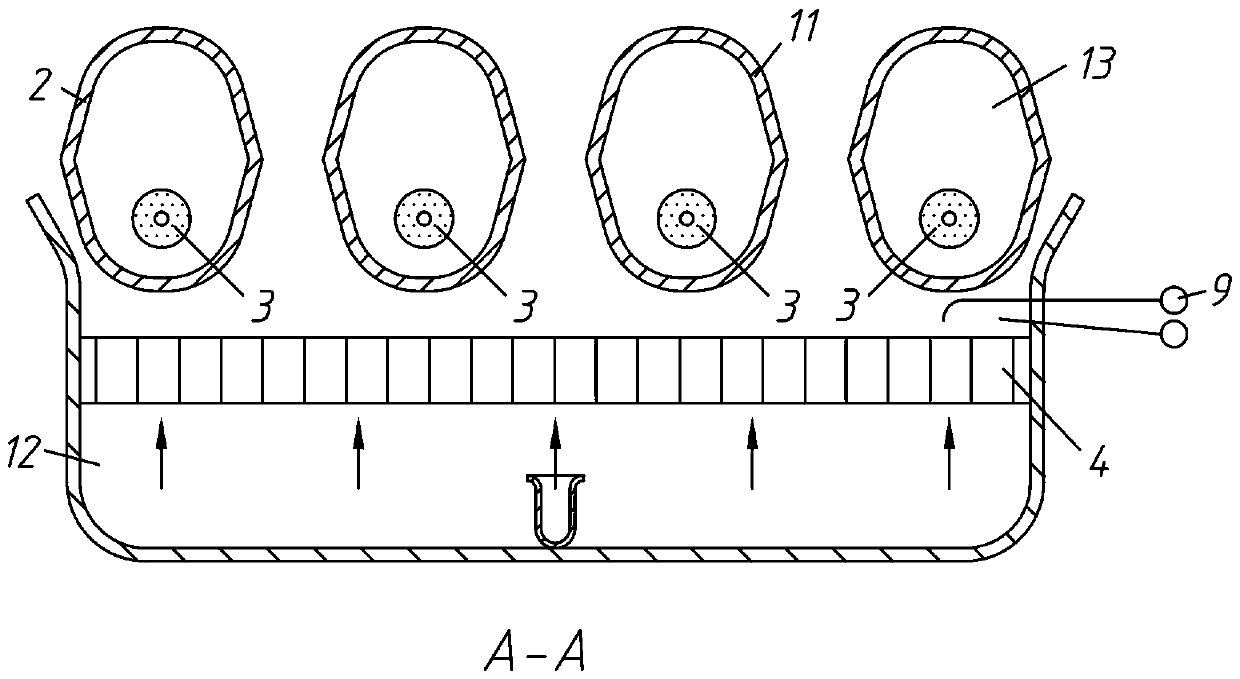

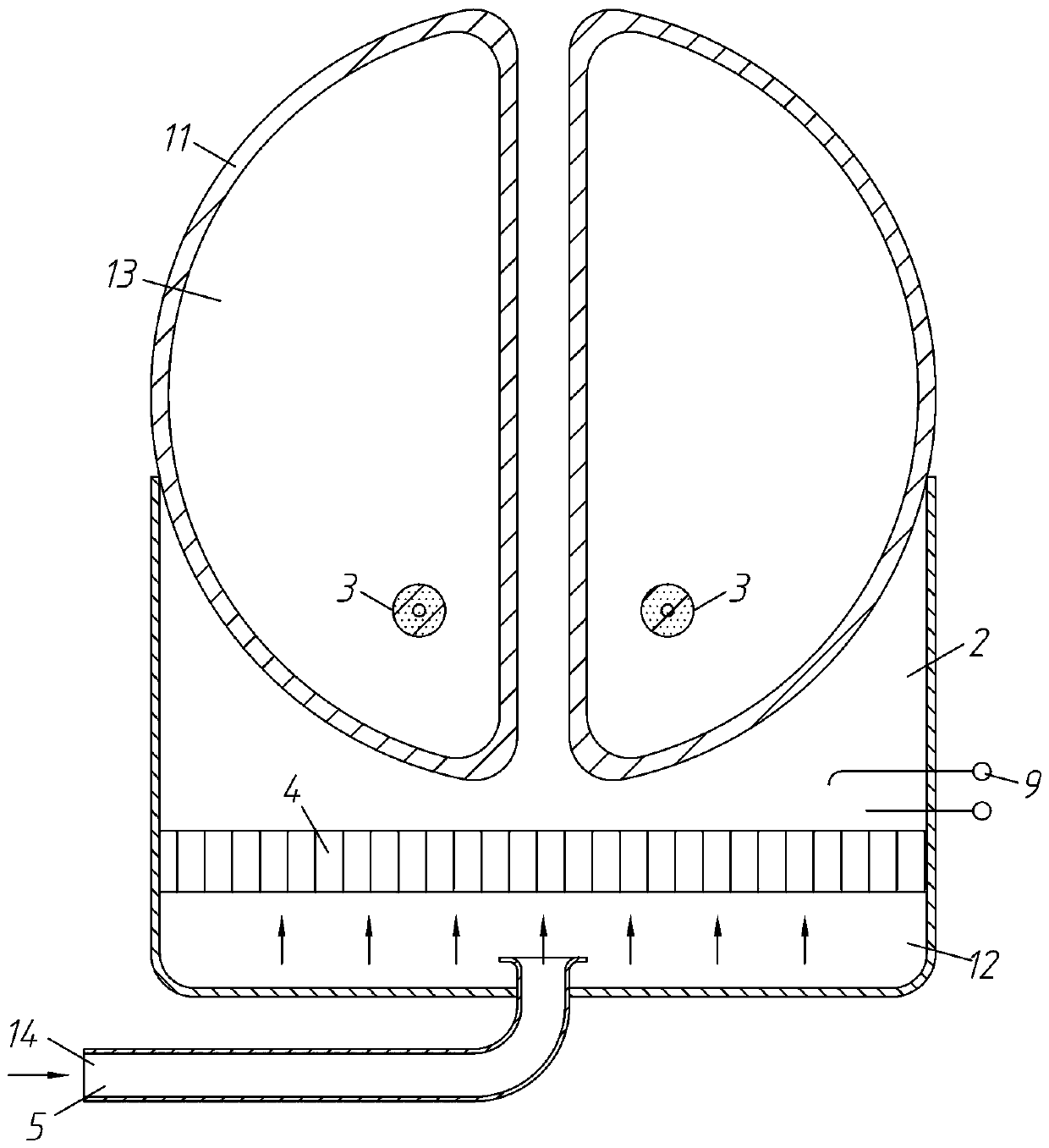

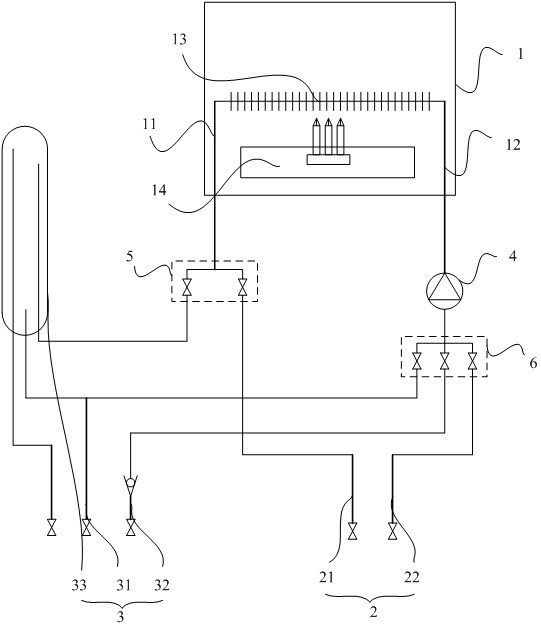

Bran steaming device

PendingCN109486579AReduce labor intensitySave gas consumptionAlcoholic beverage preparationEngineeringBran

The invention relates to the technical field of wine brewing and provides a bran steaming device. The bran steaming device comprises a material box and a breathable supporting seat arranged in the material box, wherein an inner cavity of the material box is divided into two parts by the breathable supporting seat, i.e., a bran steaming chamber positioned above the breathable supporting seat and asteam chamber positioned under the breathable supporting seat; the material box is provided with a feeding port communicated with the bran steaming chamber and an air inlet communicated with the steamchamber; the breathable supporting seat is a chain-plate conveying device; the position on the side wall of the material, corresponding to the discharging side of the chain-plate conveying device, isprovided with an unloading port; an unloading door which can be opened and closed is arranged at the position of the unloading port of the material box. The bran steaming device provided by the invention has the beneficial effects that automatic bran feeding, steaming and discharging can be realized, so that the labor intensity of workers is obviously reduced, the bran steaming efficiency is improved and the use amount of fuel gas is obviously reduced.

Owner:四川华宇瑞得科技有限公司

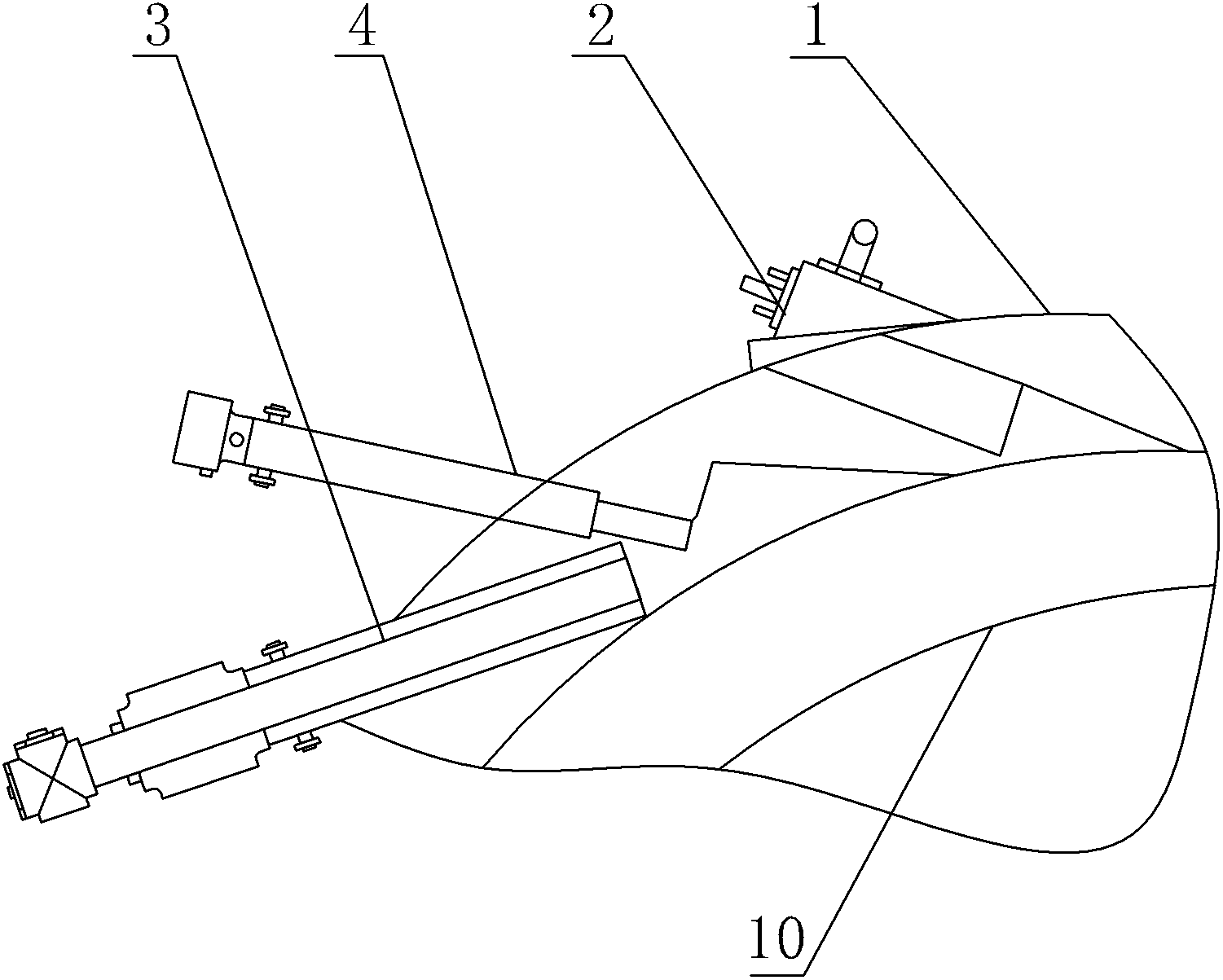

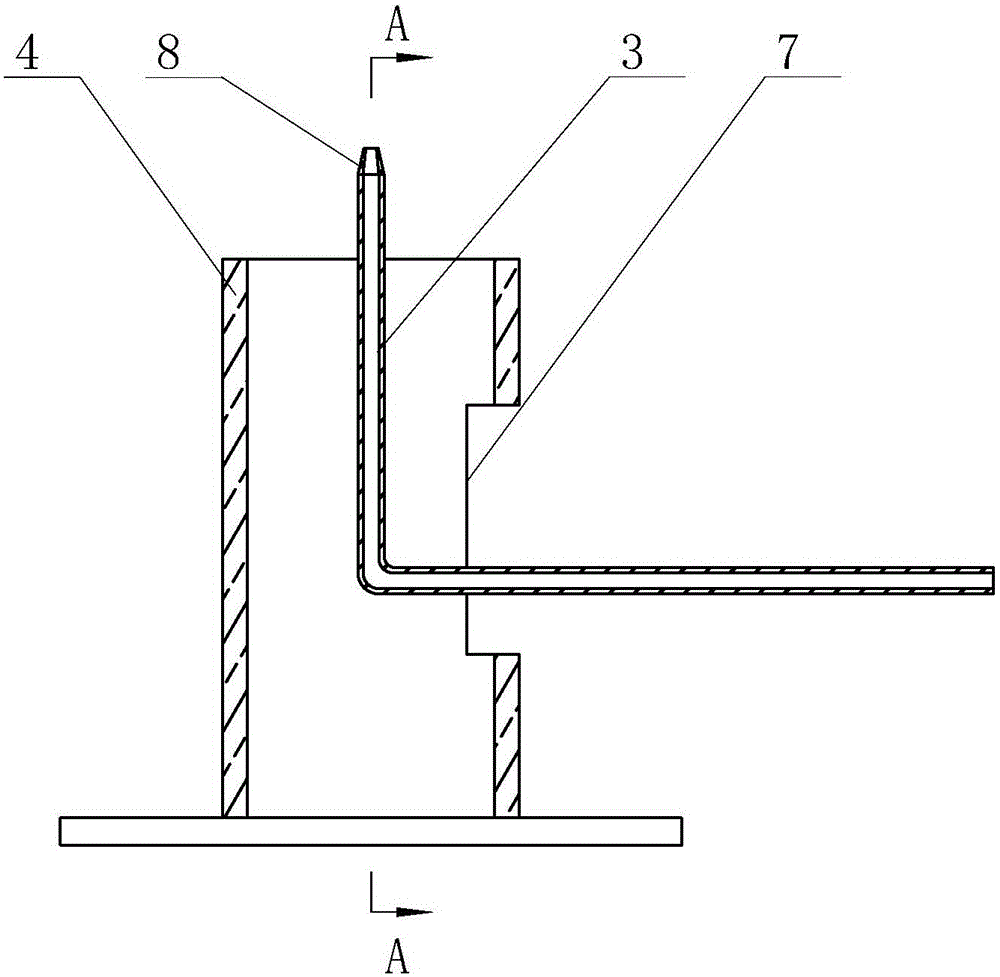

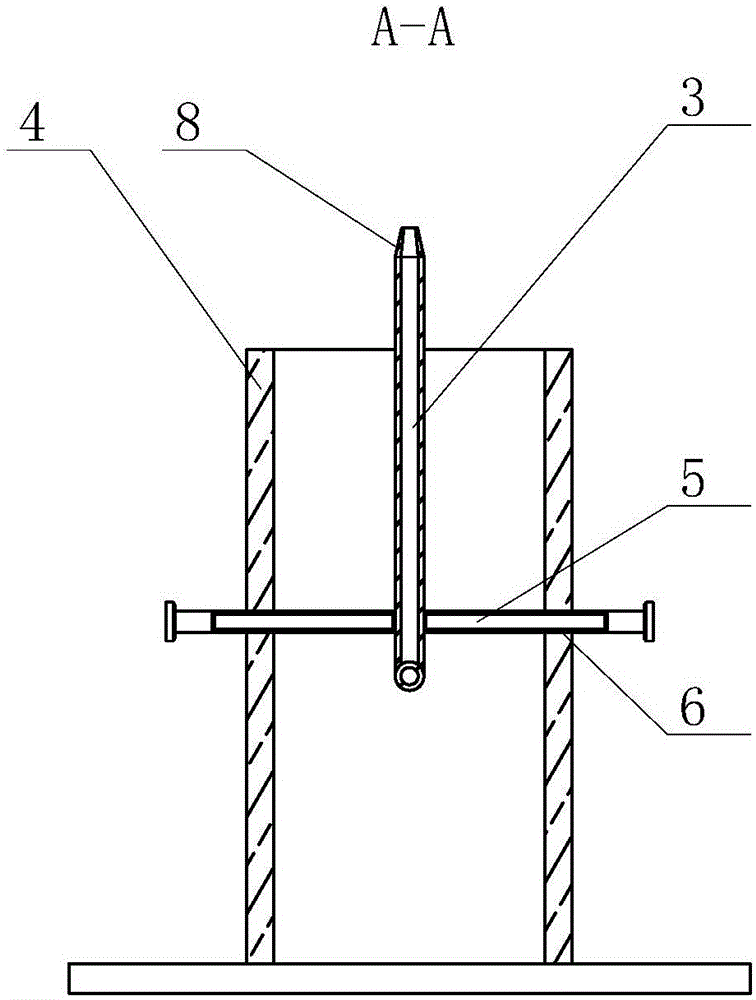

Fire clay blasting preventing baking method of steel ladle mechanism

InactiveCN105081303APrevent the danger of steel channelingEasy to fixMelt-holding vesselsMining engineeringCombustible gas

A fire clay blasting preventing baking method of a steel ladle mechanism comprises the steps that the cool state steel ladle mechanism with a replaced water gap and a replaced sliding plate is placed above an adjustable nozzle type baker, wherein the adjustable nozzle type baker comprises an outer cylinder, a gas pipe is arranged in the outer cylinder, and a gas pipe fixing and height adjusting mechanism is arranged on the side wall of the outer cylinder; the height of the gas pipe is adjusted, the combining face of the upper water gap and the upper sliding plate in the steel ladle mechanism is located in a nozzle combusting gas flame high-temperature area, and gas flowing out of a nozzle is ignited for baking; during baking, the combustible gas flow sequentially becomes high, low and high, and the gas supply time of the high-flow combustible gas is 2-3 times of the gas supply time of the low-flow combustible gas; and the total baking time is controlled within 30-60 min, an organic bonding agent and water in fire clay used for sealing of the sliding plate in the steel ladle mechanism are decomposed and volatilized step by step, and the fire clay is molded and stabilized. The organic bonding agent and the water in the fire clay used for sealing of the sliding plate can be decomposed and volatilized step by step, and the safety hazard of steel fleeing caused by instant fire clay blasting during molten steel casting on is avoided.

Owner:SHANDONG IRON & STEEL CO LTD

Roller kiln and smoke exhaust method of roller kiln based on furnace pressure control

PendingCN111089480ASimple structureLow costFurnace typesWaste heat treatmentProcess engineeringHearth

The invention discloses a roller kiln and a smoke exhaust method of the roller kiln based on furnace pressure control. The roller kiln comprises a furnace body with a hearth and a conveying device installed in the hearth. The hearth is provided with one or more smoke exhaust sections. The smoke exhaust sections are divided into a plurality of sub-sections which are sequentially connected in the conveying direction of the conveying device. Each sub-section is provided with a smoke exhaust device with the adjustable exhaust speed. The smoke exhaust method comprises the steps that an optimal smoke exhaust section with the smoke concentration is obtained, and the smoke exhaust devices are adjusted to enable the furnace pressure in the sub-section away from the optimal smoke exhaust section tobe smaller than the furnace pressure in the sub-section close to the optimal smoke exhaust section. The roller kiln and the smoke exhaust method have the advantages that the smoke exhaust efficiency can be improved, and energy consumption and gas consumption are reduced.

Owner:HUNAN JINLU TECH CO LTD

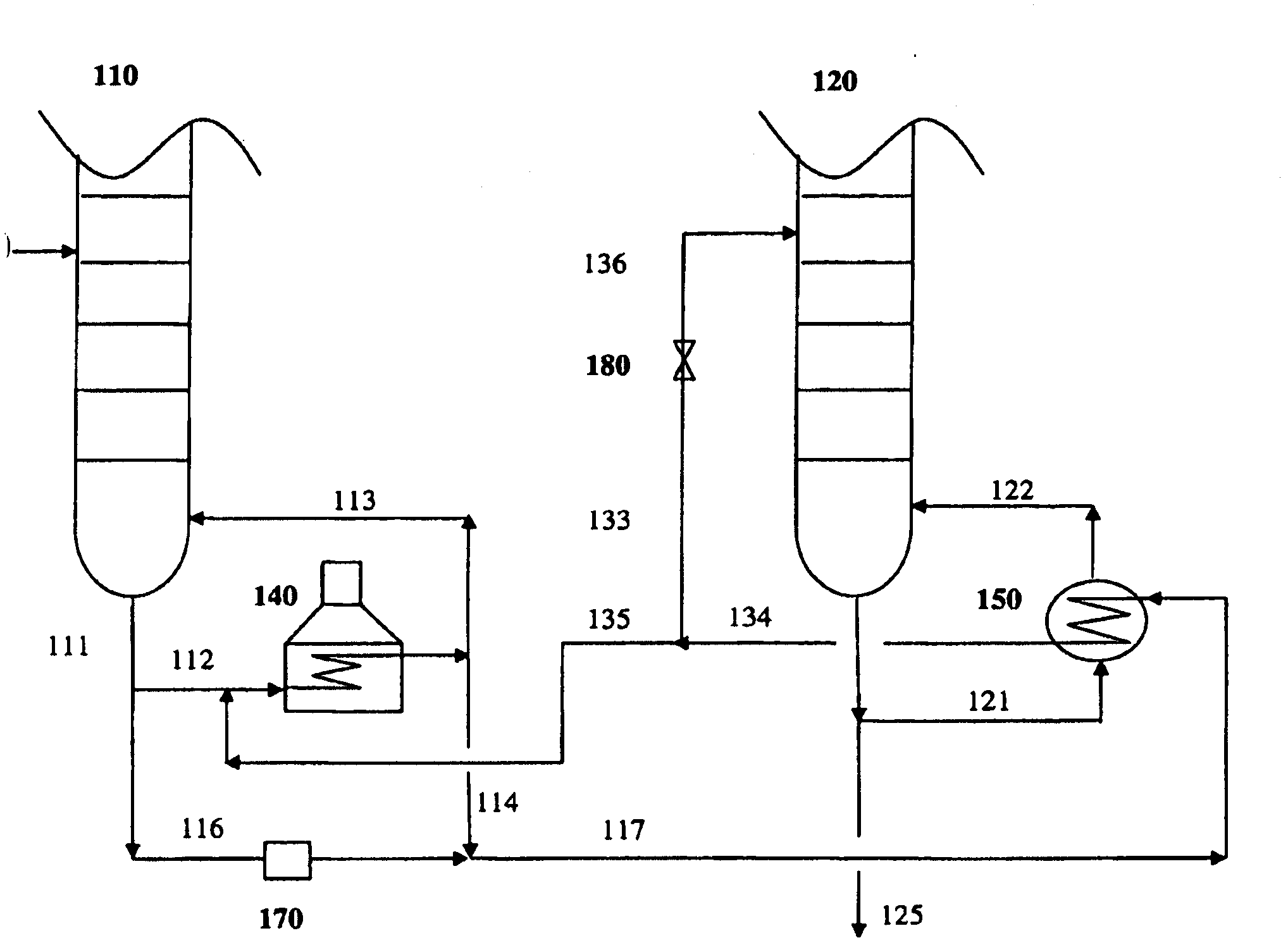

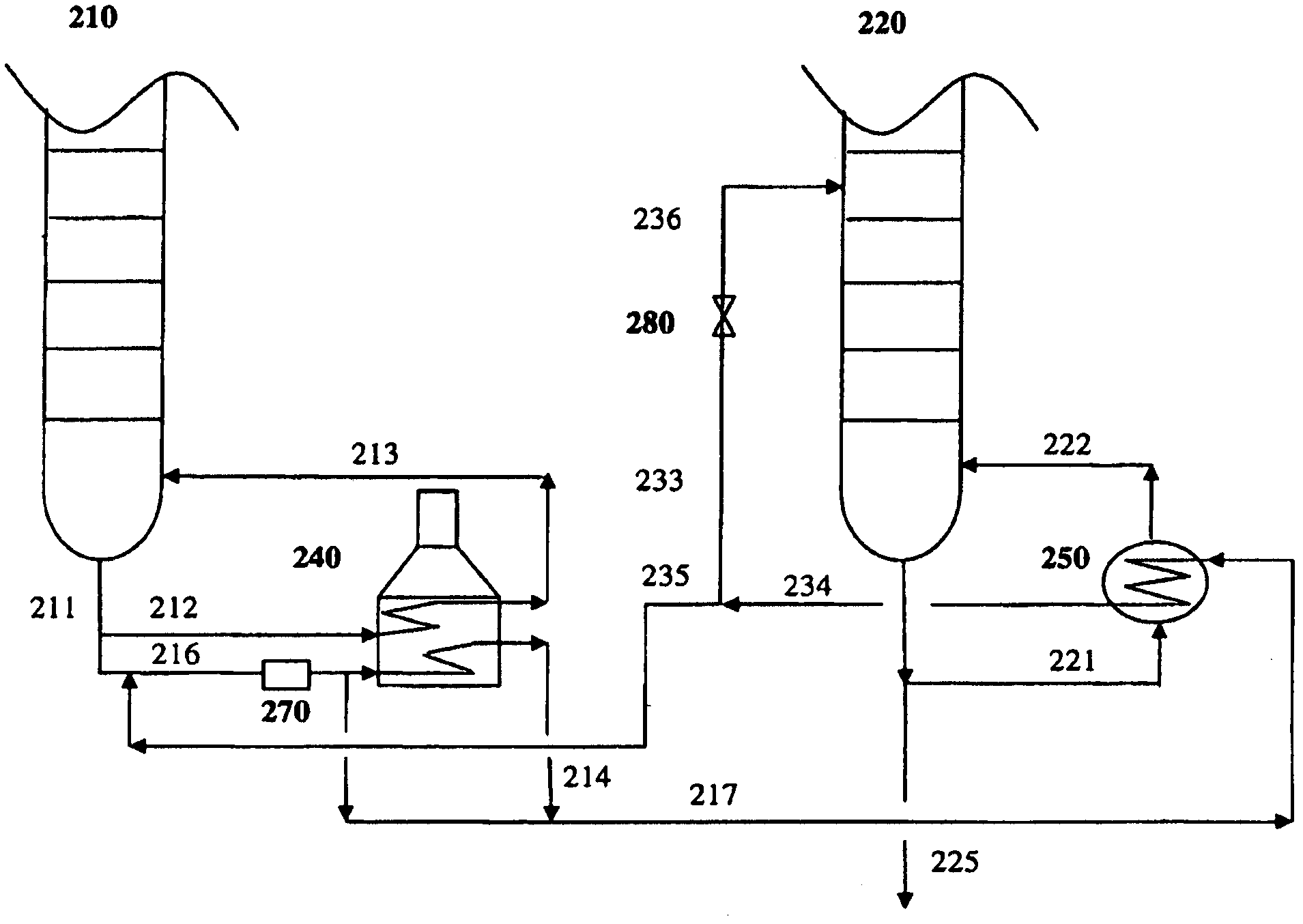

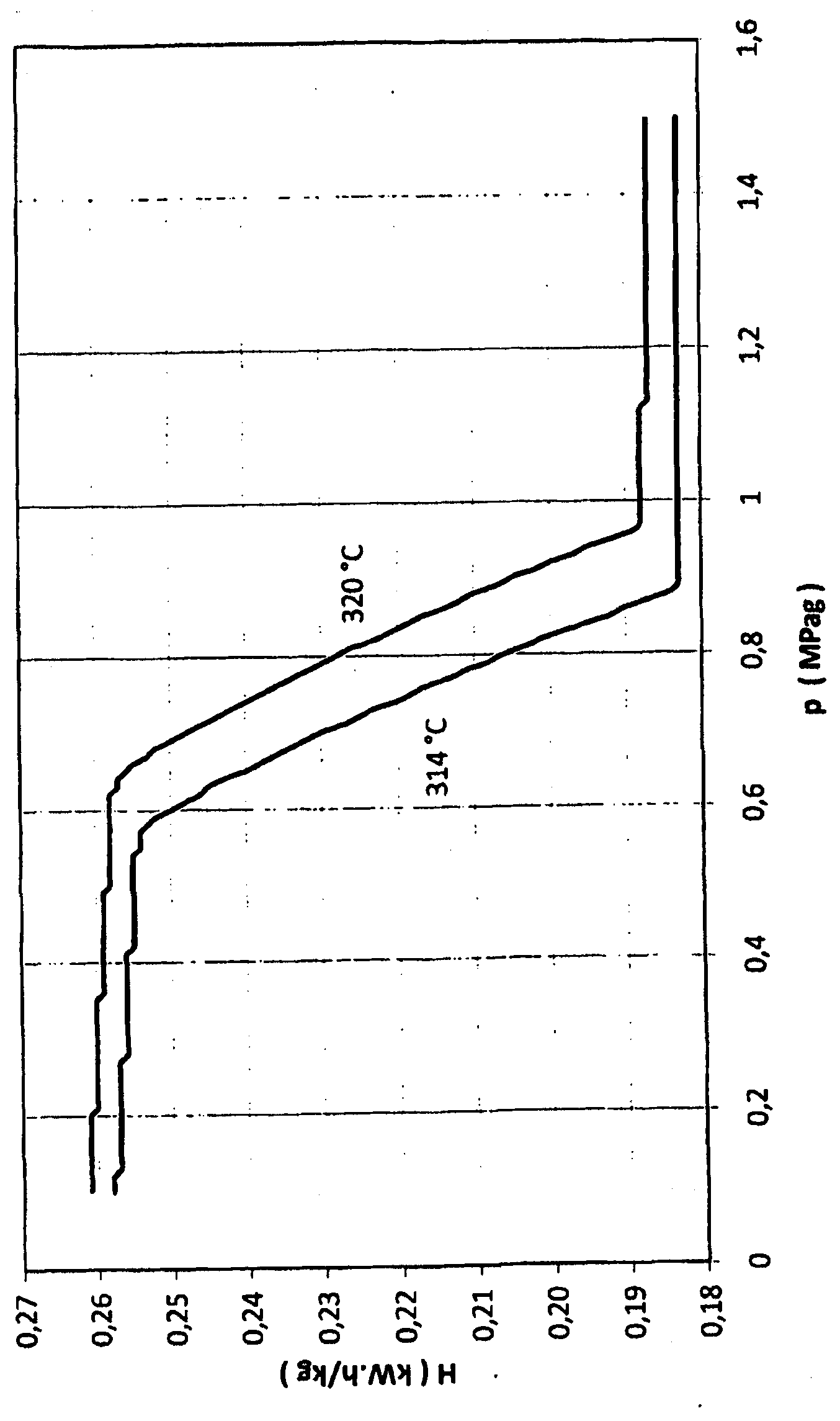

Distillation process and multi-column heat-integrated distillation system

InactiveCN102985145AReduce in quantityImprove energy efficiencyDistillation regulation/controlChemical industryReboilerDistillation method

The invention relates to a process for separating a multi-component feed mixture in a distillation system comprising a first distillation column having a first fired reboiler, and at least a second distillation column having a second heat-exchange reboiler, comprising the steps of a) introducing the feed mixture to the first column, and separating into at least a first top and a first bottom product; b) taking part of the first bottom product for providing heat to the second reboiler as a utility stream; and c) feeding part of said utility stream after heat-exchange as main feed to the second column for further separation. This process allows significant energy savings, by reduction of the amount of external heat required for the fired reboiler and omission of a conventionally used heat-exhanger. The invention also relates to such distillation system suitable for separating a multi-component mixture with the process of the invention.

Owner:SAUDI BASIC IND CORP SA

Multi-point injection gas supply system for fuel gas generator set

InactiveCN102444480ASave gas consumptionLow costInternal combustion piston enginesEngine controllersHazardous substanceOxygen sensor

The invention discloses a multi-point injection gas supply system for a fuel gas generator set. The multi-point injection gas supply system comprises a decompression valve, a fuel gas injection track, a cylinder, a gas inlet manifold and a gas outlet manifold, wherein the gas outlet manifold is provided with an oxygen sensor; and both the oxygen sensor and the fuel gas spray track are connected with a signal processing and controlling device. In the invention, the practically-required air-fuel ratio is optimized automatically by using the signal processing and controlling device, the startup time of the fuel gas injection track is adjusted automatically according to a signal detected by the oxygen sensor, and the air-fuel ratio practically required by the cylinder of the generator set is optimized, so that the quantity of harmful substances emitted by tail gas are controlled at the minimum value, energy is saved, and contribution to environmental protection is made simultaneously.

Owner:崔敏娟

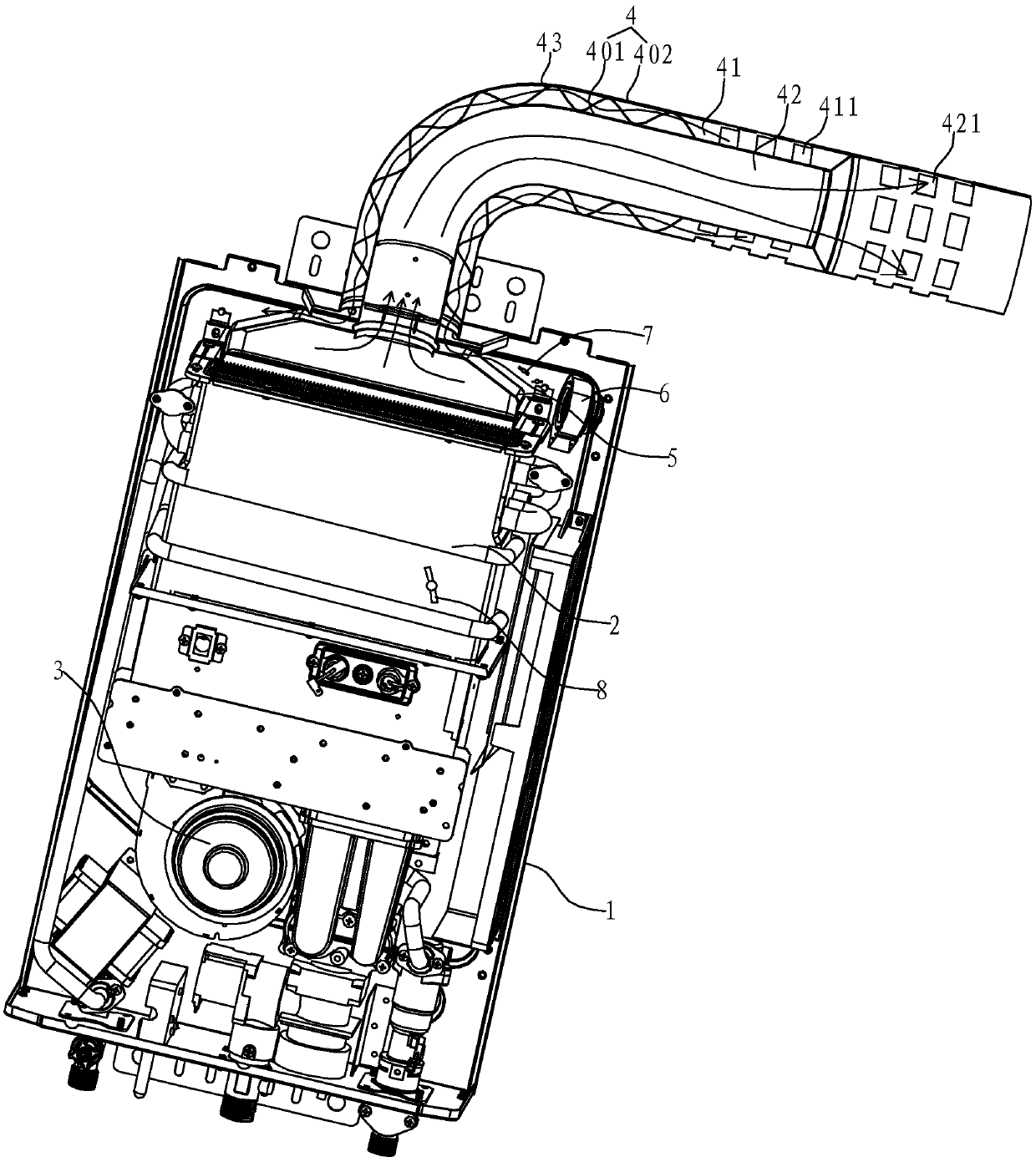

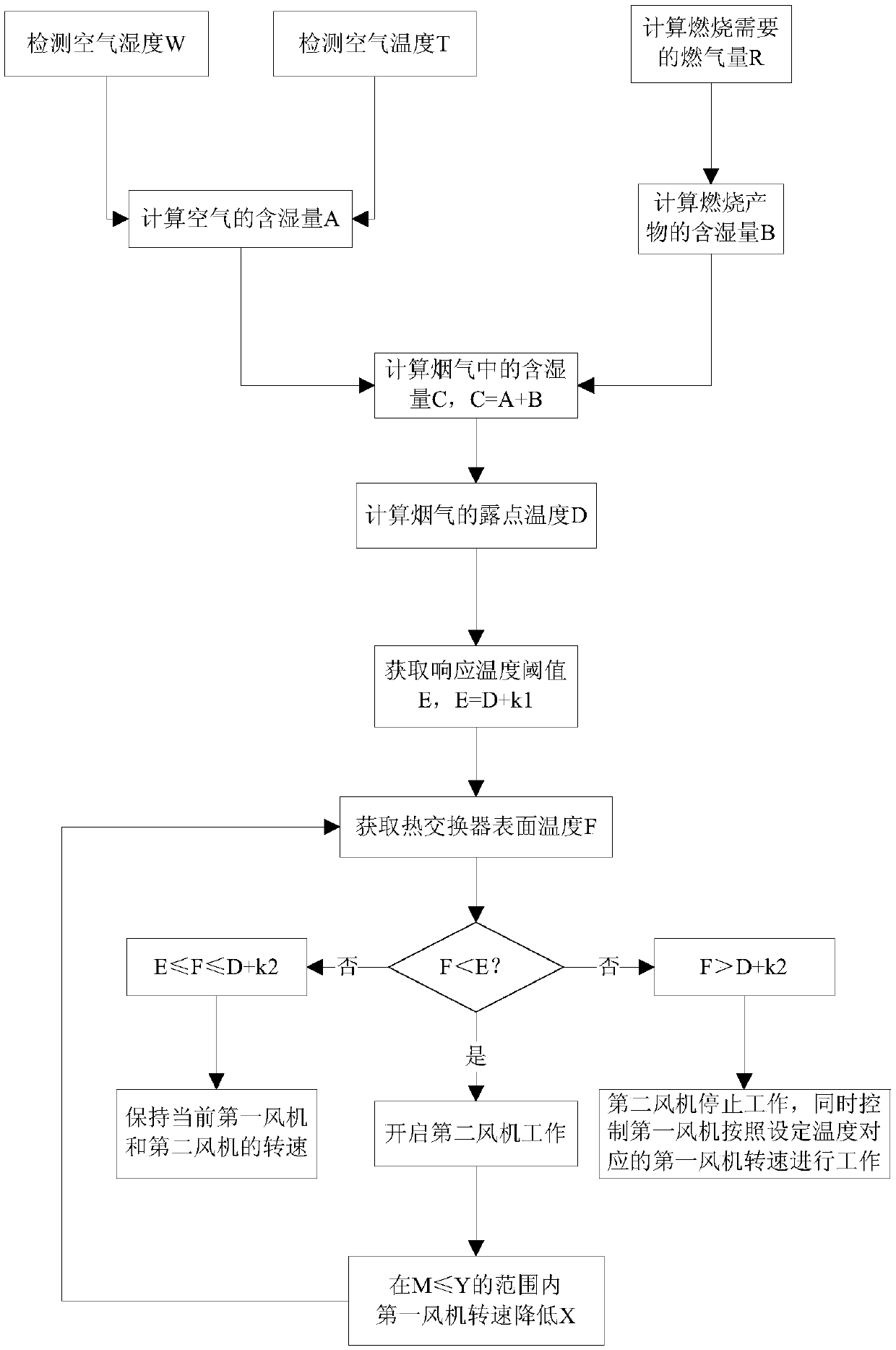

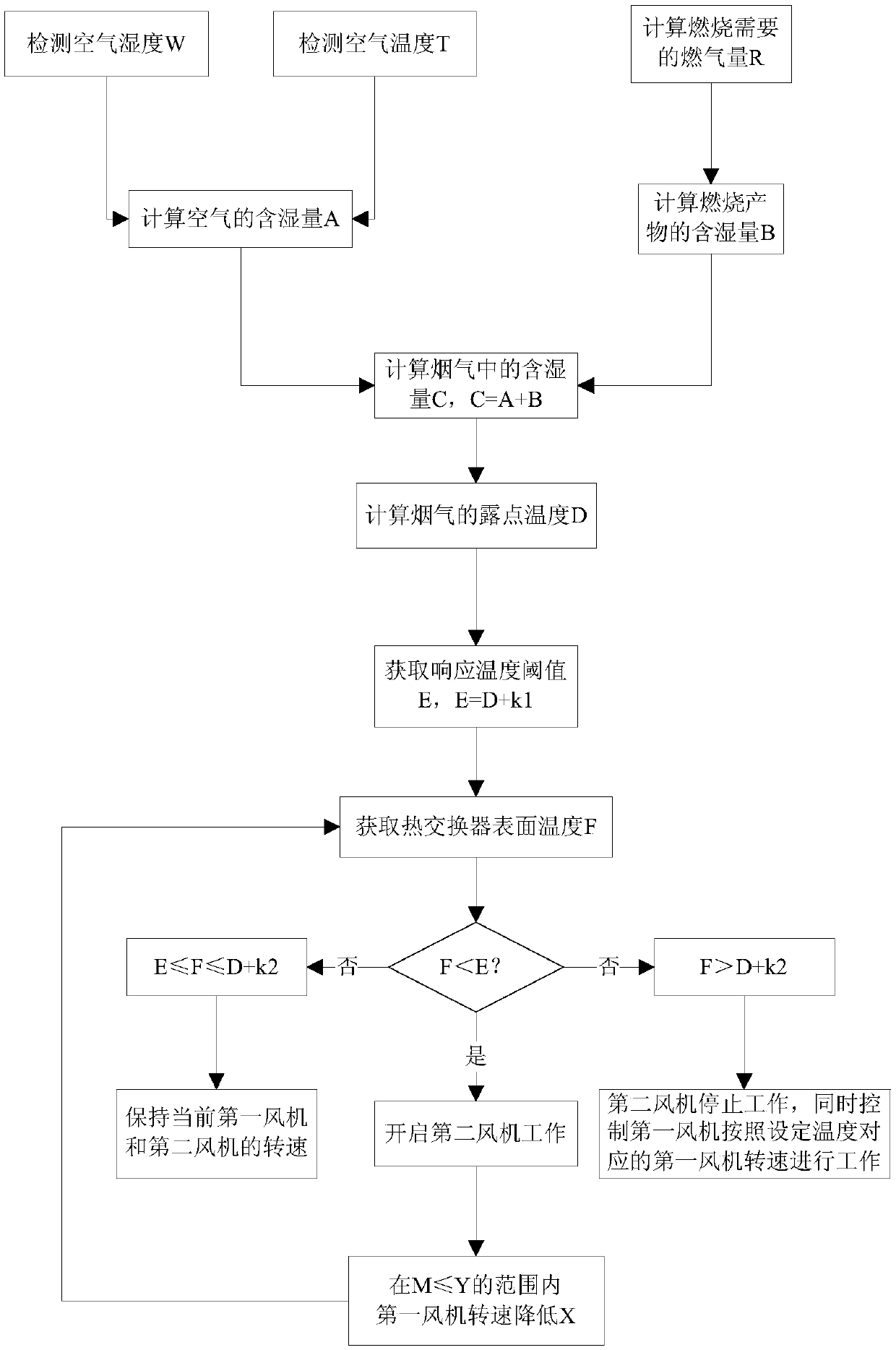

Condensate water prevention gas water heater and control method

ActiveCN111121276AAvoid Threshold ConstantsWill not precipitateWater heatersCombustion chamberEngineering

The invention relates to a condensate water prevention gas water heater. The condensate water prevention gas water heater comprises a shell, a heat exchanger, a first draught fan, a vent pipe, a second draught fan, a temperature and humidity sensor and a temperature sensor, wherein the first draught fan is arranged at an air inlet of a combustion chamber; the second draught fan and the temperatureand humidity sensor are arranged close to an outlet of an air inlet pipe; the temperature sensor is arranged on the surface of the heat exchanger; the vent pipe comprises the air inlet pipe and a smoke exhaust pipe which are isolated; and a spiral blocking plate is arranged in the air inlet pipe. The invention further relates to a control method of preventing condensate water of the gas water heater. The control method comprises the steps of calculating the moisture content of air going into the shell, and calculating the moisture content of combustion products; calculating the moisture content of exhaust gas according to the moisture content of the air and the moisture content of the combustion products; calculating the dew point temperature of the exhaust gas according to the moisture content of the exhaust gas; and comparing the dew point temperature of the exhaust gas with the surface temperature of the heat exchanger, adjusting the rotating speeds of the second draught fan and the first draught fan according to the comparison result and then reducing the moisture content of the air going into the shell. Through the condensate water prevention gas water heater and the controlmethod, the dew point temperature of the exhaust gas can be reduced, and generation of condensate water is prevented.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

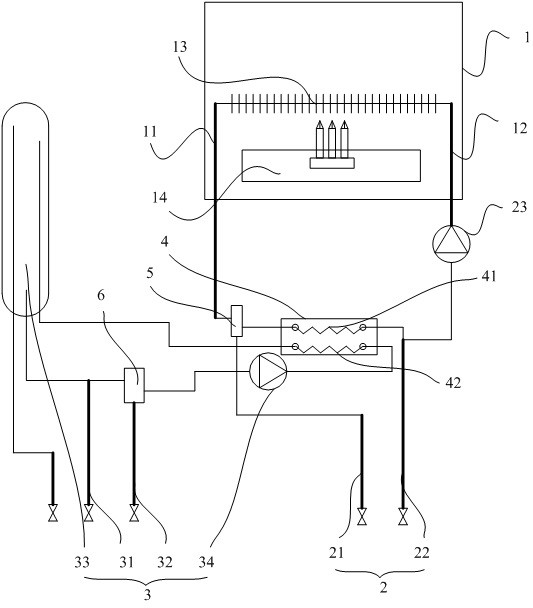

Gas heating equipment and heating hot water supply system

PendingCN112032999AReduce switching timesImprove experienceMechanical apparatusWater heatersWater useEngineering

The invention discloses gas heating equipment and a heating hot water supply system. The gas heating equipment is characterized in that a main water outlet and a main water inlet are arranged on gas furnace, a heating water outlet pipe and a heating water return pipe are arranged on a heating assembly, a cold water inlet pipe, a zero-cold water return pipe, a water tank and a water pump are arranged on a hot water supply assembly, a hot water outlet and a circulating water inlet are arranged on the water tank, a first heat exchange flow channel and a second heat exchange flow channel which canexchange heat with each other are arranged on a heat exchanger, the main water outlet is connected with the heating water outlet pipe and the first heat exchange flow channel through a first reversing valve, the heating water return pipe and the first heat exchange flow channel are connected with the main water inlet, the second heat exchange flow channel is connected with the cold water inlet pipe and the zero-cold water return pipe through the second reversing valve, and the second heat exchange flow channel is connected with the circulating water inlet. Water stored in an external water pipe is heated or buffered through the water tank, so that the starting and stopping frequency of the gas furnace is reduced, the fluctuation of the water outlet temperature is reduced, the gas consumption is reduced, and the water use experience of a user is improved.

Owner:QINGDAO ECONOMIC & TECHN DEV ZONE HAIER WATER HEATER +1

Infrared gas heating or infrared gas and electric heating water heater

The invention discloses an infrared gas heating or infrared gas and electric heating water heater. According to the infrared gas heating or infrared gas and electric heating water heater, infrared gascombustion is adopted to replace atmospheric direct injection combustion, one or more infrared burners are arranged in a shell 1, each infrared burner is composed of a heat exchange water container,a metal or non-metal ceramic honeycomb plate, a fuel gas primary complete mixing chamber, an ignition needle and a flameout protection device, wherein one or more electric heating tubes are arranged outside or inside the heat exchange water container, the metal or non-metal ceramic honeycomb plate is below the heat exchange water container, the lower part of the honeycomb plate is a fuel gas-air mixed space, and mixing of fuel gas and air is primary complete mixing.

Owner:广东顺德八米科技有限公司

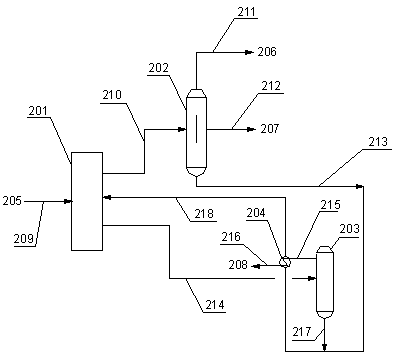

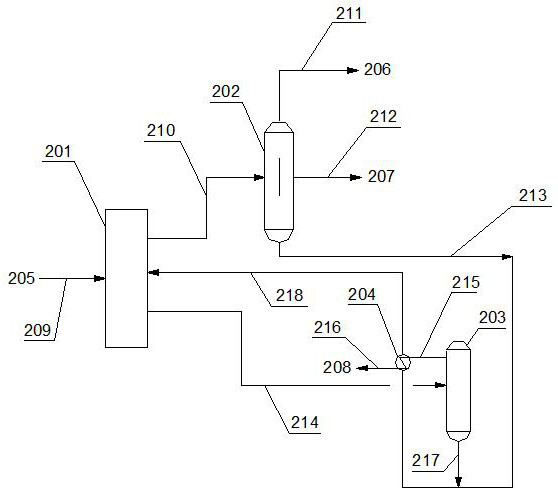

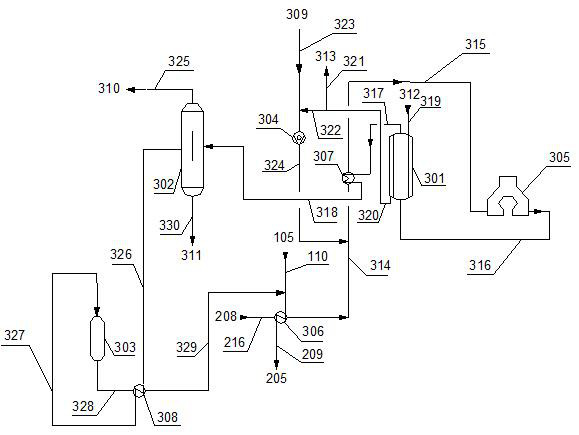

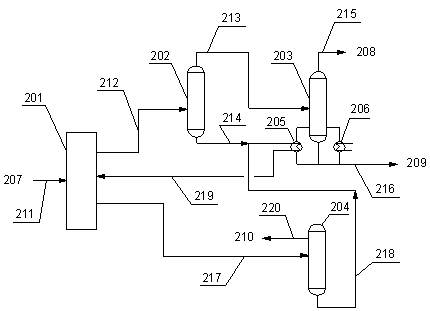

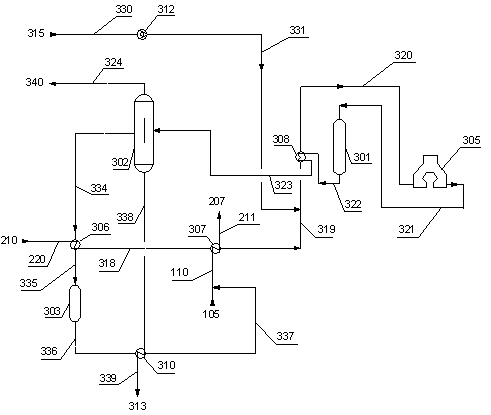

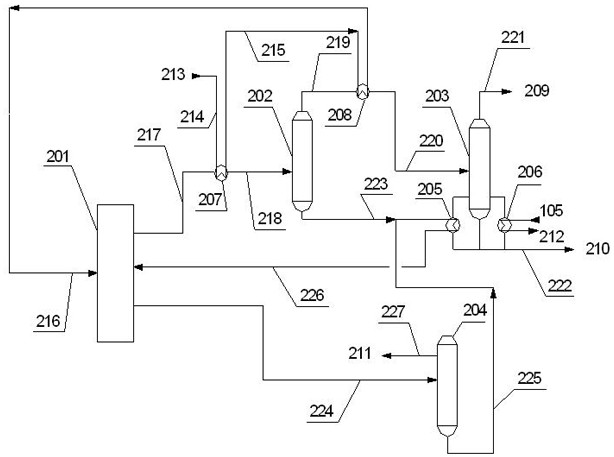

Device and process for producing p-xylene

ActiveCN110937969AReduce operating loadSave gas consumptionHydrocarbon by isomerisationChemical industryChemistryReboiler

The invention discloses a device and a process for producing p-xylene. The device comprises a xylene fractionation unit, an adsorption separation unit and an isomerization reaction unit, wherein the adsorption separation unit comprises an adsorption separation tower, an extraction liquid fractionating tower, a raffinate tower and a heat exchanger II, and the isomerization reaction unit comprises an isomerization reactor, an isomerization product fractionating tower, a white clay tower, an isomerization reaction heating furnace, a heat exchanger III, a heat exchanger IV, a heat exchanger V anda compressor. The invention also provides a process for producing p-xylene. According to the invention, with the device and the process, the equipment investment and the occupied area are reduced, theoperation load of the xylene tower is reduced, the fuel gas consumption of the xylene reboiler and the isomerization reaction heating furnace is saved, the heat exchange network is optimized, the energy consumption is greatly reduced, and the economic benefit and the social benefit are improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method of dimethyl ether gas nono rare earth combustion improver

The invention relates to a preparation method of a dimethyl ether gas nono rare earth combustion improver, comprising the following steps: preparing lanthanum neodymium chloride mixed solution to obtain mixed solution A; preparing ammonia water, and adding the prepared ammonia water into the mixture A to stir and obtain semitransparent mixture B; putting mixture B into a hydrothermal reaction kettle to perform hydrothermal reaction and obtain lanthanum neodymium oxide nano seed crystal C; detecting particle size of the lanthanum neodymium oxide nano seed crystal as 5-8 nm through a transmission electron microscope; preparing cerium chloride solution, taking ethylene glycol as micro emulsion carrier, adding the cerium chloride solution into the ethylene glycol, and stirring to obtain mixed solution D; adding seed crystal C into solution D, heating and stirring to obtain the dimethyl ether gas nono rare earth combustion improver. According to the preparation of the dimethyl ether gas nono rare earth combustion improver provided by the invention, cost is low; the method is suitable for industrial production; technologies are simple; the dimethyl ether gas combustion improver prepared by the method has high combustion efficiency; and dimethyl ether is gasified fully.

Owner:CHANGZHOU GEOQUIN NANO NEW MATERIALS

Infrared gas heating or infrared gas heating and electric heating combined module furnace

The invention discloses an infrared gas heating or infrared gas heating and electric heating combined module furnace. Infrared gas combustion is adopted to replace atmosphere direct injection combustion, one or more infrared burners are arranged in a shell 1, each infrared burner is composed of a heat exchange water container, a metal or non-metal ceramic honeycomb plate, a gas mixing chamber, anignition needle and a flameout protection device, one or more groups of electric heating tubes are arranged inside each heat exchange water container, the honeycomb plates made of metal or non-metal ceramic are located below the electric heating tubes, and the gas and air mixing chambers are arranged under the honeycomb plates, and are used for one-step complete mixing; domestic hot water and heating hot water are correspondingly supplied through different water tanks, and the heating hot water is realized through secondary heating.

Owner:广东顺德八米科技有限公司

Gas heating device and heating hot water supply system

ActiveCN112032996AReduce switching timesImprove experienceWater heatersSustainable buildingsWater useGas heating

The invention discloses a gas heating device and a heating hot water supply system. The gas heating device comprises a gas furnace, a heating assembly, a hot water supply assembly, a water outlet switching valve, a water inlet switching valve and a circulating pump, wherein the gas furnace is provided with a main water outlet and a main water inlet, and the gas furnace is used for combusting gas to heat water input from the main water inlet and outputting hot water from the main water outlet; the heating assembly is provided with a heating water outlet pipe and a heating water return pipe; thehot water supply assembly is provided with a cold water inlet pipe, a zero-cold water return pipe, a water tank and a water pump, and the water tank is provided with a hot water outlet and a circulating water inlet; the water outlet switching valve is used for correspondingly connecting the circulating water inlet and the heating water outlet pipe with the main water outlet; the water inlet switching valve is used for correspondingly connecting the cold water inlet pipe, the zero-cold water return pipe and the heating water return pipe with the main water inlet; and the circulating pump is connected between the water inlet switching valve and the main water inlet. Water stored in an external water pipe is heated or buffered through the water tank, so that the starting and stopping frequency of the gas furnace is reduced, the fluctuation of the water outlet temperature is reduced, the gas consumption is reduced, and the water use experience of a user is improved.

Owner:QINGDAO ECONOMIC & TECHN DEV ZONE HAIER WATER HEATER +1

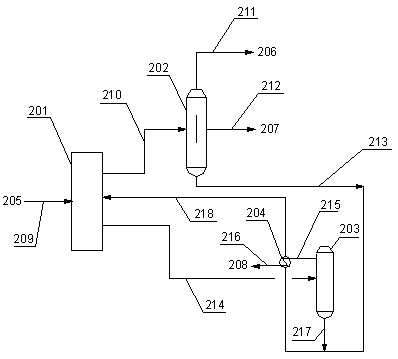

Production device and process of aromatic hydrocarbon product

ActiveCN112441870AReduce backmixingReduce irrational useChemical industryDistillation purification/separationXylyleneSocial benefits

The invention discloses a production device and process of an aromatic hydrocarbon product. The device comprises a xylene fractionation unit, an adsorption separation unit and an isomerization reaction unit; the adsorption separation unit comprises an adsorption separation tower, an extract fractionating tower, a raffinate tower and a heat exchanger II; and the isomerization reaction unit comprises an isomerization membrane reactor, an isomerization product fractionating tower, a carclazyte tower, an isomerization reaction heating furnace, a heat exchanger III, a heat exchanger IV, a heat exchanger V and a compressor. The invention also provides a production process of the aromatic hydrocarbon product. According to the invention, the equipment investment is reduced, the operation load of the xylene tower is reduced, the fuel gas consumption of the xylene reboiler is saved, the phenomenon of unreasonable energy consumption of cooling and then heating materials is avoided, meanwhile, theheat exchange network is optimized, the fuel gas consumption of the isomerization reaction heating furnace is reduced, the energy consumption is greatly reduced, and the economic benefit and the social benefit are improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Waste hydrogen combustion system for full-hydrogen bell-type furnace used for bright annealing

InactiveCN102206742BImprove heat transfer efficiencyAvoid damageFurnace typesHeat treatment furnacesCombustion chamberThermodynamics

Owner:艾伯纳工业炉(太仓)有限公司

Manufacturing method of hydrogen oxygen generator of combustion machine

InactiveCN108796336ANo emissionsEmission reductionFoundry mouldsHydrogen productionCombustionHydrogen

The invention discloses a manufacturing method of a hydrogen oxygen generator of a combustion machine. The technical problems that natural gas source is strained and the pollution discharge amount islarge are solved. The manufacturing method comprises the following steps of 1, 10-60 parts by weight of nickel and 20-80 parts by weight of lanthanum oxide are added and melted, and then 10-50 parts by weight of titanium are melted; and 2, the nickel, the lanthanum oxide and the titanium after melting are uniformly poured into a mould, and the hydrogen oxygen generator is formed. According to themanufacturing method, the gas source strain caused after coal modification is relieved, and the pollution discharge is greatly reduced.

Owner:HEBI BAOFA ENERGY SCI & TECH

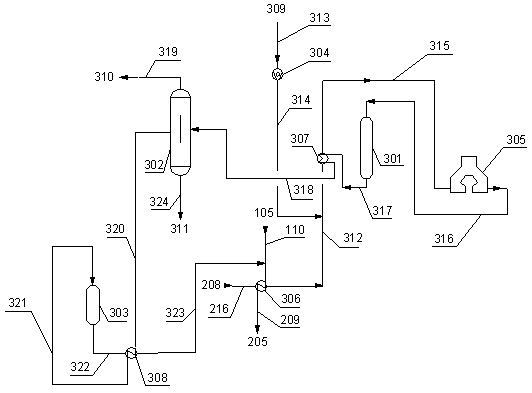

Production device and production process of p-xylene

ActiveCN110937974AIncreased operating loadReduce operating loadHydrocarbon by isomerisationChemical industryXylyleneSocial benefits

The invention discloses a production device and a production process of p-xylene. The device comprises a xylene fractionation unit, an adsorption separation unit and an isomerization reaction unit, wherein the adsorption separation unit comprises an adsorption separation tower, an extraction liquid tower, a raffinate tower, a finished product tower, a finished product tower reboiler I and a finished product tower reboiler II, and the isomerization reaction unit comprises an isomerization reactor, an isomerization product fractionating tower, a white clay tower, an isomerization reaction heating furnace, a heat exchanger II, a heat exchanger III, a heat exchanger IV, a heat exchanger VI and a compressor. According to the process, the operation load of the xylene tower is reduced, the fuel gas consumption of the xylene reboiler is reduced, meanwhile, the heat exchange network is optimized, the fuel gas consumption of the isomerization reaction heating furnace is reduced, the energy consumption is greatly reduced, and the economic benefit and the social benefit are improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Production device and production method of p-xylene

ActiveCN113121300AReduce loadTake advantage ofHydrocarbon by isomerisationDistillation purification/separationXylyleneIsomerization

The invention discloses a production device and a production method of p-xylene. The device comprises a xylene fractionation unit, an adsorption separation unit and an isomerization reaction unit, the adsorption separation unit comprises an adsorption separation tower, an extract tower, a raffinate tower, a finished product tower, a finished product tower reboiler I, a finished product tower reboiler II, a heat exchanger II and a heat exchanger III; the isomerization reaction unit comprises an isomerization reactor, a hydrogenation reactor, an isomerization product fractionating tower, an isomerization reaction heating furnace, a heat exchanger IV, a heat exchanger V and a compressor. The invention also provides a p-xylene production process. The invention reduces equipment investment and floor area, reduces the operation load of a xylene tower, saves the fuel gas consumption of a xylene reboiling furnace and an isomerization reaction heating furnace, improves the efficiency of removing olefin, carbonyl and other unsaturated hydrocarbons from the isomerization product, solves the problems of frequent replacement of spent bleaching clay and environmental pollution, optimizes the heat exchange network, the energy consumption is greatly reduced, and the economic benefit and the social benefit are improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Control method of gas heating and hot water supply equipment

ActiveCN110836414BReduce switching timesImprove experienceLighting and heating apparatusSpace heating and ventilation detailsWater useWater circulation

The invention discloses a control method of gas heating and hot water supply equipment. The gas heating and hot water supply equipment includes a gas furnace and a water tank; the control method includes: executing a zero cold water heating mode; the zero cold water heating mode includes: The water stored in the external pipeline connected to the gas heating and hot water supply equipment circulates into the water tank and is mixed with the water stored in the water tank before being output to the external pipeline. The water stored in the external water pipe is heated by the water tank to achieve the function of zero cold water, which effectively saves the consumption of gas and improves the user experience of water use.

Owner:QINGDAO ECONOMIC & TECHN DEV ZONE HAIER WATER HEATER +1

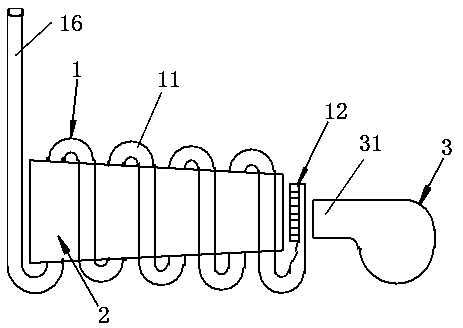

Rare earth water decomposition combustor and application method thereof

PendingCN108758626AEmission reductionSave gas consumptionHydrogen productionSteam generation plantsDecompositionRare earth

The invention discloses a rare earth water decomposition combustor and an application method thereof. The technical problems that due to traditional natural gas combustion, certain environment pollution is caused, and the industry and resident daily requirements cannot be met are solved. The rare earth water decomposition combustor comprises a steam generator, a rare earth device and a combustingmachine. The steam generator comprises a water pipe spirally wound around the rare earth device, one end of the water pipe is provided with a water inlet, and the other end of the water pipe is provided with an air spraying port adjacent to a firing hole of the combusting machine. Water is decomposed into hydrogen and oxygen to serve as fuel, and combustion is conducted to generate huge heat energy. Pollution is avoided after hydrogen and oxygen are combusted, only reductive water is generated, the rare earth water decomposition combustor is a very ideal environment-friendly and energy-savingdevice, and energy consumption is reduced.

Owner:HEBI BAOFA ENERGY SCI & TECH

A reaction system and method for batch production of chlorinated polyvinyl chloride

The invention discloses a reaction system and method for batch production of chlorinated polyvinyl chloride. The reaction system mainly includes a liquid chlorine vaporizer, a chlorine gas buffer tank, an activation reactor and a chlorination reactor. A chlorine buffer tank is connected, and an activation reactor is connected to the chlorination reactor. The reaction system of the present invention is not only suitable for the gas-solid phase chlorination reaction of polyvinyl chloride, but also suitable for the gas-solid phase chlorination reaction of other powders. It can not only be used as a chlorination reaction system alone, but also can be combined with other chlorination systems. Used together, it has good flexibility of use. The reaction system and method for intermittently producing chlorinated polyvinyl chloride of the present invention are low in cost, high in product quality, easy to control in operation, high in energy utilization rate, reduced in production cost, and can increase the chlorine content in chlorinated polyvinyl chloride to 65%. above.

Owner:中国平煤神马控股集团有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com