Waste hydrogen combustion system for full-hydrogen bell-type furnace used for bright annealing

A bright annealing and combustion system technology, applied in furnaces, heat treatment furnaces, furnace types, etc., can solve problems such as environmental pollution, waste hydrogen emissions, waste of energy, etc., and achieve the effects of avoiding damage or deformation, reducing gas consumption, and reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with accompanying drawing and embodiment:

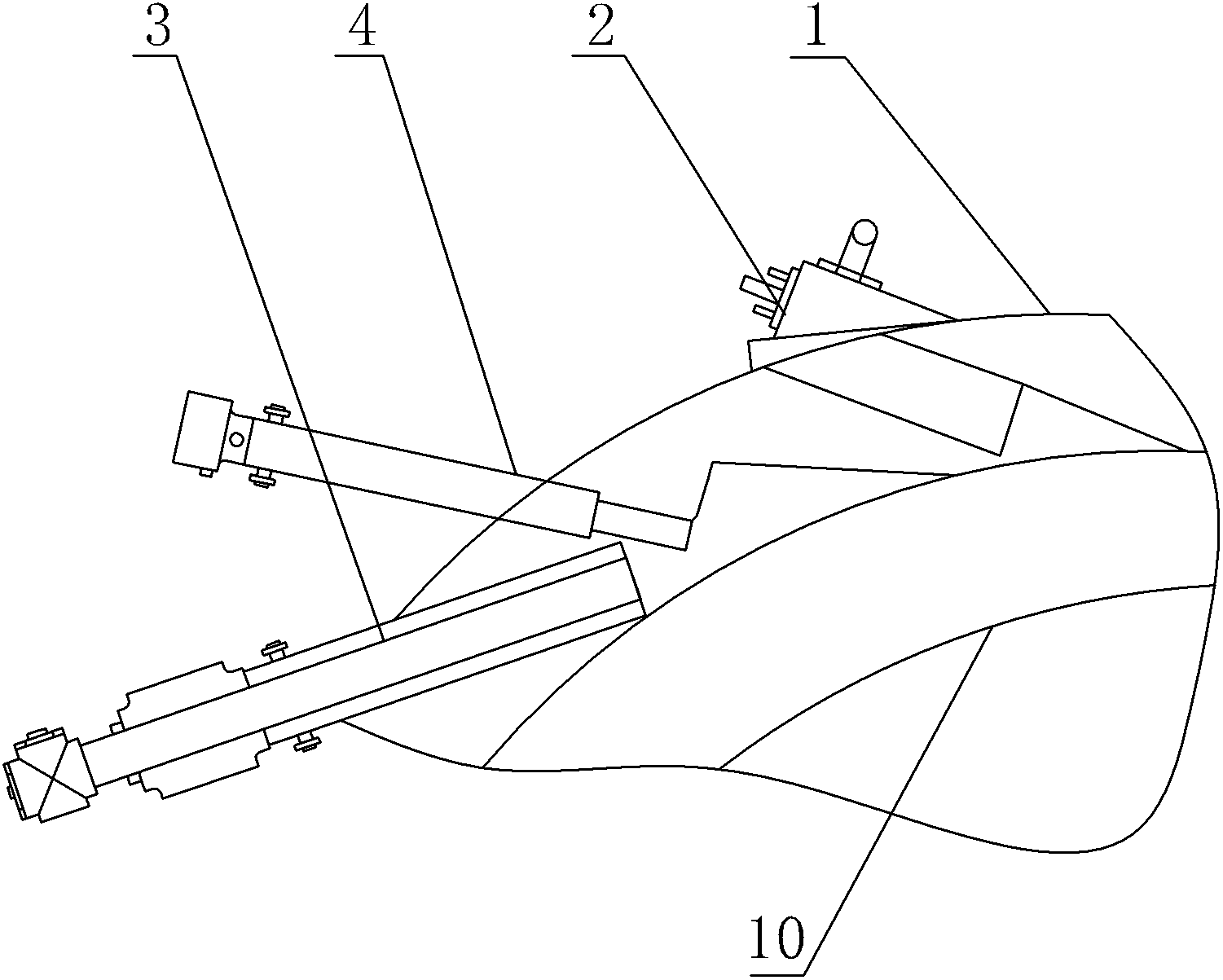

[0021] A full-hydrogen bell-type furnace waste hydrogen combustion system for bright annealing, including a main burner 2 fixed on a shell 1, a waste hydrogen burner 3 and an auxiliary burner 4, such as figure 1 Shown; the gas pipeline 5, the waste hydrogen pipeline 6 and the air pipeline 7 distributed on the shell 1, wherein: the air pipeline 7 is divided into a first branch pipe 70, a second branch pipe 71, a third branch pipe 72 and a fourth branch pipe 73.

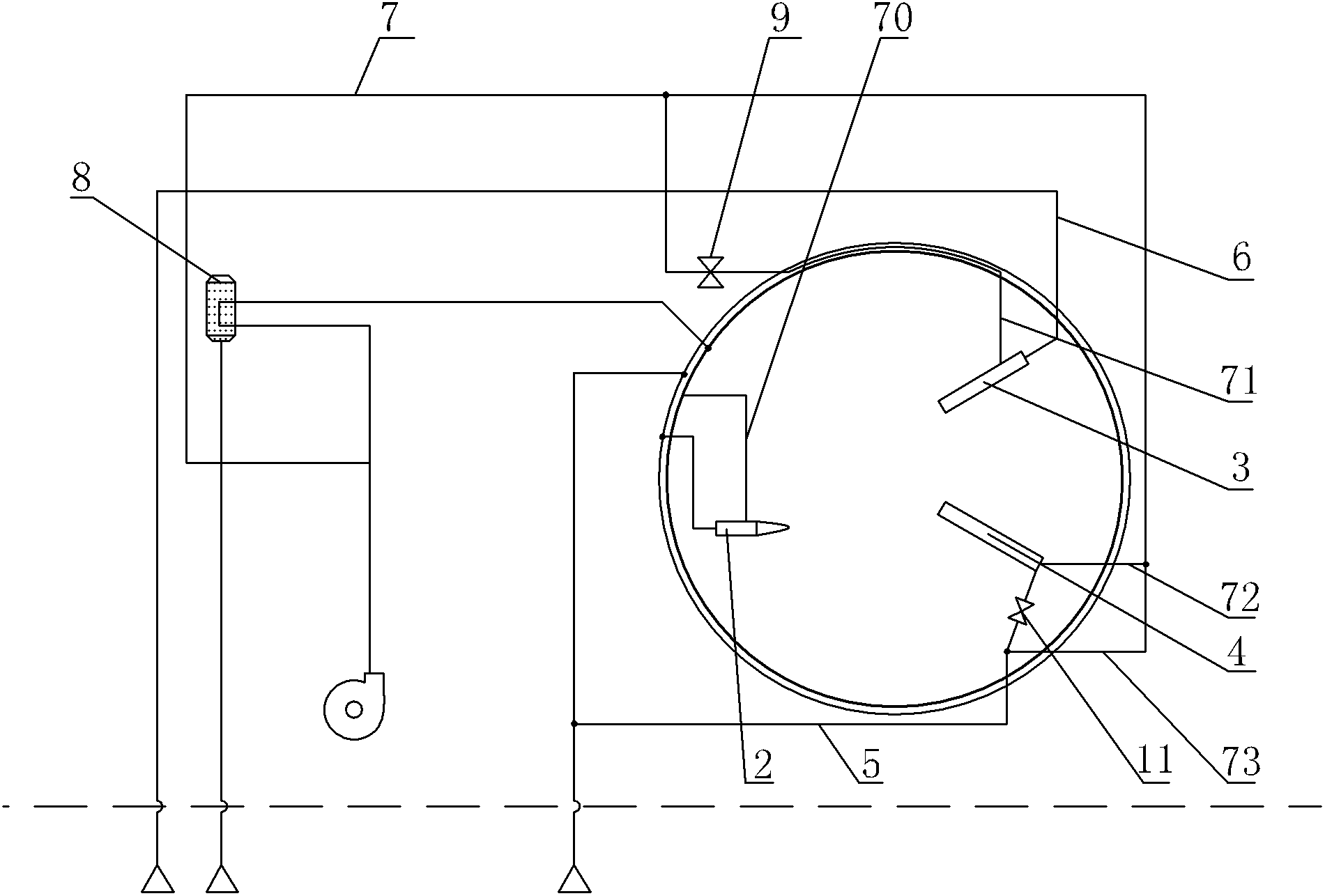

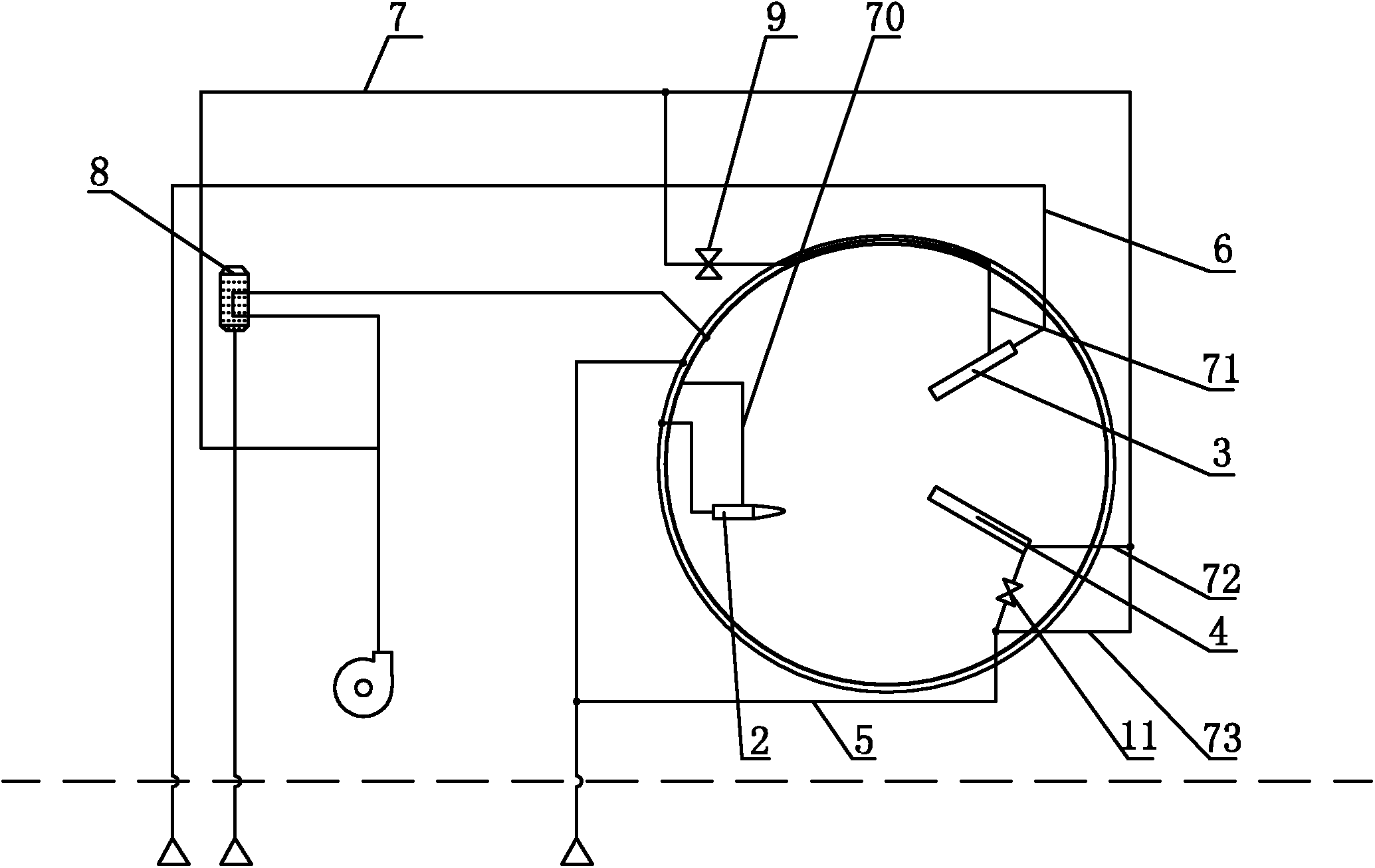

[0022] Such as figure 2 Shown:

[0023] The main burner 2 is mainly responsible for the heating work of the annealing furnace. The main burner 2 is respectively connected with the gas pipeline 5 and the first branch pipe 71, and the combustion-supporting air flowing through the first branch pipe 70 is preheated by the heat exchanger 8 and then mixed with the gas in the gas pipeline 5, and then ente...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com