Production device and process of aromatic hydrocarbon product

A production device and an aromatic technology, which are applied in the field of production of aromatic products, can solve the problems of increasing the operating load of a xylene tower, reducing the heat exchange efficiency of the isomerization reaction feed and discharge heat exchangers, and unreasonable energy utilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

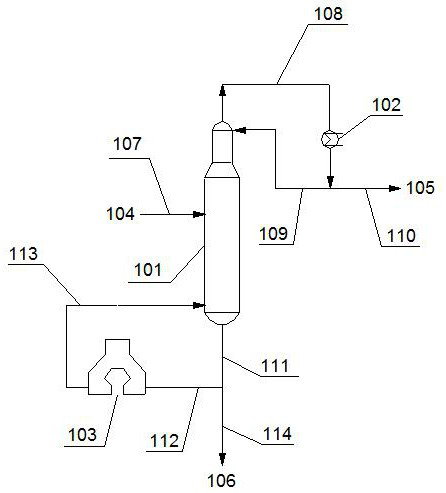

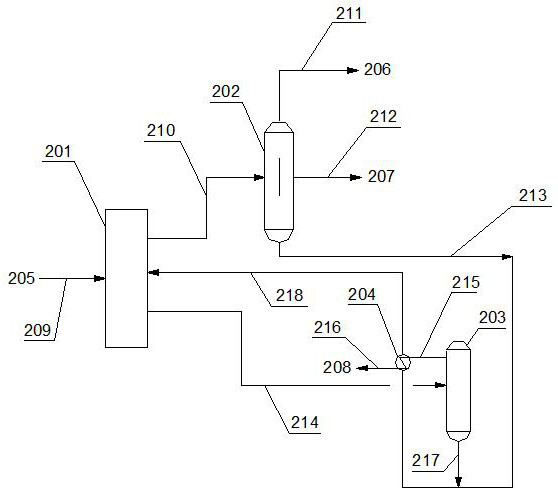

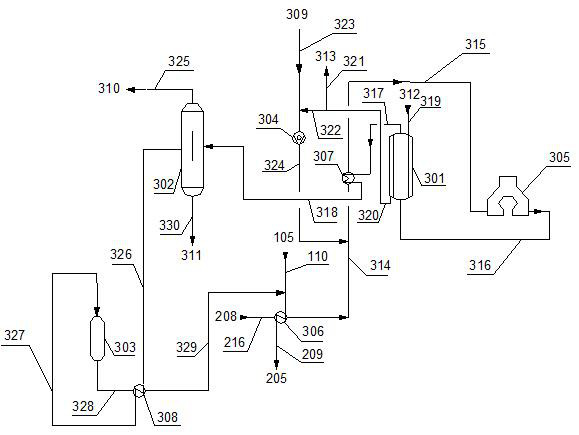

Image

Examples

Embodiment 1

[0062] Embodiment 1 illustrates the method and energy consumption of the novel p-xylene production process provided by the present invention. The equipment used is shown in Table 1, some key operating parameters are shown in Table 2, and the energy consumption of the device is shown in Table 3.

[0063] Table 1

[0064]

[0065] Table 2

[0066]

[0067] table 3

[0068]

[0069] As can be seen from Table 1, compared with Comparative Example 1, the method for producing p-xylene provided by the invention can save a set of rectification tower, cooler and reboiler equipment, and a heat exchanger, gas-liquid separation Investment in the number of tanks, air coolers and water coolers. The temperature of the isomerization reaction heating furnace is increased, the inlet pressure of the compressor is increased, and the purity of circulating hydrogen is improved, thereby reducing the fuel gas consumption of the heating furnace, reducing the power consumption of the compres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com