Zoned-temperature-control rotary continuous pyrolyzing and carbonizing device for biomass

A pyrolytic carbonization and rotary technology, applied in the direction of biofuel, special carbonization, indirect heating carbonization, etc., can solve the problems of low production efficiency, poor carbonization quality, heat loss, etc., to improve efficiency, fully respond, and save energy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technical solutions provided by the present invention will be described in detail below in conjunction with specific examples. It should be understood that the following specific embodiments are only used to illustrate the present invention and are not intended to limit the scope of the present invention.

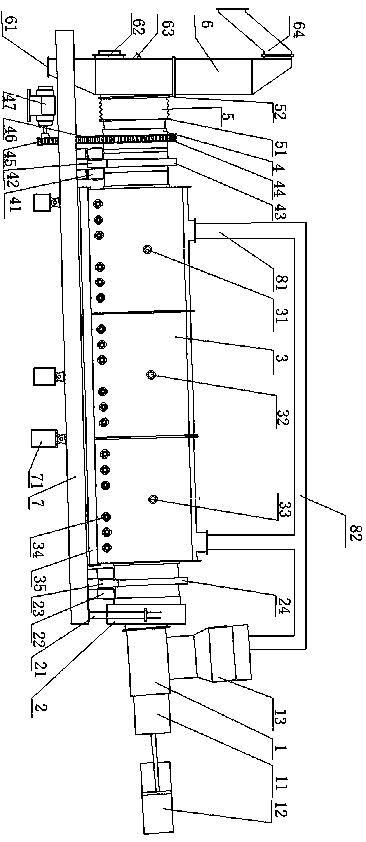

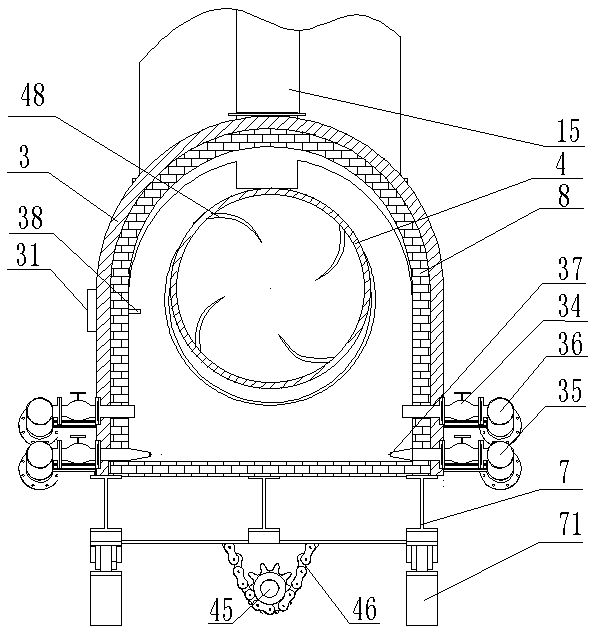

[0026] Please refer to the attached figure 1 , 2 , the partitioned temperature-controlled rotary biomass continuous pyrolysis carbonization device in the figure includes a tunnel kiln body 8 made of refractory bricks. The wall thickness of the kiln body is 150mm, forming a refractory insulation layer, and the kiln body shell is also wrapped around the kiln body 3. The shell is made of 8mm steel plate; a rotary furnace 4 is installed in the kiln body, and the rotary furnace 4 is in the shape of a long cylinder. The buffer device is connected with the furnace tail 6. The buffer device includes an expansion joint 5, and a first joint flange 51 and a second joint f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com