Energy-saving steaming and boiling system

A cooking pot and heat exchange chamber technology, which is applied in the boiler technology and food processing equipment field, can solve the problems of energy saving and consumption reduction and the incompatibility of meeting process requirements, scorched pot, dry pot, burner, incomplete combustion of gas, etc. Achieve the effects of improving heat absorption and utilization efficiency, reducing exhaust emissions, and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

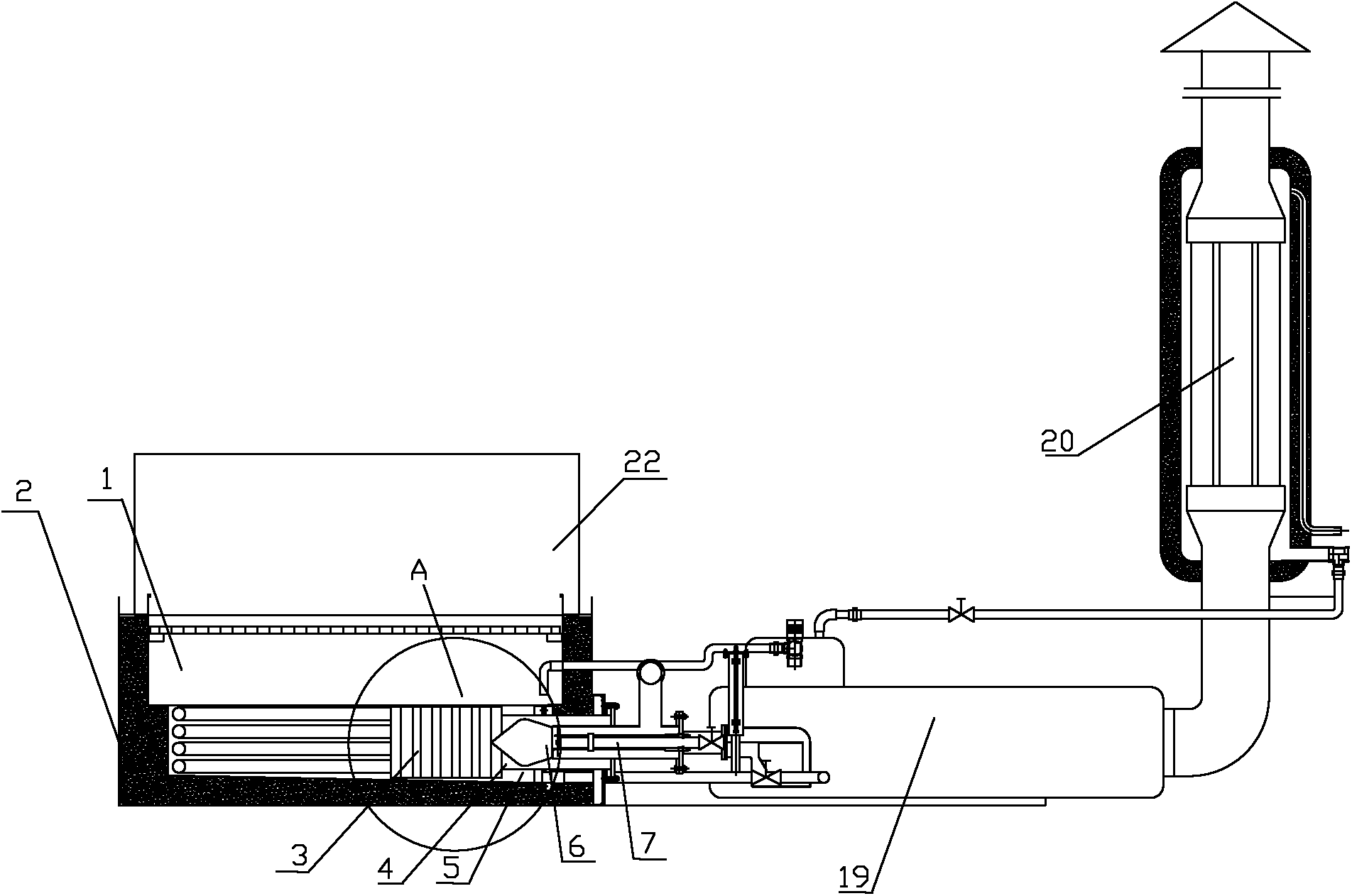

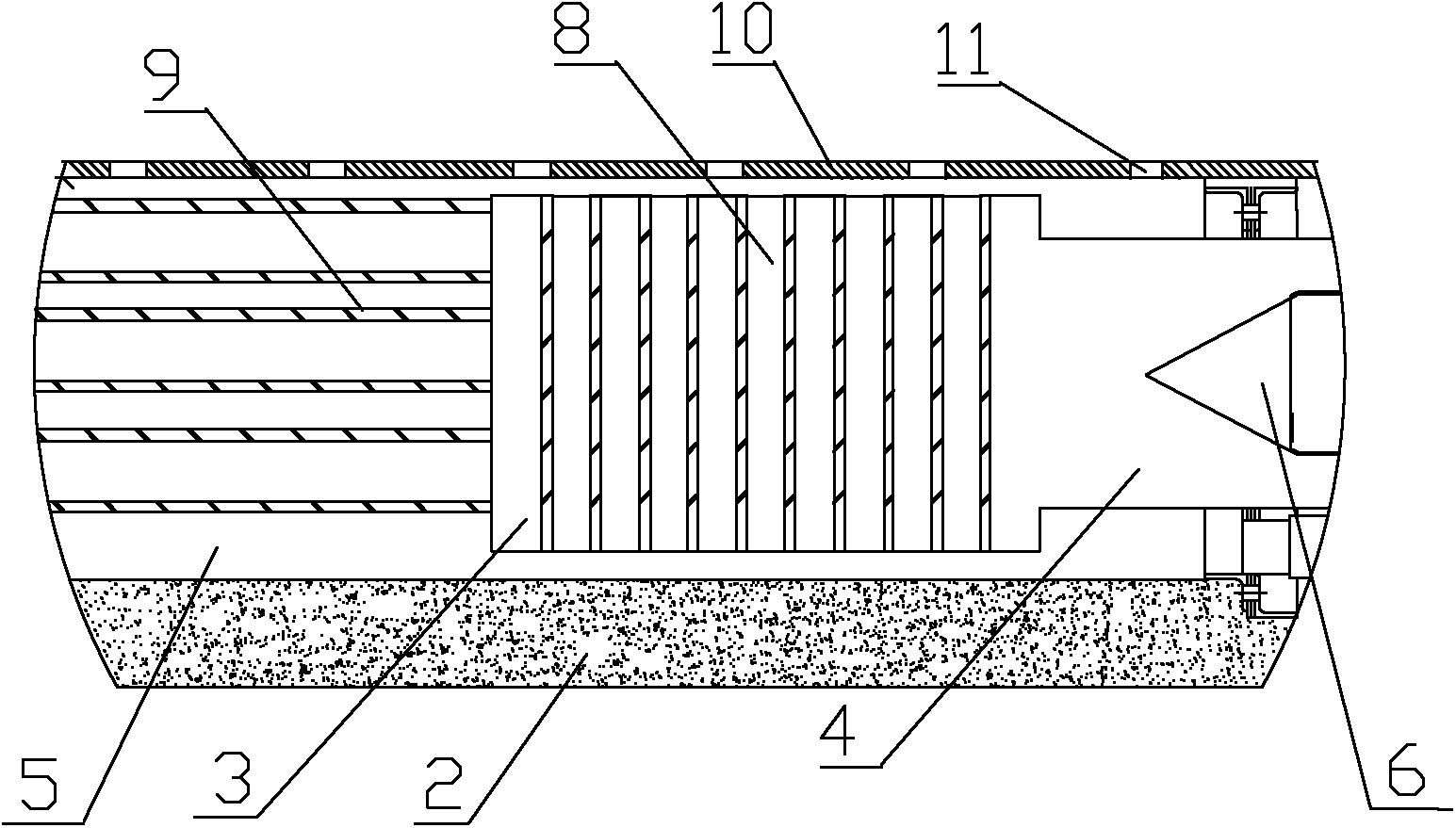

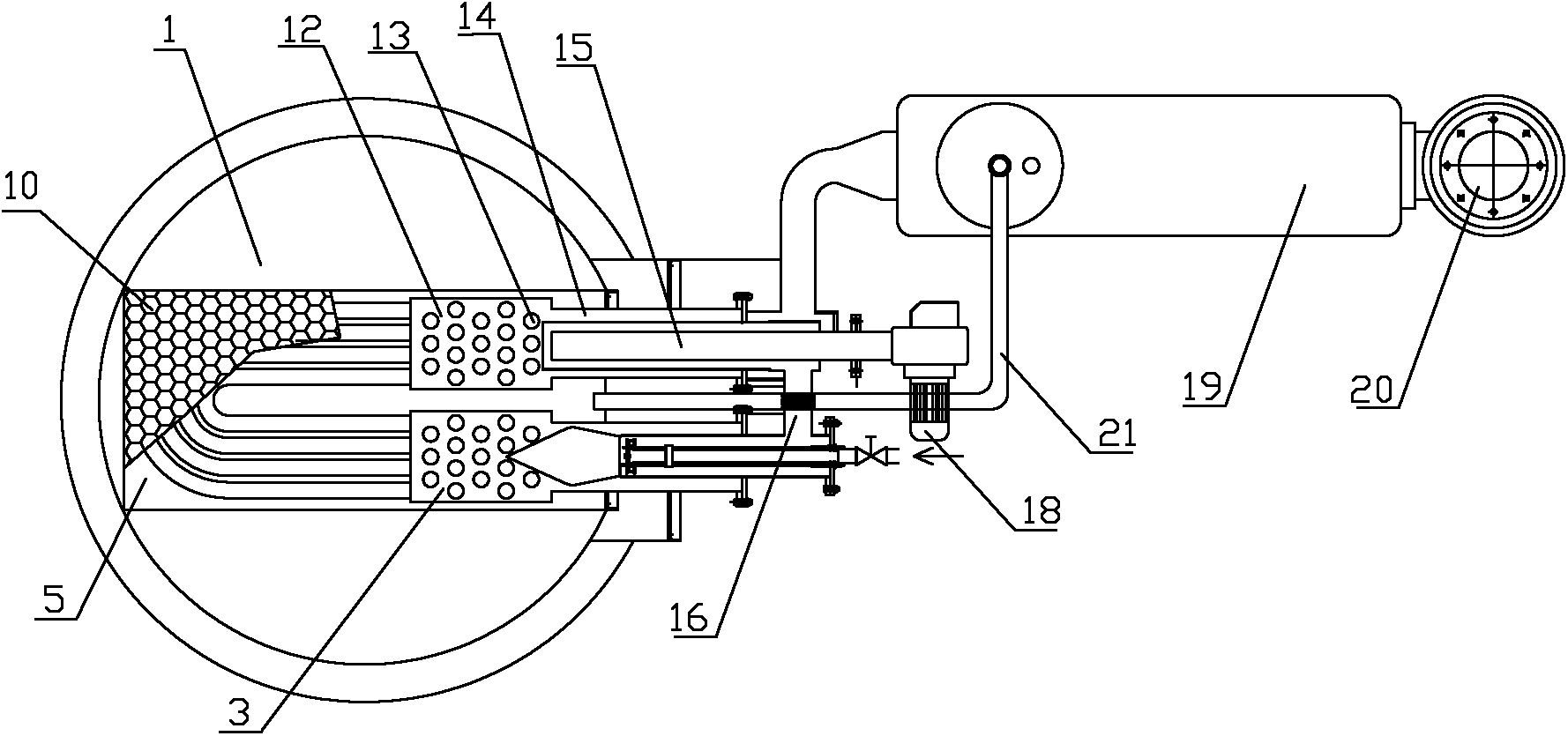

[0020] The energy-saving cooking system of the present invention includes a cooking pot 1 containing heated water for generating steam and a combustion chamber 4 below it for heating. A heat exchange tank 5 is installed below the cooking pot 1 , the inner chamber of the water exchange tank 5 communicates with the inside of the cooking pot 21 , and the heating water between them can flow mutually. The above-mentioned heat exchange tank 5 is provided with a high-temperature heat exchange chamber 3, and the inner cavity of the high-temperature heat exchange chamber 3 and the inner cavity of the water exchange tank 5 are in a closed structure, that is, the surrounding walls of the high-temperature heat exchange chamber 3 are all immersed in the water exchange tank. 5, while ensuring that the heating water in the heat exchange tank 5 cannot enter the inner cavity of the high-temperature heat exchange chamber 3. The inner cavity of the high-temperature heat exchange chamber 3 commun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com