Nickel hydroxide/thin-layer carbon nitride composite visible photocatalyst and preparation method thereof

A nickel hydroxide, photocatalyst technology, applied in physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of limited large-scale application, expensive platinum, etc., and achieve good storage hole characteristics, The effect of promoting separation and mild synthesis conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

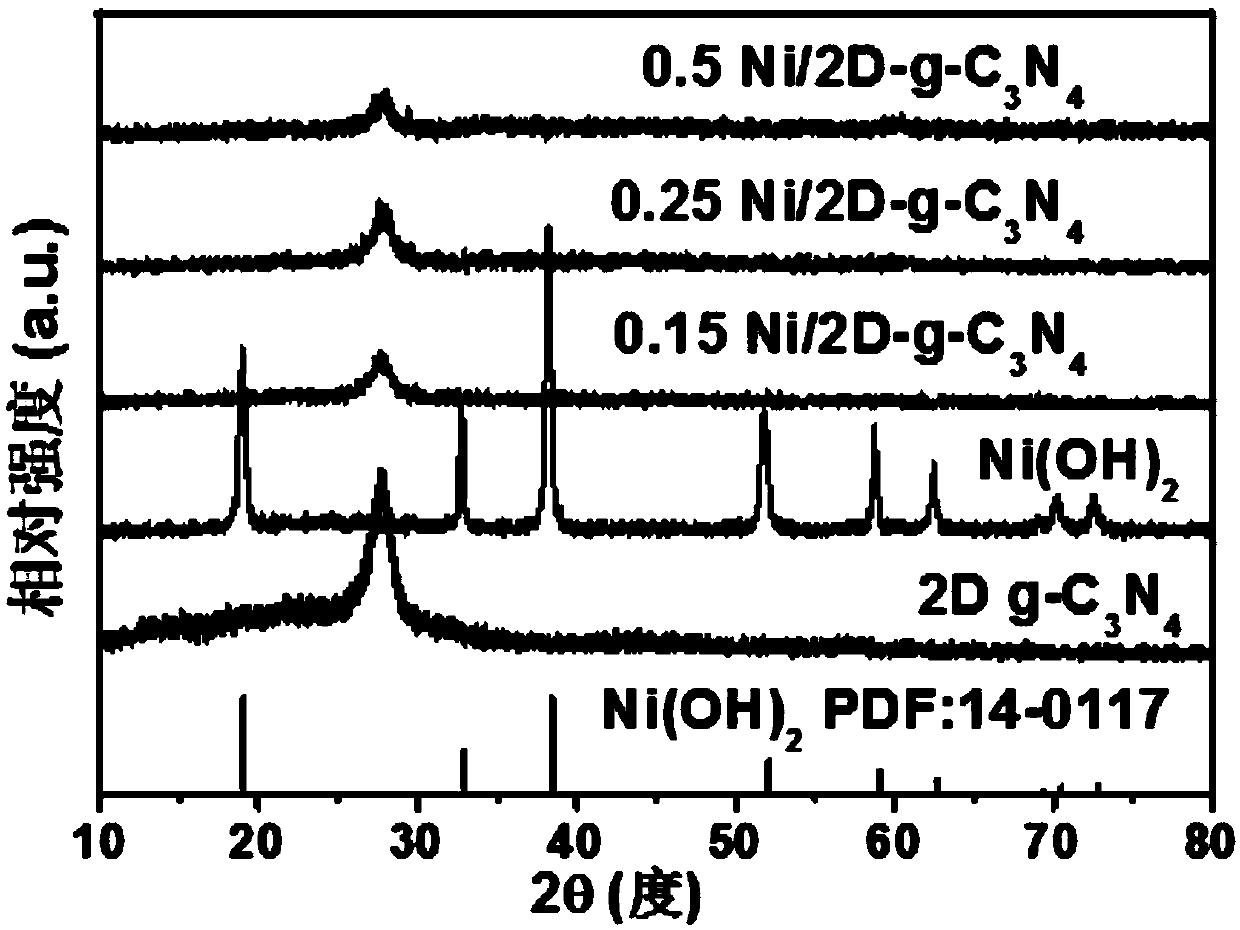

[0026] Embodiment 1: the preparation method of the nickel hydroxide / two-dimensional carbon nitride (nickel hydroxide molar number is 0.25nmol) composite photocatalyst of visible light response of the present invention, specifically comprises the following steps:

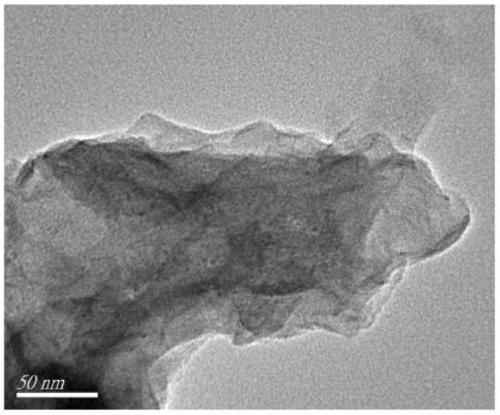

[0027] Step 1: Put 2g of melamine in a ceramic crucible with a cover, heat up to 550°C for 4 hours in a muffle furnace at a rate of 2°C / min, and calcinate the obtained yellow substance into powder, then spread 400mg of the yellow powder on the ark In a muffle furnace, the temperature was raised to 550°C at a rate of 5°C / min and calcined for 1h, and the temperature was naturally cooled to room temperature; then the temperature was raised to 550°C at a rate of 2°C / min and calcined for 1h to obtain carbon nitride with a two-dimensional sheet structure. .

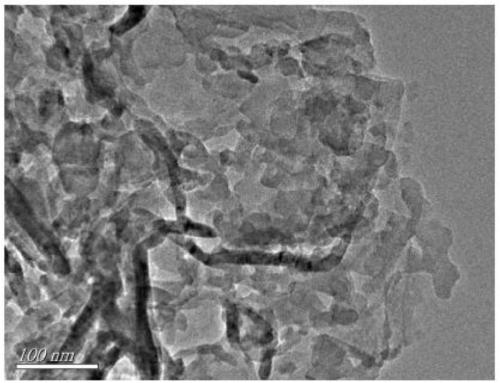

[0028] The second step: take 100mg of two-dimensional carbon nitride and 0.25mmol of nickel nitrate hexahydrate and place them in deionized water for 20 minutes to di...

Embodiment 2

[0032] Embodiment 2: In order to control and optimize material performance, the preparation method of nickel hydroxide / two-dimensional carbon nitride (nickel hydroxide molarity is 0.15nmol) composite photocatalyst of visible light response of the present invention specifically comprises the following steps:

[0033] Step 1: Put 2g of melamine in a ceramic crucible with a cover, heat up to 550°C for 4 hours in a muffle furnace at a rate of 2°C / min, and calcinate the obtained yellow substance into powder, then spread 400mg of the yellow powder on the ark In a muffle furnace, the temperature was raised to 550°C at a rate of 5°C / min and calcined for 1h, and the temperature was naturally cooled to room temperature; then the temperature was raised to 550°C at a rate of 2°C / min and calcined for 1h to obtain carbon nitride with a two-dimensional sheet structure. .

[0034] The second step: take 100mg of two-dimensional carbon nitride and 0.15mmol of nickel nitrate hexahydrate and plac...

Embodiment 3

[0038] Embodiment 3: In order to further control and optimize the material performance, the preparation method of the nickel hydroxide / two-dimensional carbon nitride (nickel hydroxide molar number is 0.5nmol) composite photocatalyst of visible light response of the present invention, specific Include the following steps:

[0039] Step 1: Put 2g of melamine in a ceramic crucible with a cover, heat up to 550°C for 4 hours in a muffle furnace at a rate of 2°C / min, and calcinate the obtained yellow substance into powder, then spread 400mg of the yellow powder on the ark In a muffle furnace, the temperature was raised to 550°C at a rate of 5°C / min and calcined for 1h, and the temperature was naturally cooled to room temperature; then the temperature was raised to 550°C at a rate of 2°C / min and calcined for 1h to obtain carbon nitride with a two-dimensional sheet structure. .

[0040] The second step: take 100mg of two-dimensional carbon nitride and 0.5mmol of nickel nitrate hexahy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com