Distillation process and multi-column heat-integrated distillation system

A distillation system and distillation tower technology, applied in the field of distillation systems, can solve problems such as low energy efficiency, achieve high energy efficiency, and reduce the number of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 2

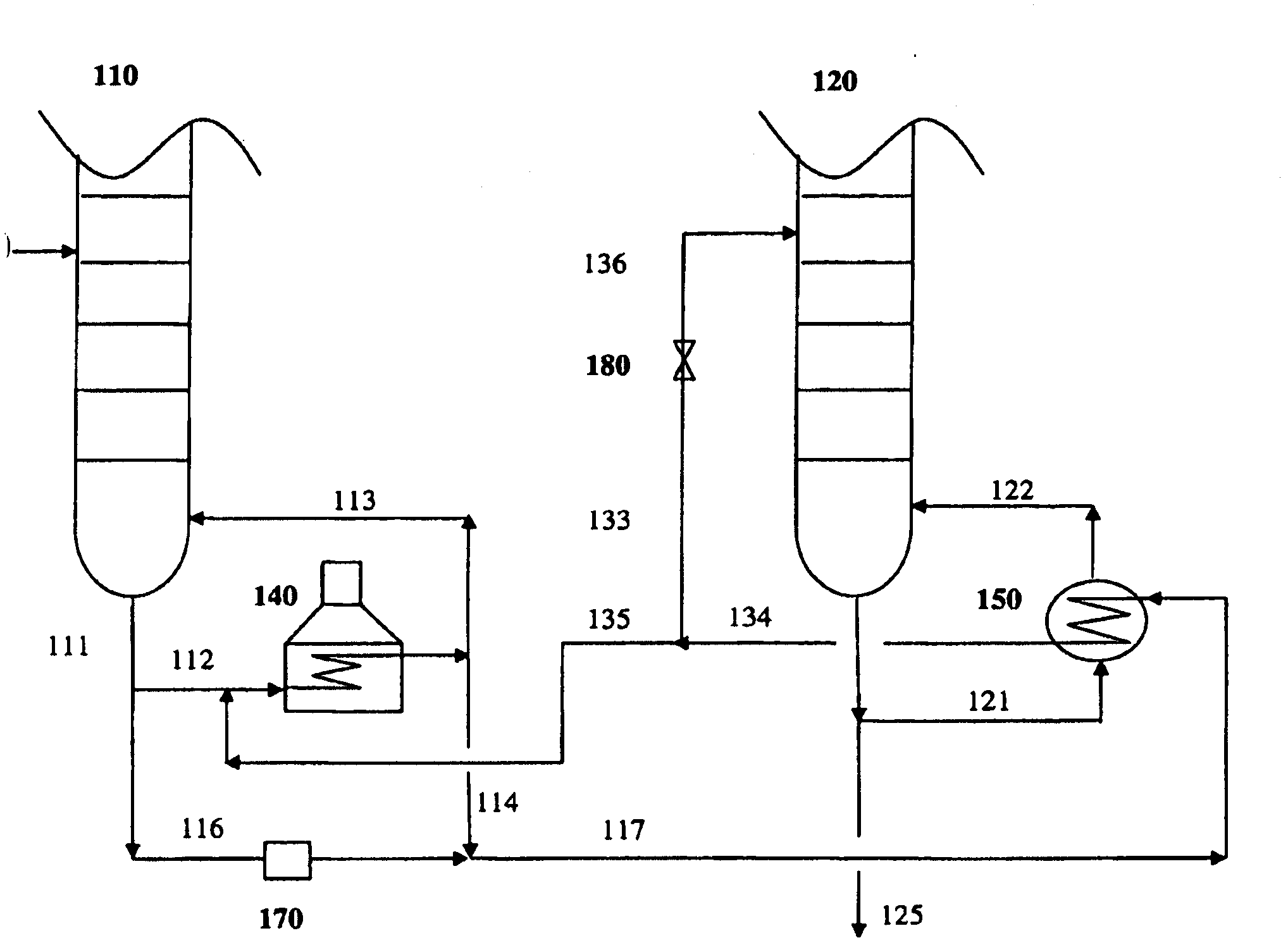

[0058] For the setup used in Comparative Experiment 1, the initial feed flow to the second column was completely stopped and the feed heat exchanger was removed. Instead, use a portion of the second reboiler outlet stream (i.e. from the common stream) as the second column feed and pass it through an expansion valve to further adjust its pressure and reduce its pressure before entering the second column as feed. temperature. The balance stream from the second reboiler was fed upstream of the first fired heater of the first (xylene) column. This situation is related to figure 1 The scheme shown in is similar; using a pump but without stream 114 from the first reboiler. The distillation operating parameters after the above changes of the present invention are given in Table 1.

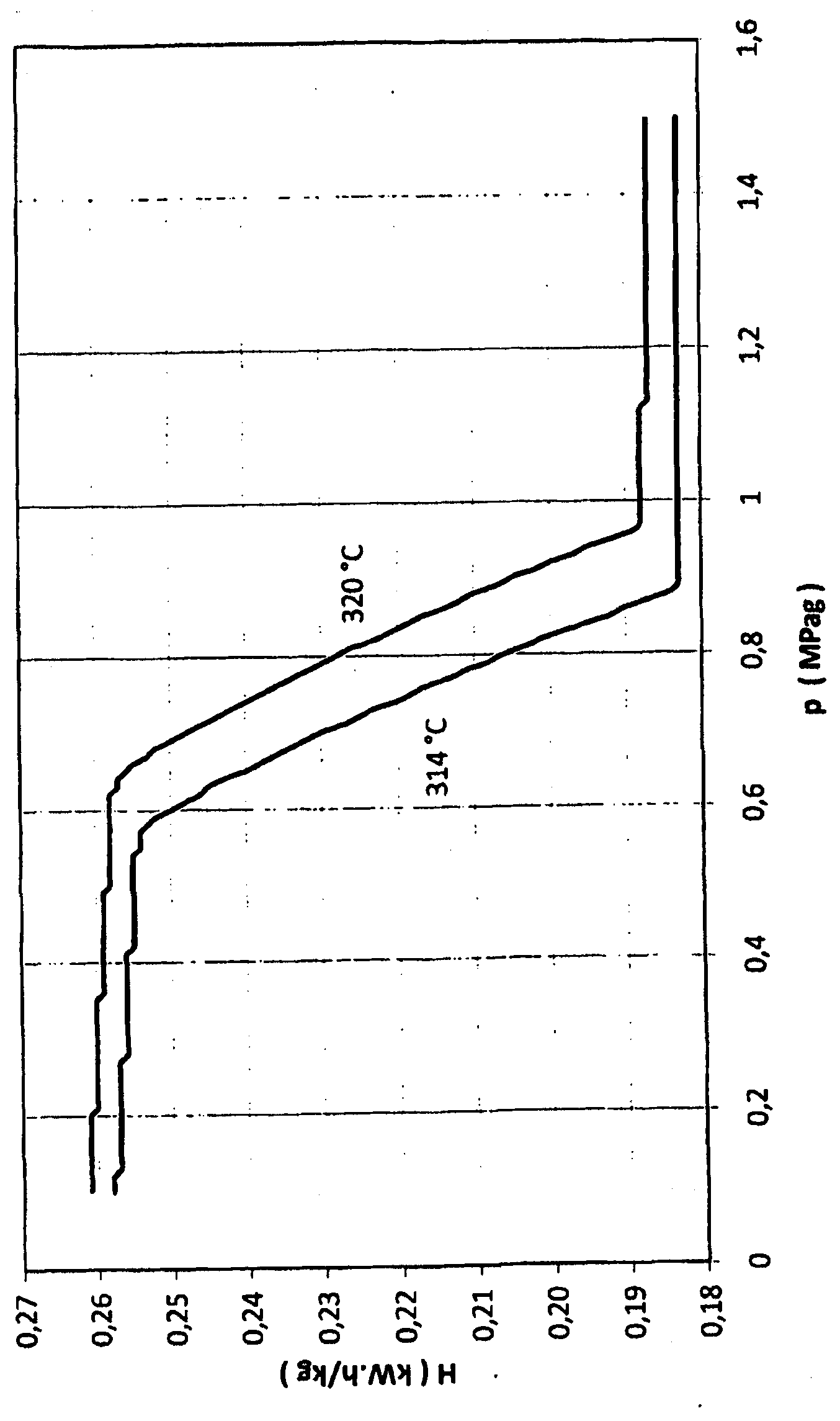

[0059] These results clearly show that, for Example 2, the calculated fired reboiler energy load required to reheat the second reboiler balance stream back to its original temperature (i.e. 314°C), min...

example 3

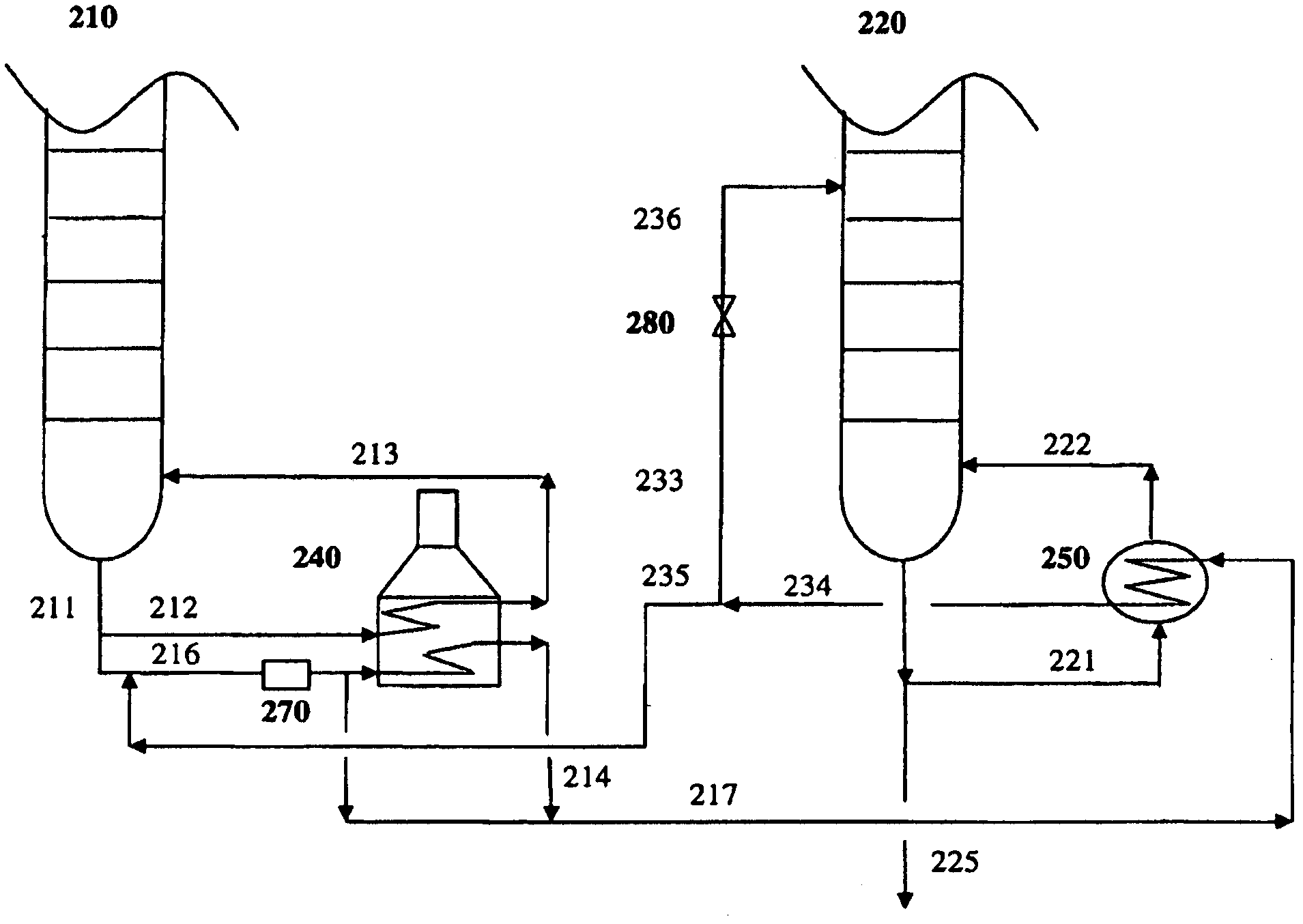

[0064] refer to image 3, it can be seen that although an inlet pressure of 2.1 MPag lies in the flat section of the enthalpy change for a stream at a temperature of 314°C, it is possible - see Example 2 - by using the reboiler outlet stream as the column feed and the A downstream expansion valve was used to further cool the feed and regulate its pressure, saving energy in heat load and improving the separation efficiency of the column. It also shows that further improvements can be made, for example by minimizing the reboiler flow back to the upstream fired reboiler. Example 3 represents simulation results based on Example 2 and using commercially available software. In Example 3, the stream pressure was reduced below the xylene bottoms pressure, which can actually be achieved using a pressure reducing valve, with additional heating to the initial feed inlet temperature (e.g. figure 1 structure shown using stream 114 or figure 2 structure shown utilizing stream 214).

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com