Iron-containing material treating system and application thereof to treatment of iron-containing materials

A material and feeding port technology, which is applied in the field of iron-containing material processing, can solve the problems of accelerated electrode material consumption, unstable combustion, and narrow raw material applicability, so as to avoid the difficulty in increasing the height of the molten pool and avoid heating and heat conduction. The effect of poor and wide applicability of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

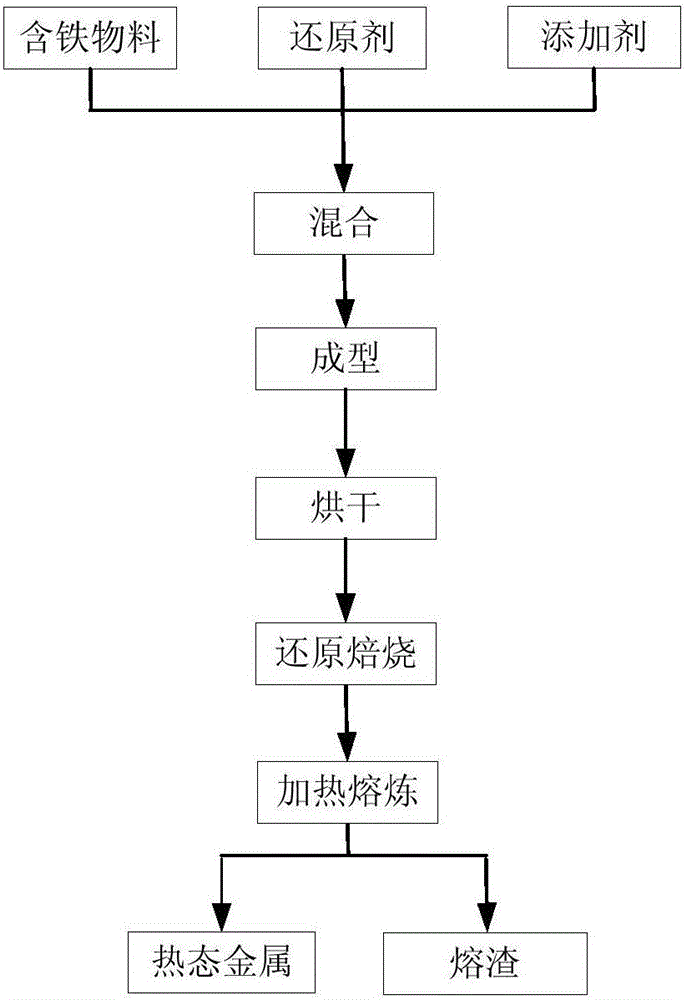

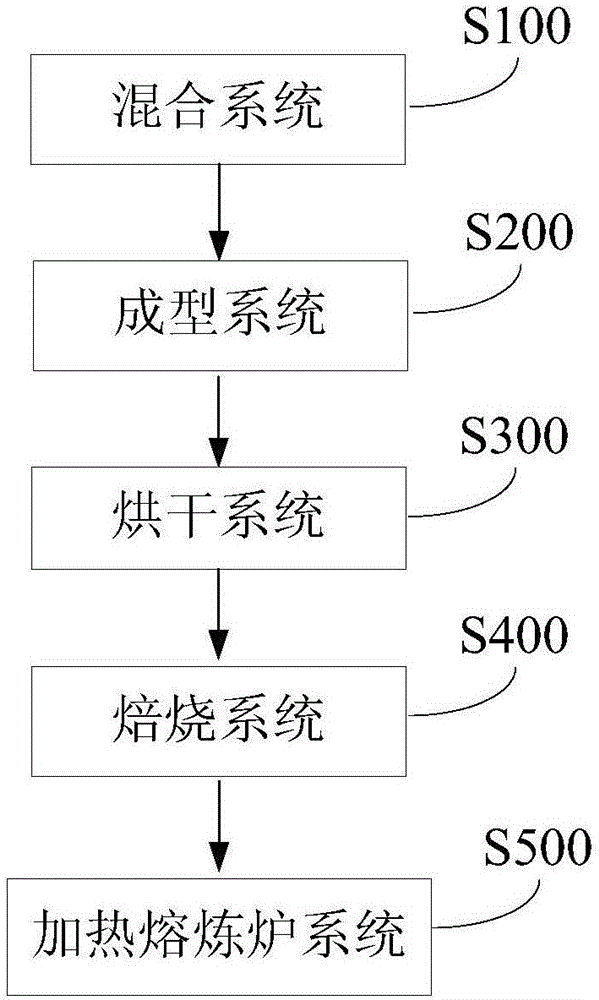

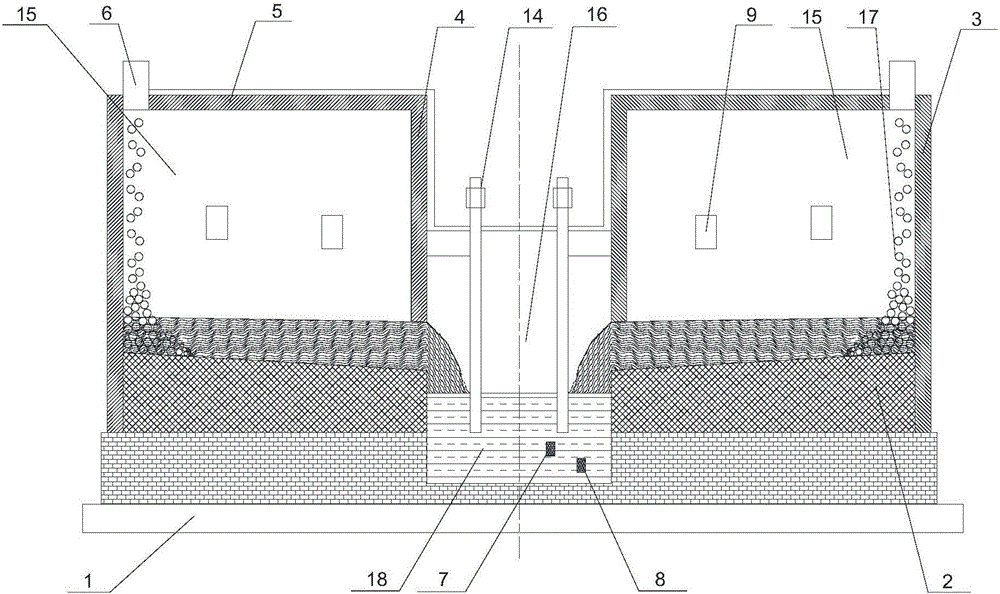

[0053] A system for processing iron ore, which mixes iron ore and reduced coal evenly in the mixing system S100, and then dries them in the drying system S300 after forming pellets in the forming system S200, and the dried pellets are in the roasting system S400 After reduction roasting, it is put into the heating and melting furnace system S500 for melting. The structure of the heating and melting furnace system S500 is as follows: image 3 As shown, it includes a furnace foundation 1, a refractory material furnace bottom 2, a furnace body side wall 3 made of refractory bricks and refractory materials with a built-in cooling copper water jacket, a partition wall 4 between the melting zone 15 and the settlement zone 16, Furnace roof 5 above the furnace, feed inlet 6 above the furnace roof 5 in the melting zone 15, slag outlet 7 and hot metal outlet 8 in the settling zone 16, and 5 holes on the walls on opposite sides of the melting zone 15 Set of regenerative burner burners 9...

specific Embodiment approach 2

[0058] A system for processing copper slag, which mixes copper slag, reduced coal and limestone uniformly in a mixing system S100 according to a certain proportion, and then dries them in a drying system S300 after being made into pellets in a forming system S200. After the dough is reduced and roasted in the roasting system S400, the reduced product is mixed with a certain amount of quicklime and put into the heating and smelting furnace system S500 for smelting. The structure of the heating and melting furnace system S500 is as follows: image 3 Shown: including furnace foundation 1, refractory material furnace bottom 2, furnace body side wall 3 built by refractory bricks and refractory material with built-in cooling copper water jacket, partition wall 4 between melting zone 15 and settlement zone 16, The furnace roof 5 above the furnace, the feed inlet 6 above the furnace roof 5 in the melting zone 15, the slag outlet 7 and the hot metal outlet 8 below the settling zone 16,...

specific Embodiment approach 3

[0063] A system for treating nickel slag, mixing nickel slag, blue coke and soda ash evenly in a certain proportion in the mixing system S100, making pellets in the forming system S200 and drying in the drying system S300, the dried pellets After the dough is reduced and roasted in the roasting system S400, the reduced product is added with a certain amount of fluorite and put into the heating and melting furnace system S500 for melting. The structure of the heating and melting furnace system S500 is as follows: image 3 Shown: including furnace foundation 1, refractory material furnace bottom 2, furnace body side wall 3 built by refractory bricks and refractory material with built-in cooling copper water jacket, partition wall 4 between melting zone 15 and settlement zone 16, The furnace roof 5 above the furnace, the feed inlet 6 above the furnace roof 5 in the melting zone 15, the slag outlet 7 and the hot metal outlet 8 below the settling zone 16, and the walls on opposite ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com