Production device and production method of p-xylene

A technology for para-xylene and production equipment, which is applied in the production of bulk chemicals, chemical instruments and methods, and purification/separation of hydrocarbons. Cracking, saving consumption, reducing the effect of aromatic saturation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

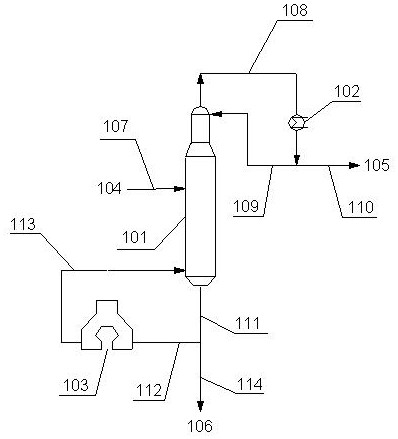

[0055] The production device of p-xylene, including xylene fractionation unit, adsorption separation unit and isomerization reaction unit;

[0056] Described xylene fractionation unit such as figure 1 shown, including: will contain C 8 Aromatic hydrocarbon mixture raw material 104 is fed to the feed line 107 of the xylene tower; the tower top discharge is sent to the pipeline 108 of the heat exchanger I102; a part of the tower top discharge after heat exchange by the heat exchanger I102 is recycled back to xylene The pipeline 109 of the tower; another part of the tower top discharge 105 after the heat exchange of the heat exchanger I102 is sent to the pipeline 110 of the heat exchanger IV306; a part of the bottom material 111 is sent to the feed pipeline of the reboiler 103 at the bottom of the tower 112; The pipeline 113 that is used to circulate the tower bottom material heated by the tower bottom reboiler 103 back to the xylene tower; Another part of the tower bottom mater...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com