Optic fiber prefabricated loose mass deposition device and deposition method thereof

A deposition device and deposition method technology, applied in glass deposition furnaces, manufacturing tools, glass manufacturing equipment, etc., can solve the problems of production costs and increase production efficiency, and can save gas consumption and improve production efficiency by adding blowtorches. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

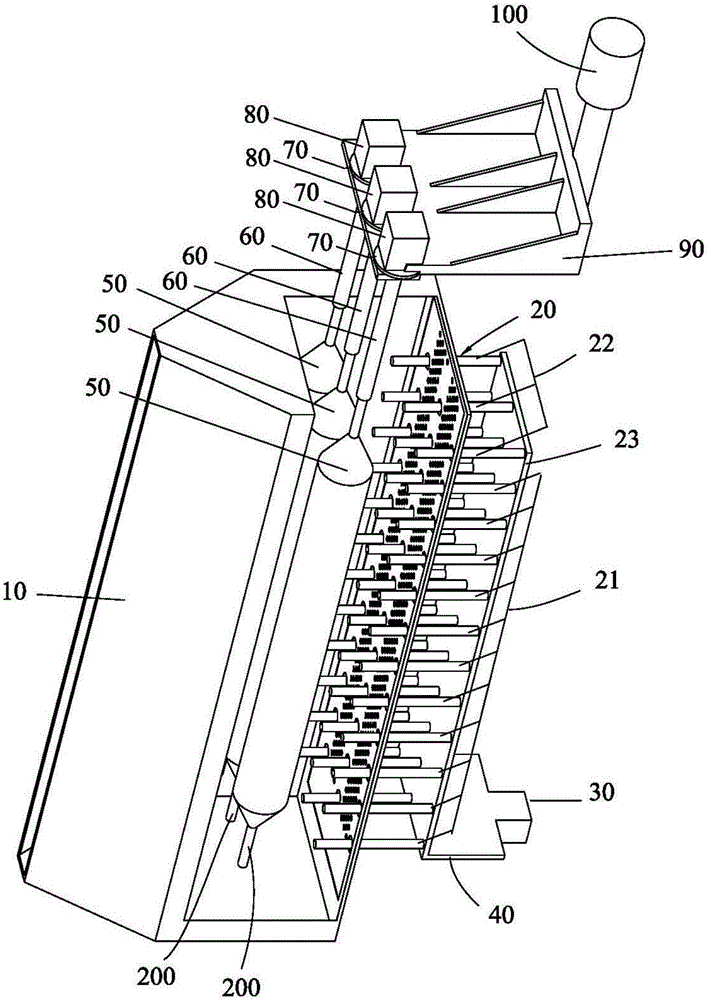

[0032] The invention provides a fiber prefabricated loose body deposition device, which can be used for SiCl 4 Hydrolytic deposition produces optical fiber prefabricated loose body or organosilicon combustion deposition produces optical fiber preformed rod loose body.

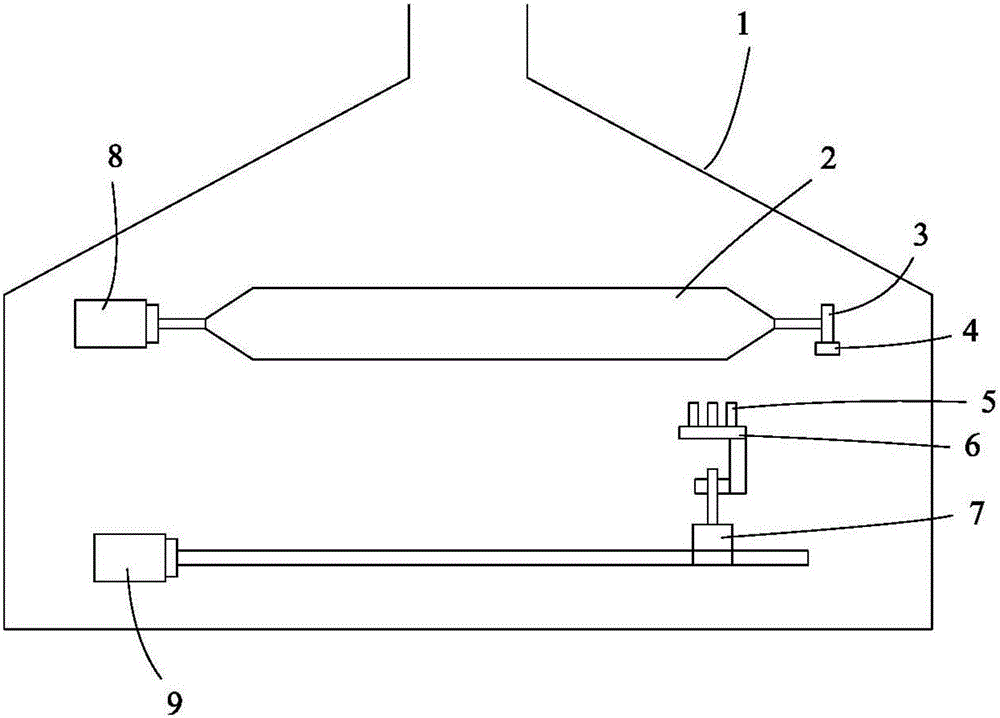

[0033] see figure 1 As shown, the deposition device includes: a box body 10, an R×C matrix distribution torch 20 fixed in the box body 10, a torch translation motor 30 connected to the R×C matrix distribution torch 20, and a torch translation platform 40, C A target rod 200, C lead rods 60 correspondingly connected to the C target rods 200, C sensors 70 correspondingly connected to the C lead rods 60, C rotating motors correspondingly connected to the C lead rods 60 80 . The elevating platform 90 for fixing the C rotating motors 80 , and the elevating motor 100 connected with the elevating platform 90 . Among them, 4≤R≤12, 1≤C≤6, R≥C; the guide rod 60 is fixed on the lifting platform 90; the sensor 70 is a we...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com