Production device and production process of p-xylene

A p-xylene and xylene technology, applied in the field of p-xylene production equipment, can solve problems such as unreasonable energy utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

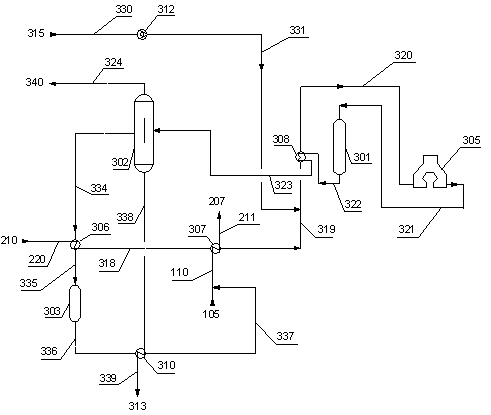

[0067] Embodiment 1 illustrates the method and energy consumption of the novel p-xylene production process provided by the present invention, wherein the overhead product of the isomerization fractionation tower directly leaves the device without separation, and the hydrogen required for the isomerization reaction is boosted by a compressor , mixed with the isomerization reaction feed. The energy consumption of the device is shown in Table 1.

[0068] Table 1

[0069] Example Comparative example 1 Example 1 process flow routine process Process of the invention Condensing cooling load / MW 109.2 88.2 Reboiler load / MW 97.3 79.8

[0070] As can be seen from Table 1, compared with Comparative Example 1, the energy consumption of the method for producing p-xylene provided by the present invention is reduced by 18.2%. Therefore, adopting the novel p-xylene production method provided by the present invention can reduce the operating load of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com