Tapered spiral filling

A technology of spiral packing and taper, applied in chemical/physical/physical chemical process, chemical instrument and method, chemical/physical process, etc., can solve the problems of small separation factor, large flow resistance, easy blockage, etc., and achieve strong self-cleaning Ability, simple structure, not easy to block the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

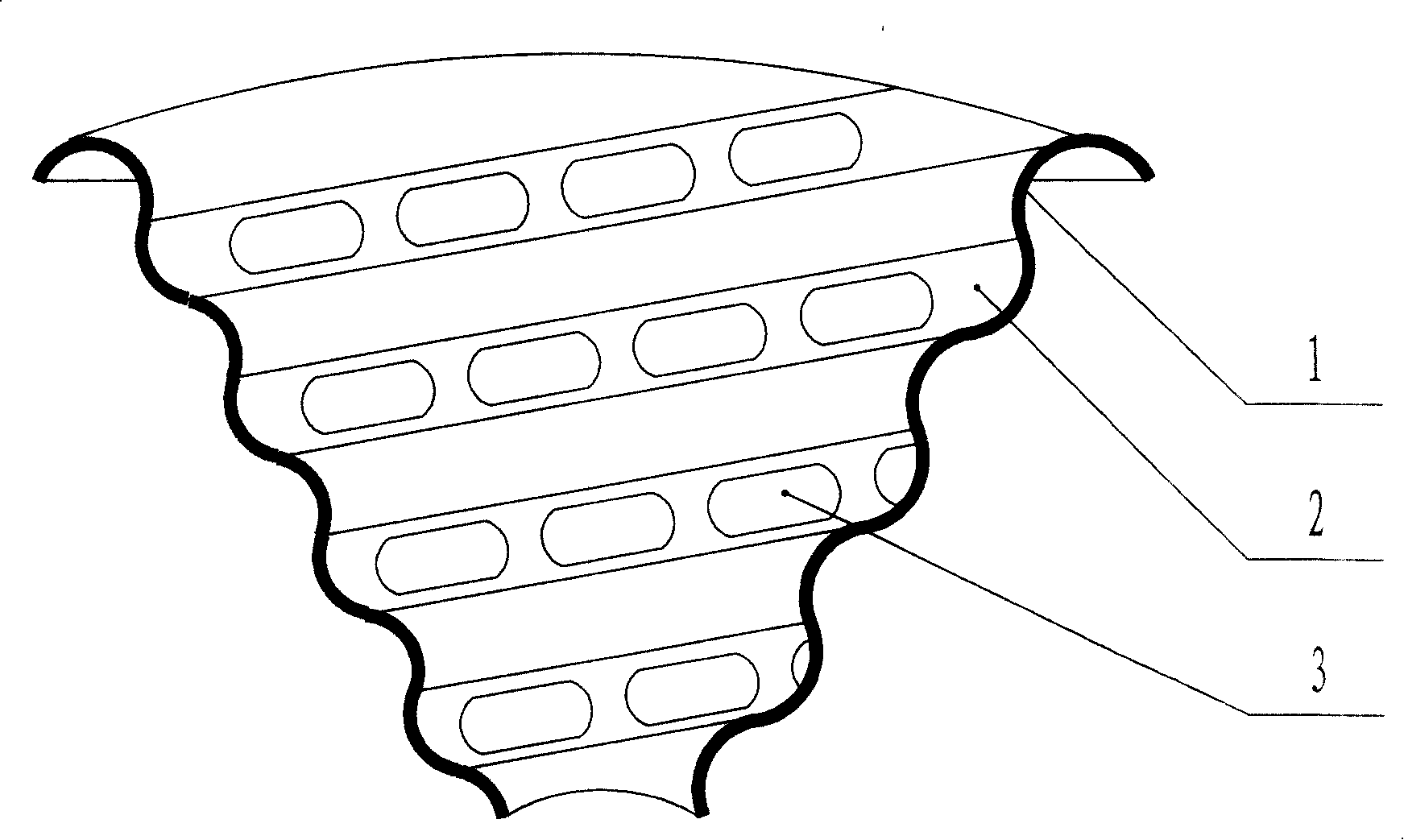

[0015] Example 1: Sieve Basket Taper Spiral Packing

[0016] Such as figure 1 As shown, a kind of taper spiral filler has a spiral flow groove 2 on the inner surface of the hollow cone 1, and a vent hole 3 is arranged on the bottom of the spiral flow groove 2. The spiral flow groove 2 can be a single-head spiral flow groove or can be It is a multi-head spiral trough, the cross section of the spiral trough 2 is arc-shaped, there are intermittent ventilation holes 3 on the bottom of the spiral trough 2, and the longitudinal section of the hollow cone 1 is wavy.

Embodiment 2

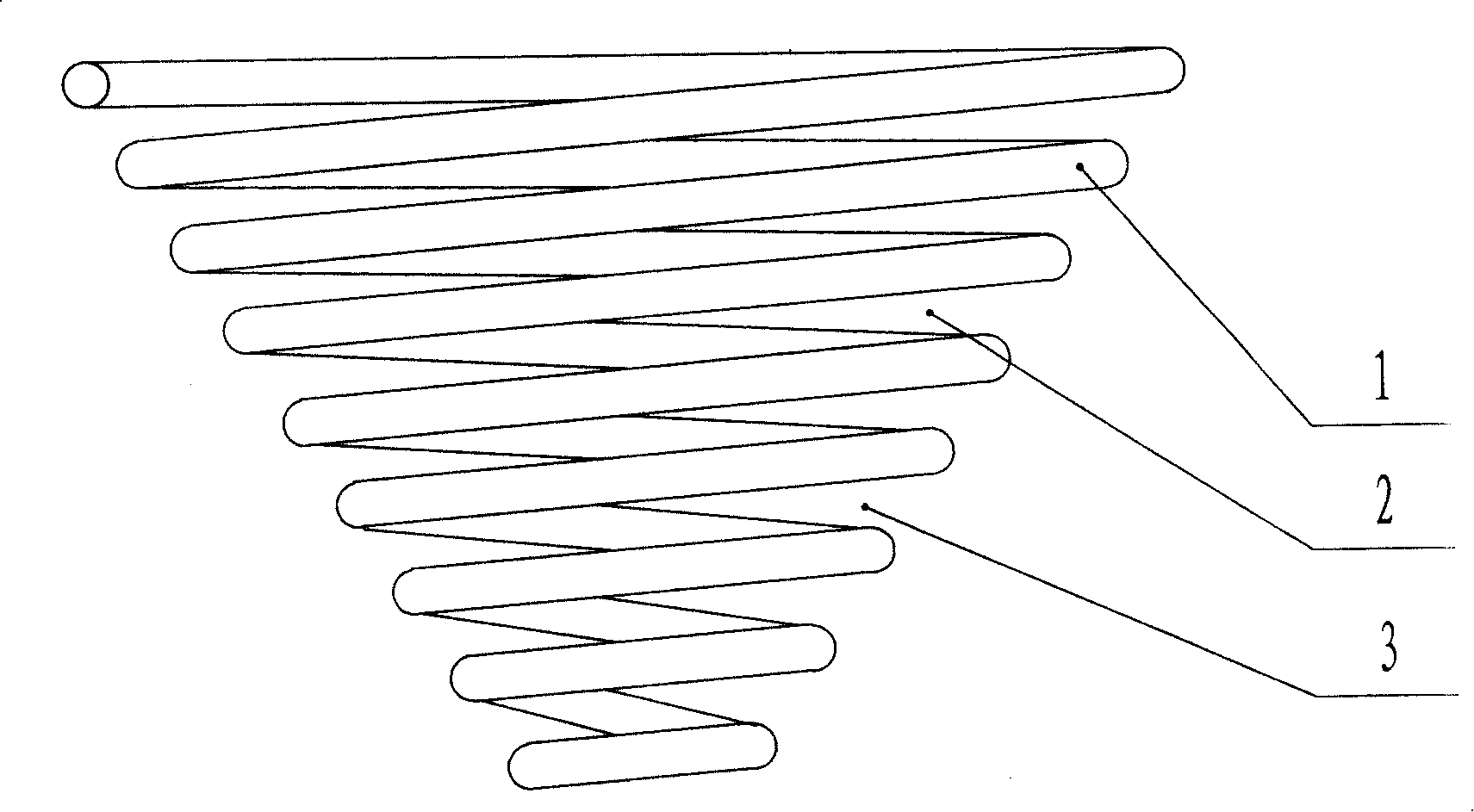

[0017] Example 2: Pagoda spring-like tapered spiral packing

[0018] Such as figure 2 As shown, a kind of tapered spiral packing, the spiral flow groove 2 on the inner surface of the hollow cone 1 is a single-head spiral flow groove, and the air hole 3 on the bottom of the spiral flow groove 2 is a continuous air hole, so that the tapered spiral packing can see Like a pagoda spring. This embodiment can also be formed by winding (or injection molding) wire rods.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com