switchgear

A technology of switch devices and contact parts, applied in the direction of electric switches, emergency protection devices, emergency connections, etc., can solve the problem of small operating load, and achieve the effect of increased operating load and large operating load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

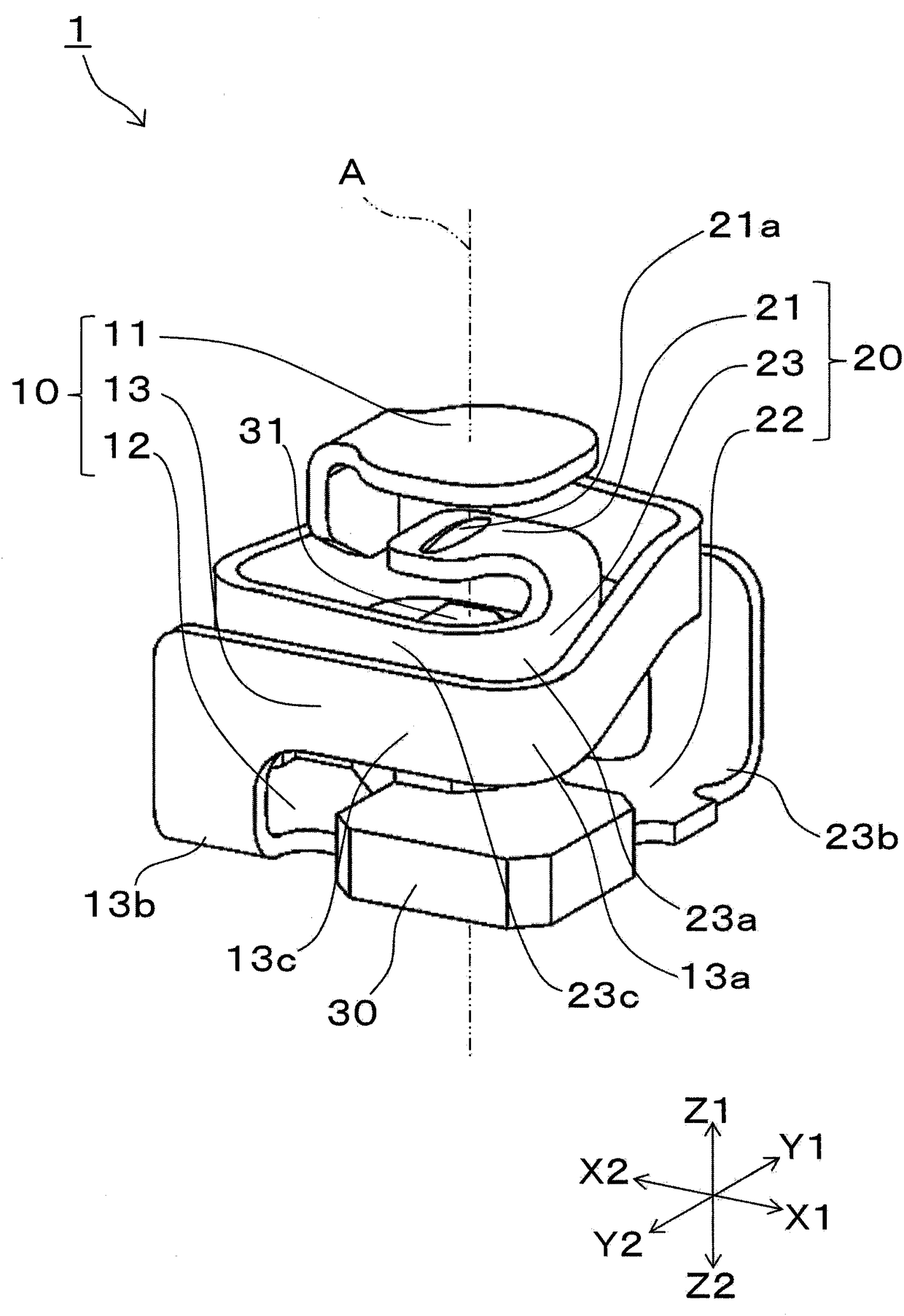

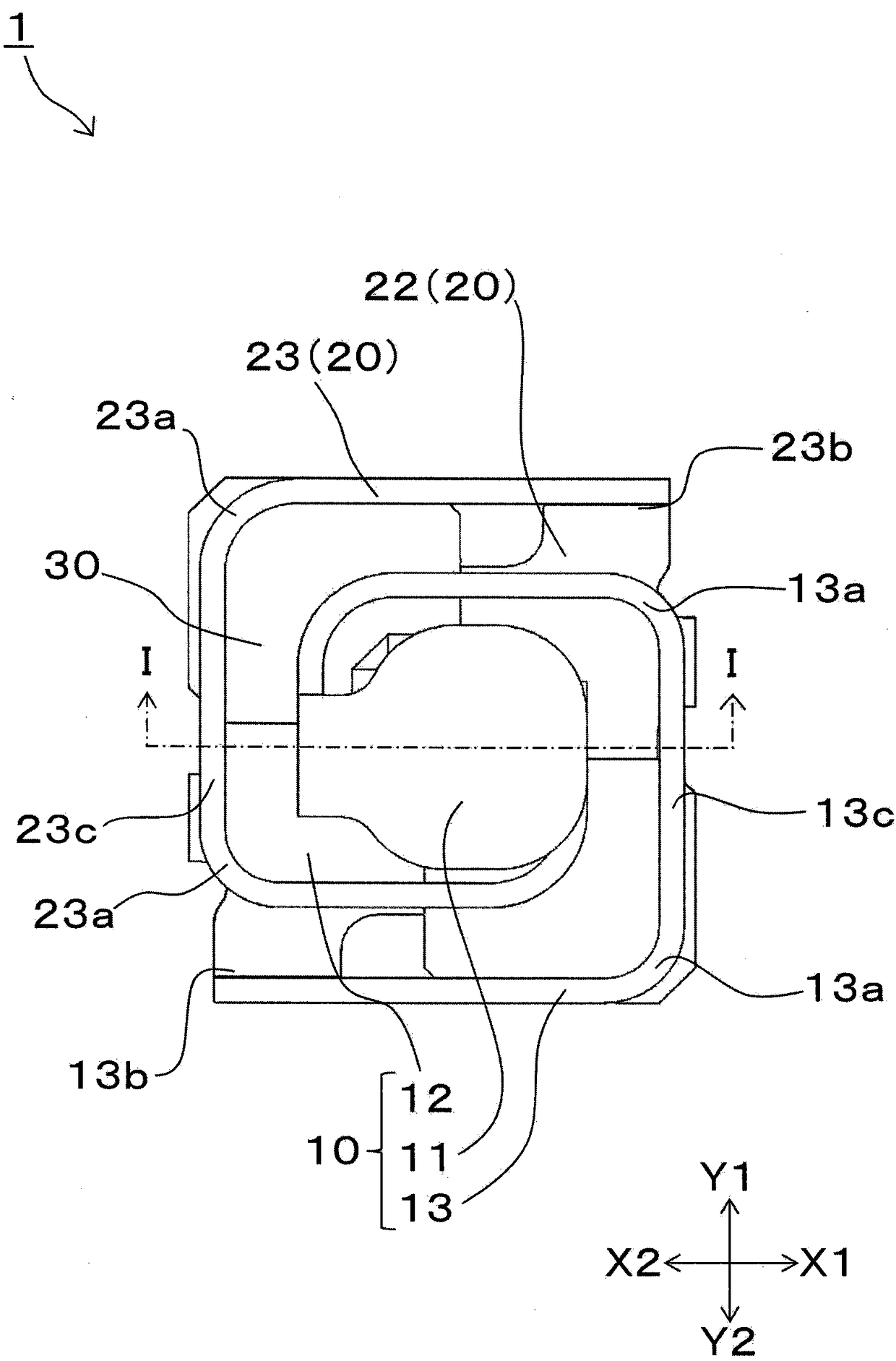

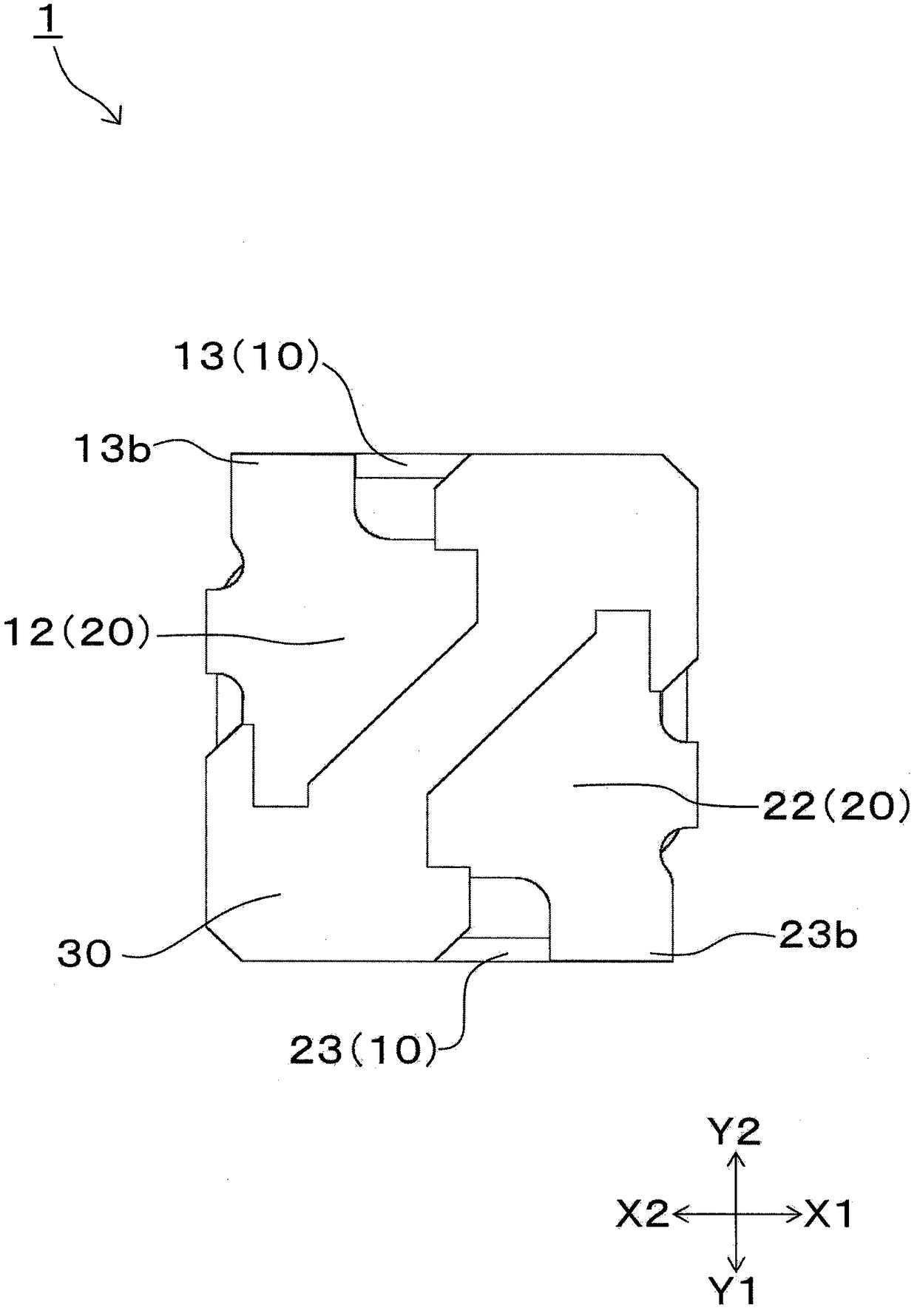

[0054] Below, use Figure 1 to Figure 6 The configuration of the switch device 1 according to the first embodiment of the present invention will be described. figure 1 It is a perspective view showing the switch device 1 according to the first embodiment of the present invention. figure 2 is viewed from above figure 1 The top view of the switching device 1 is shown. image 3 is viewed from below figure 1 Bottom view of the switchgear 1 shown. Figure 4 It is viewed from the Y2 direction figure 1 The side view of the switching device 1 is shown. Figure 5 is viewed from the Z1 direction along the Figure 4 The J-J line shown is a schematic cross-sectional view when the switch device 1 is cut through the first connecting portion 13 . Figure 6 is viewed from the Y2 direction along the figure 2 It is a schematic cross-sectional view of the switch device 1 in the non-pressing operation after the I-I line is shown.

[0055] It should be noted that, in order to explai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com