Skew-angle radius filler to reduce the risk of delamination of a laminated stringer assembly

A technology of inclination angle and radius, used in thin material processing, aircraft parts, chords/stringers, etc., can solve problems such as adding extra weight to aircraft, and achieve the effect of large operating load and enhanced joint ability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

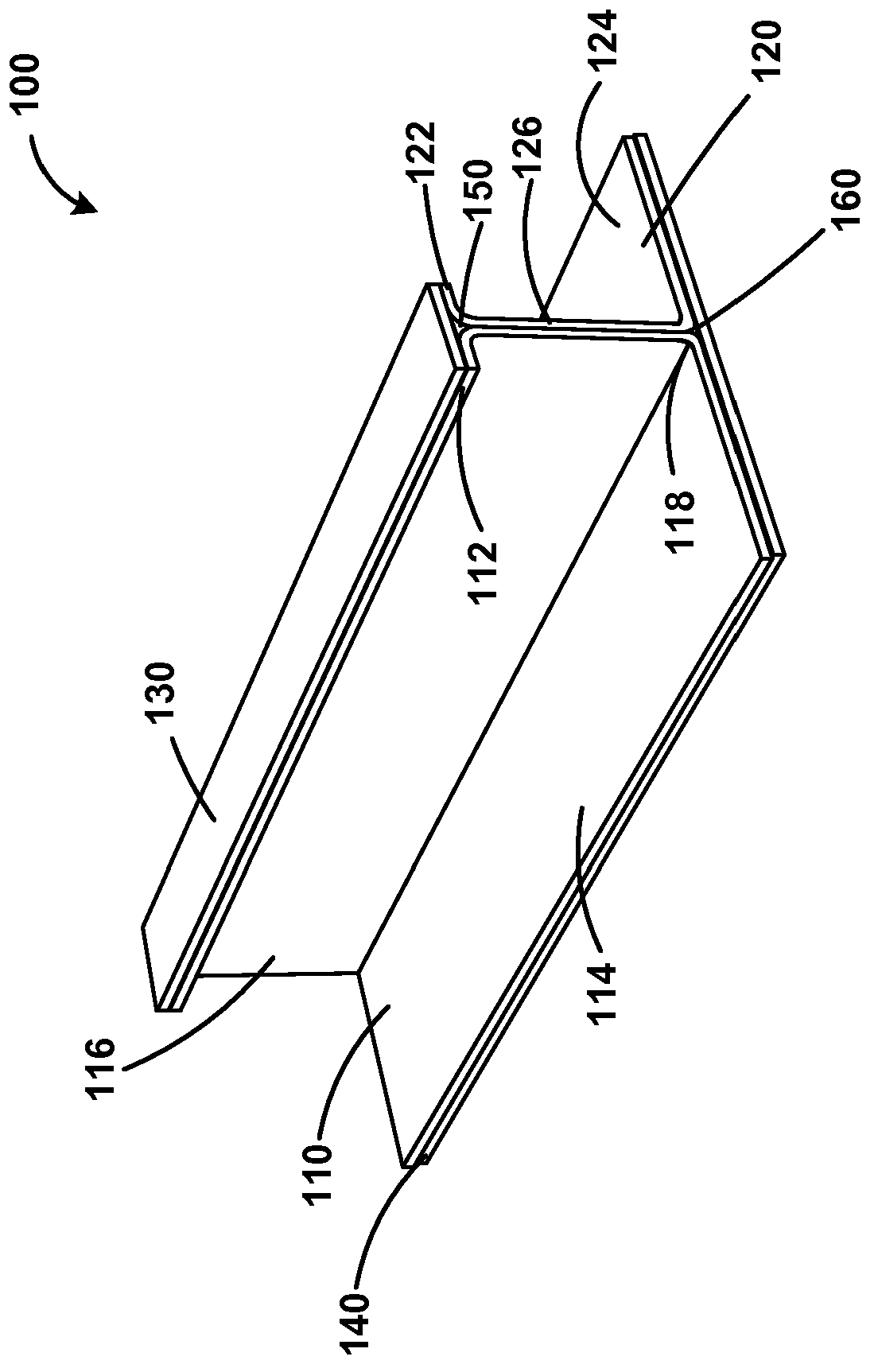

[0030] 本文描述了用于使用倾斜角半径填料增强接合能力和降低在桁条中分层的风险的技术。通过利用本文所呈现的技术和概念,与使用常规矩形半径填料的现有的桁条相比,所述桁条条形件可以通过使用倾斜角半径填料承受更大的平面外(引出)载荷,而不分层。

[0031] 在下面的具体实施方式中,参考构成特定实施例或示例的一部分并且以说明的方式示出的附图。现在参考附图,其中类似标记贯穿几个附图表示类似的元件,将描述用于使用根据各种实施例的倾斜角半径填料增强接合能力和降低蒙皮-桁条组件的分层风险的技术。

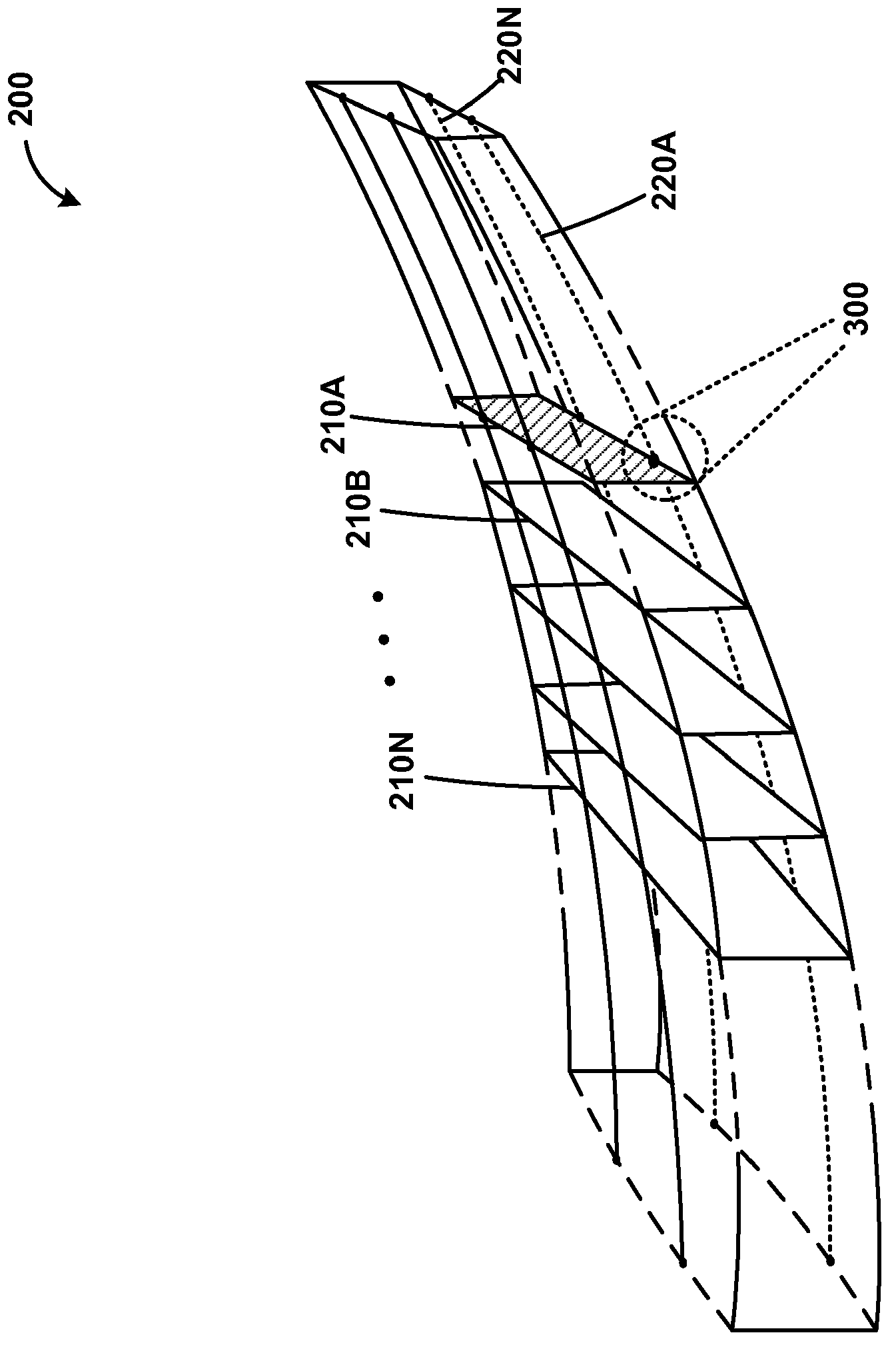

[0032] figure 2 示出了根据各种实施例的飞行器机翼的翼盒的透视图。翼盒200是飞行器机翼的结构核心,并提供了结构支撑以及对附连到机翼的各种飞行器部件的附连点。翼盒200可包括横跨翼盒200的跨度横向延伸的肋条区段210A、210B、210N。任何特定的肋条区段(如肋条区段210A)通常可在这里称为肋条区段210。肋条区段210可附连到沿翼盒200的跨度纵向延伸的多个桁条220A、220N。任何特定桁条(如桁条220A)通常可在这里称为桁条组件220。桁条组件220可用于向所述机翼的机翼蒙皮(figure 2 not shown) to provide additional stiffness. According to various embodiments, the wing skin may be attached to the stringer assembly forming a skin-stringer panel.

[0033] It should be understood that wing box 200 has been greatly simplified in the drawings for clarity. For example, the spars and all aircraft system components located in the wings are not shown. Furthermore, only a small number of representative rib segments 210 and stringer assemblies 220 are shown. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com