Production equipment and process of p-xylene

A technology for p-xylene and production equipment, which is applied in the purification/separation of hydrocarbons, organic chemistry, chemical instruments and methods, etc., and can solve the problem of increasing the fuel consumption of xylene reboiler, increasing the operating load and cooling load of xylene tower Large and other problems, to achieve the effect of reducing back-mixing, saving condensation and reboiling load, and large cooling load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

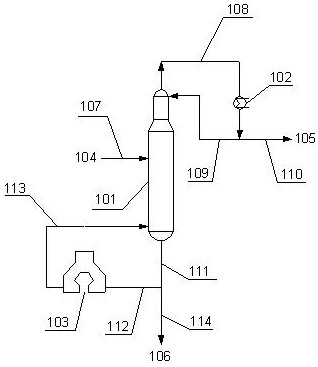

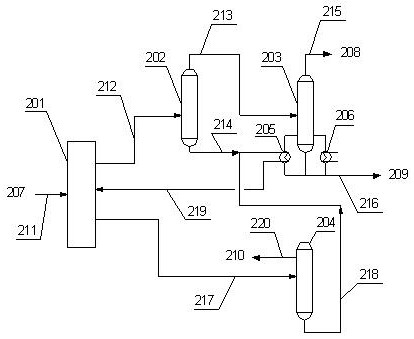

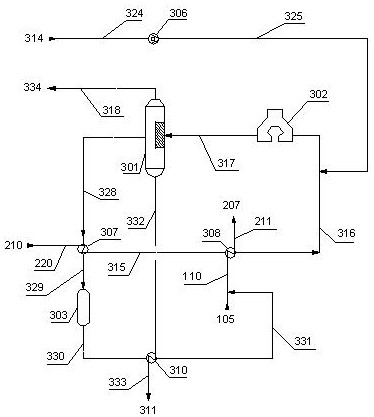

Method used

Image

Examples

Embodiment 1

[0065] Embodiment 1 illustrates the method and energy consumption of the novel p-xylene production process provided by the present invention, wherein the isomerization reaction rectification overhead product directly leaves the device without separation, and the hydrogen required for the isomerization reaction is boosted by a compressor Afterwards, it is mixed with the isomerization reaction feed. The energy consumption of the device is shown in Table 2.

[0066] Table 1

[0067]

[0068] Table 2

[0069]

[0070] It can be seen from Table 1 and Table 2 that compared with Comparative Example 1, the method for producing p-xylene provided by the present invention can save the investment of a separate isomerization reactor, gas-liquid separation tank and air cooler. Adopting the method provided by the invention not only reduces the number of equipment, but also reduces energy consumption by 19.3%. Therefore, adopting the novel p-xylene production method provided by the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com