Infrared gas heating or infrared gas heating and electric heating combined module furnace

A technology of gas heating and electric heating, which is applied to water heaters, fluid heaters, lighting and heating equipment, etc., to achieve the effect of reducing gas consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

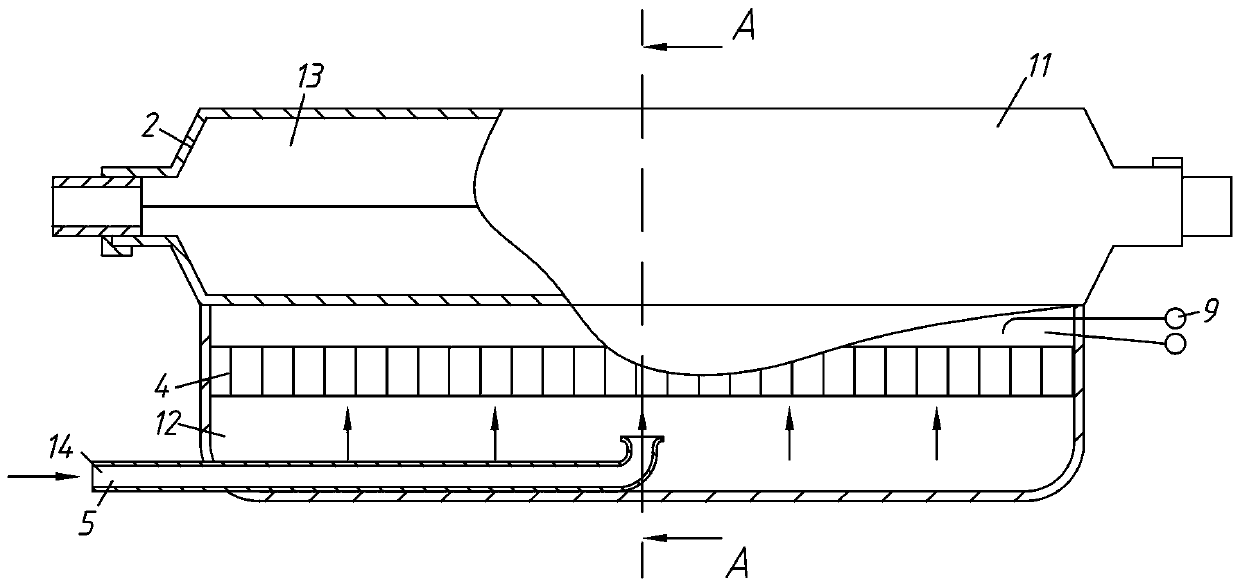

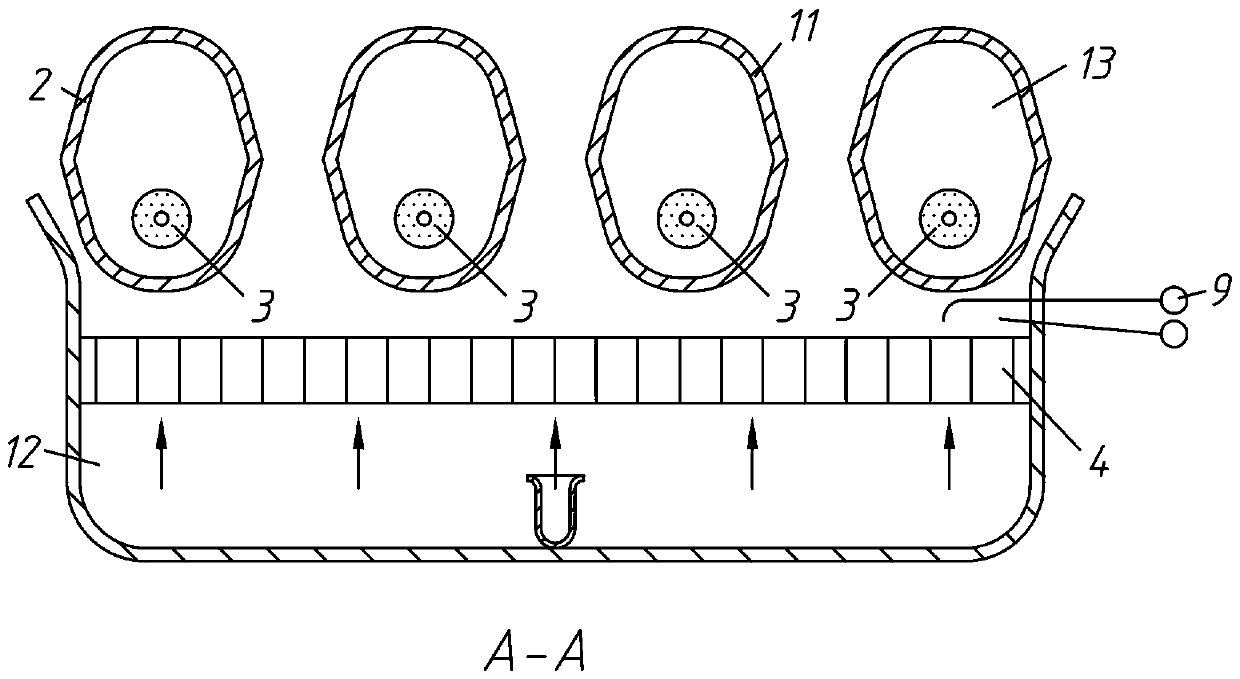

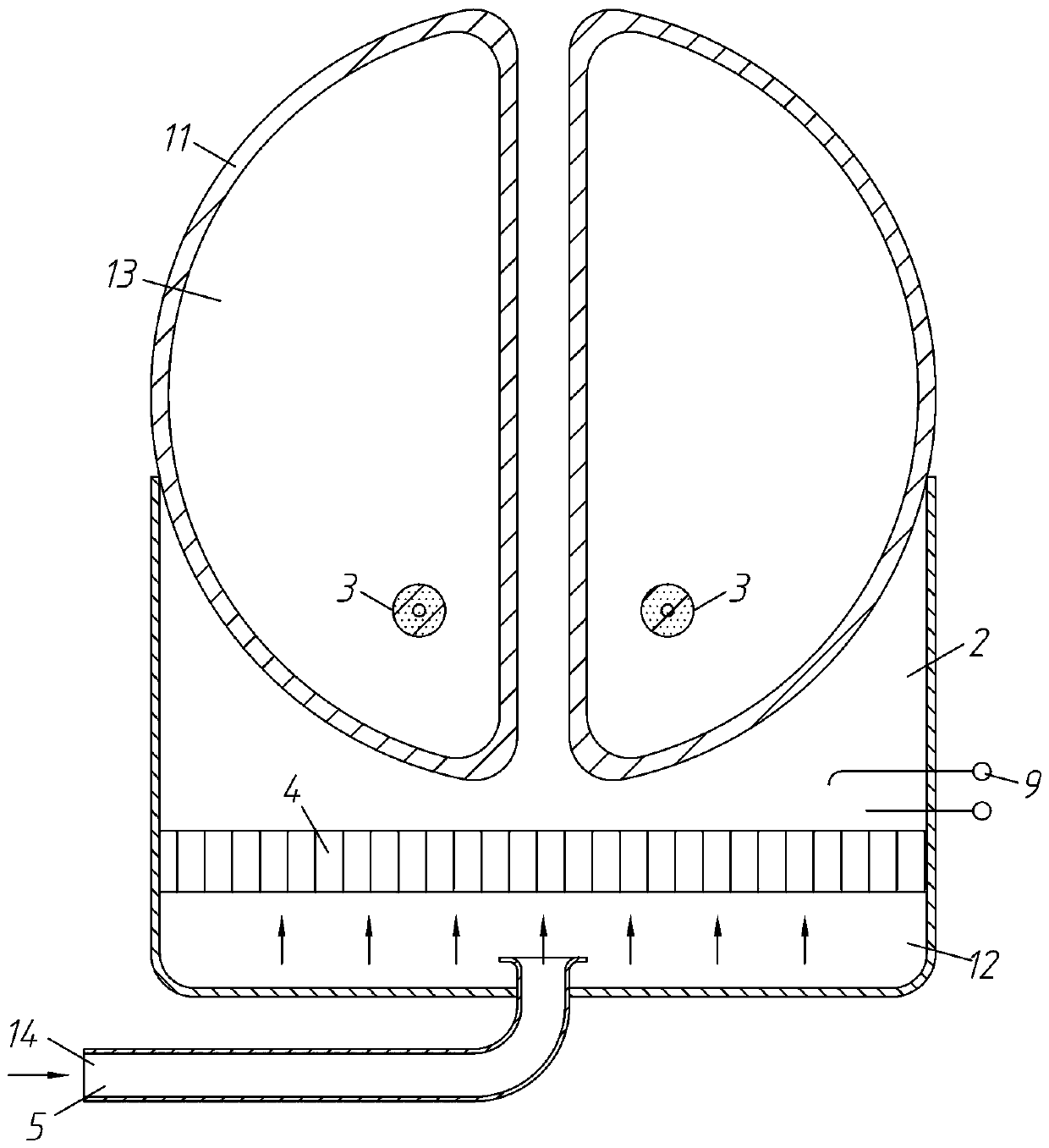

[0013] The following will be described in conjunction with the accompanying drawings. In the accompanying drawings, the shell 1, the infrared burner 2, the electric heating tube 3 (fast heating electric heating tube 3-1, heating electric heating tube 3-2), metal or non-metallic ceramic honeycomb plate 4, primary premixed Air inlet 5, fan 5-1, heating return pipe 6, hot water outlet pipe (or mouth) 7, magnetic water switch or water flow sensor 8, water pump 9, gas valve 10, heat exchange water container or water tank 11 for short (including high temperature Water tank 11-1 and low temperature water tank 11-2, domestic hot water tank 11-3), gas mixing chamber 12, water 13, gas inlet 14, exhaust duct 15, compressible air 16, tap water pipe 17, mechanical Or electronic controller 18, ignition needle and flameout protection device 19, temperature limit switch 20, compressible air 21, coil pipe 22, flange 32, three-way mixing valve 33, domestic water point 34, pressure relief and dra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com