Condensate water prevention gas water heater and control method

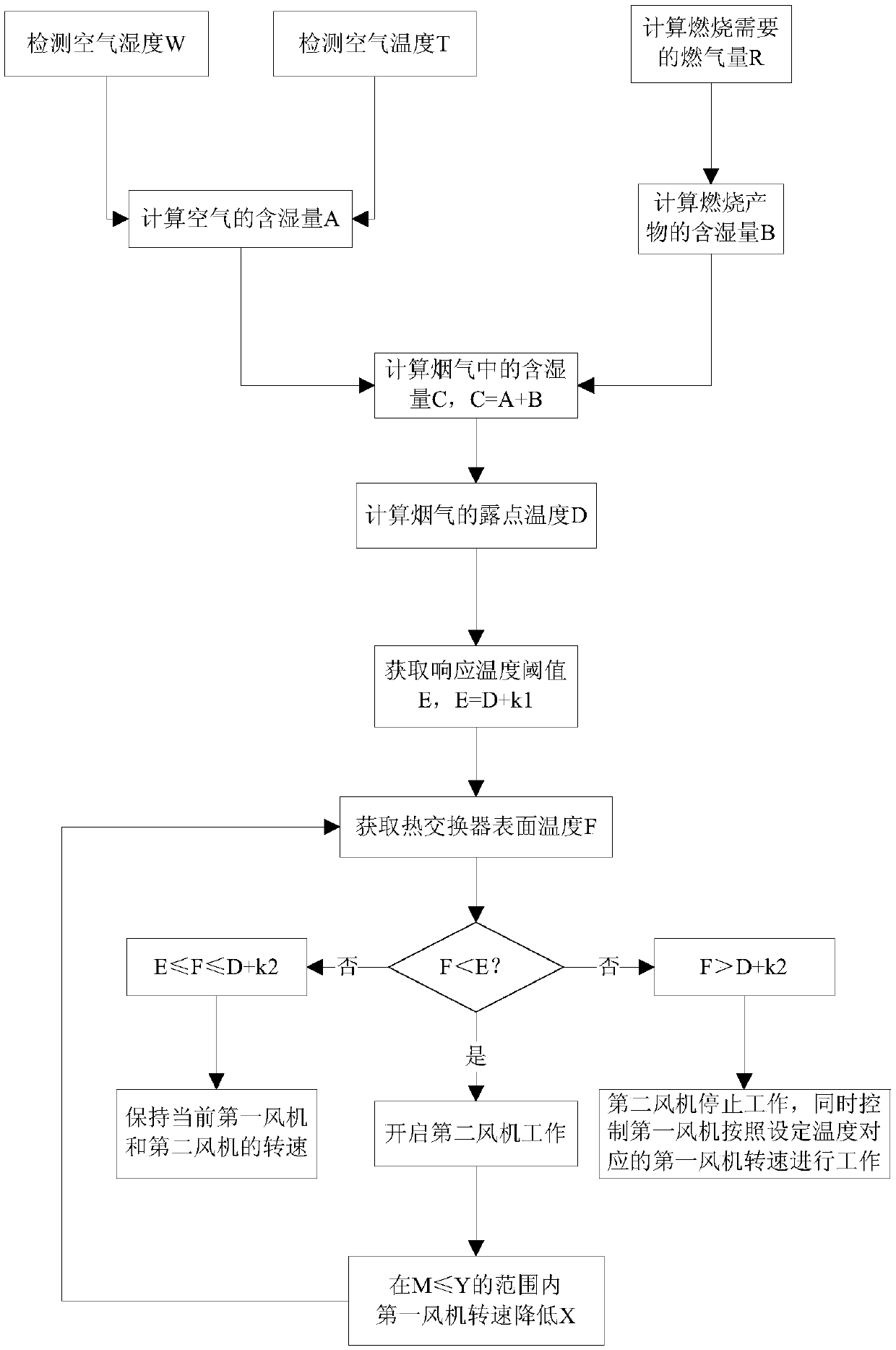

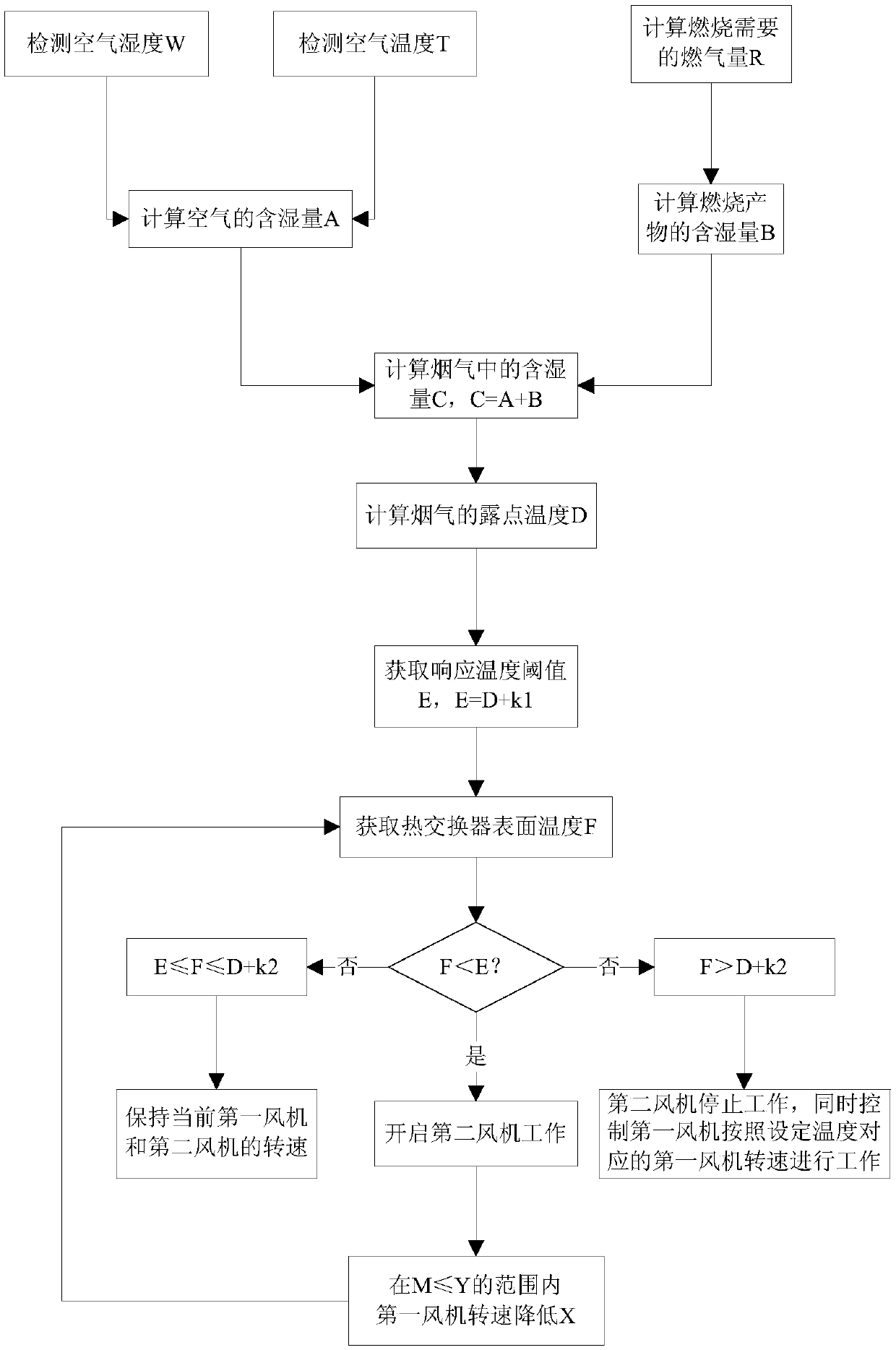

A gas water heater, anti-condensation technology, applied in water heaters, fluid heaters, lighting and heating equipment, etc., can solve the problems of gas consumption, high air humidity, high computing load, reduce dew point temperature, reduce Moisture content, effect of preventing condensation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

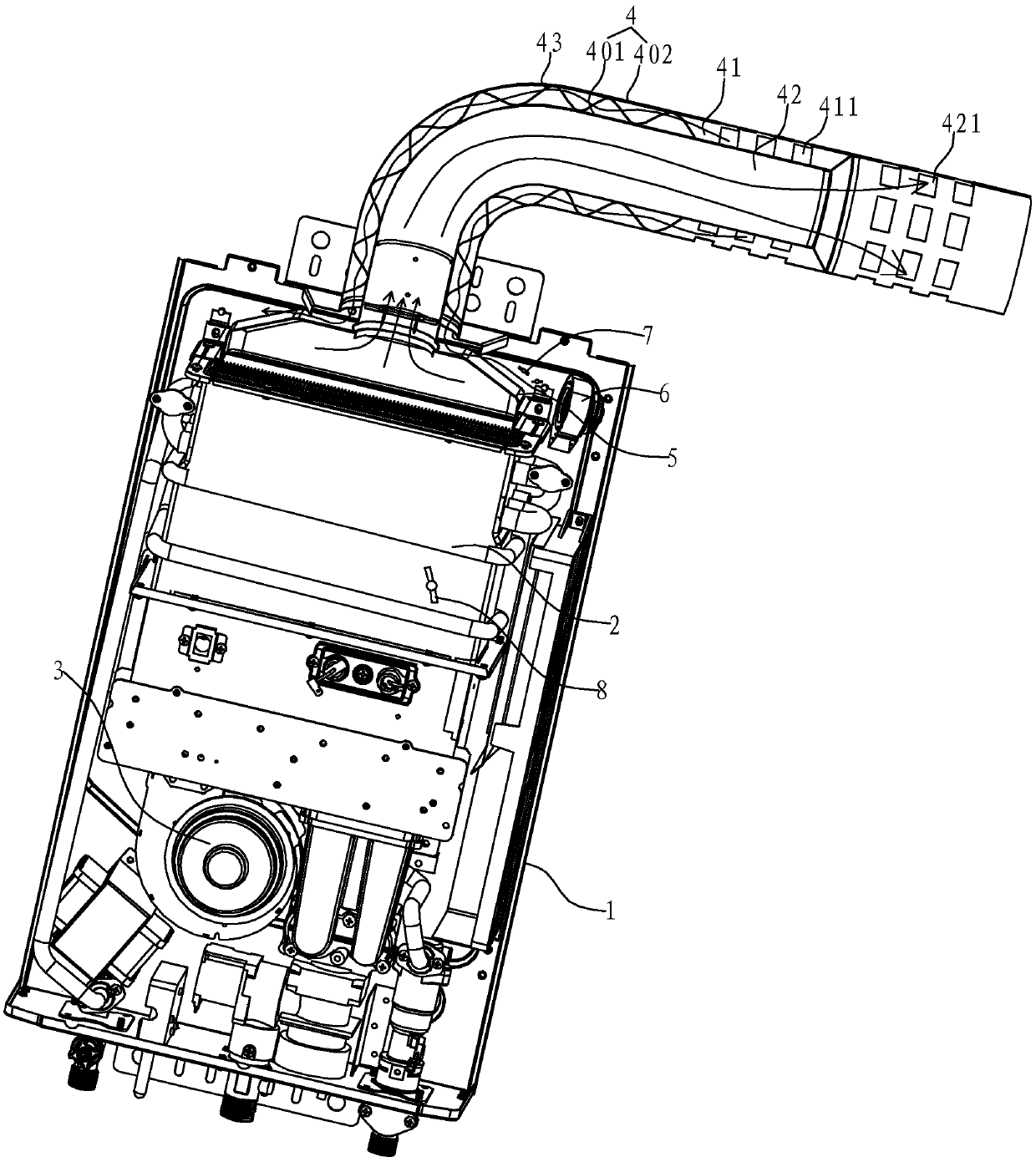

[0038] Such as figure 1 As shown, the anti-condensation gas water heater in this embodiment includes a housing 1 , a heat exchanger 2 , a first fan 3 , a ventilation pipe 4 , a second fan 6 , a temperature and humidity sensor 7 , and a temperature sensor 8 .

[0039] The heat exchanger 2 is arranged in the casing 1, the first fan 3 is arranged in the casing 1, and the air outlet of the first fan 3 is connected with the air inlet of the combustion chamber in the casing 1, by adjusting the first The speed of the fan 3 can control the amount of air entering the combustion chamber. In order to ensure normal combustion, the first fan 3 is usually set with a minimum speed threshold.

[0040] The ventilation pipe 4 is connected to the casing 1 , and the ventilation pipe 4 is connected to the top of the casing 1 in this embodiment. The ventilation p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com