A highly-wear-resistant thermoplastic polyurethane elastomer and a preparing method thereof

A thermoplastic polyurethane and elastomer technology, applied in the field of polyurethane, can solve problems such as affecting product processing, long injection molding cycle of polyurethane elastomer, affecting product use, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

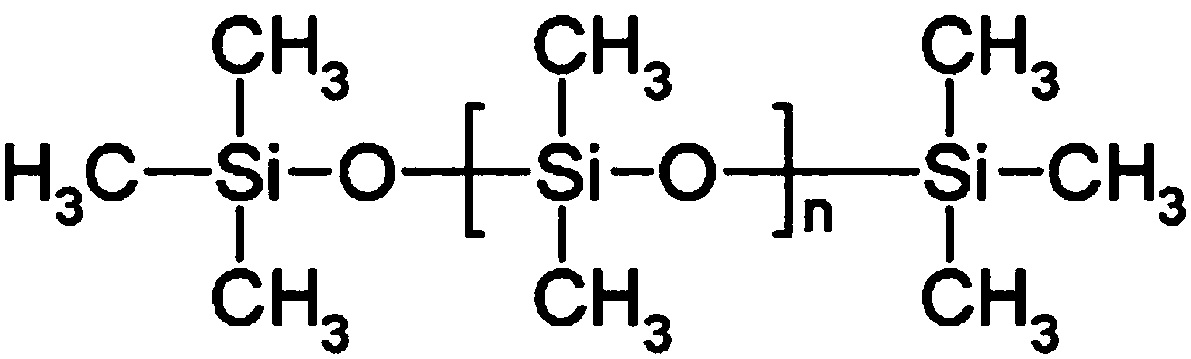

[0022] Preparation of the mixture of polyester diol and 1,4-butanediol: mix polyester diol and 1,4-butanediol at a ratio of 100:15, add 5‰ silicone oil, and stir thoroughly at 80-90°C for 0.5 -1 hour to obtain a mixture of polyester diol and 1,4-butanediol. The silicone oil is a linear non-reactive polydimethylsiloxane with a molecular weight between 7000-12000 and a molecular structure as follows:

[0023]

[0024] The polyester polyol is polyethylene adipate-1,4-butylene glycol ester diol; the molecular weight is 2000-3000.

[0025] Add 50% of the weight of the mixture of 4,4'-diphenylmethane diisocyanate and 0.06‰ of the catalyst stannous octoate to the mixture of polyester diol and 1,4-butanediol, fully stir the reaction, the initial reaction temperature After aging for 60 hours at 80°C, it is crushed and granulated by a granulator to obtain a polyurethane elastomer with a Shore hardness of 90A-64D.

[0026] Mix polyurethane elastomer with 4‰ of silicone masterbatch, ...

specific Embodiment 2

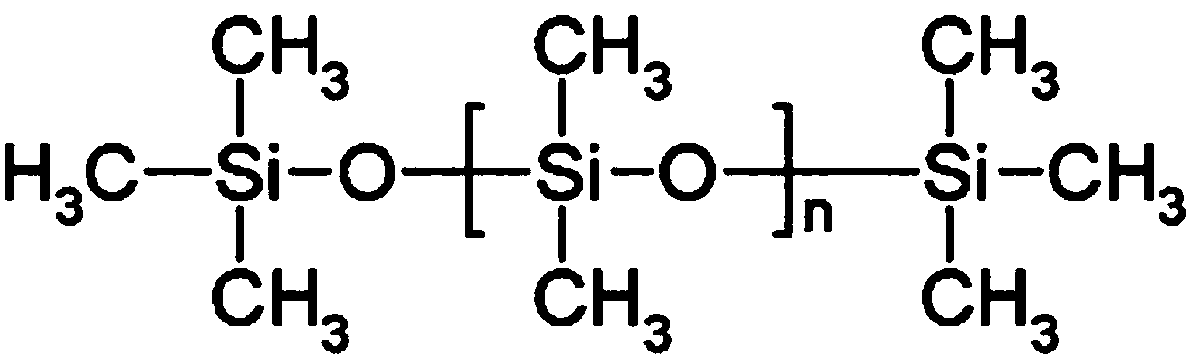

[0027] Preparation of the mixture of polyester diol and 1,4-butanediol: mix polyester diol and 1,4-butanediol at a ratio of 100:40, add 5‰ silicone oil, and stir thoroughly at 80-90°C for 1 Hours, a mixture of polyester diol and 1,4-butanediol was obtained. The silicone oil is a linear non-reactive polydimethylsiloxane with a molecular weight between 7000-12000 and a molecular structure as follows:

[0028]

[0029] The polyester polyol is polyethylene adipate-1,4-butylene glycol ester diol; the molecular weight is 2000-3000.

[0030] Add 90% of the weight of the mixture of 4,4'-diphenylmethane diisocyanate and 0.06‰ of the catalyst stannous octoate to the mixture of polyester diol and 1,4-butanediol, fully stir the reaction, the initial reaction temperature After aging at 85°C for 70 hours, it is crushed and granulated by a granulator to obtain a polyurethane elastomer with a Shore hardness of 90A-64D.

[0031] Mix polyurethane elastomer with 5‰ silicone masterbatch, bak...

specific Embodiment 3

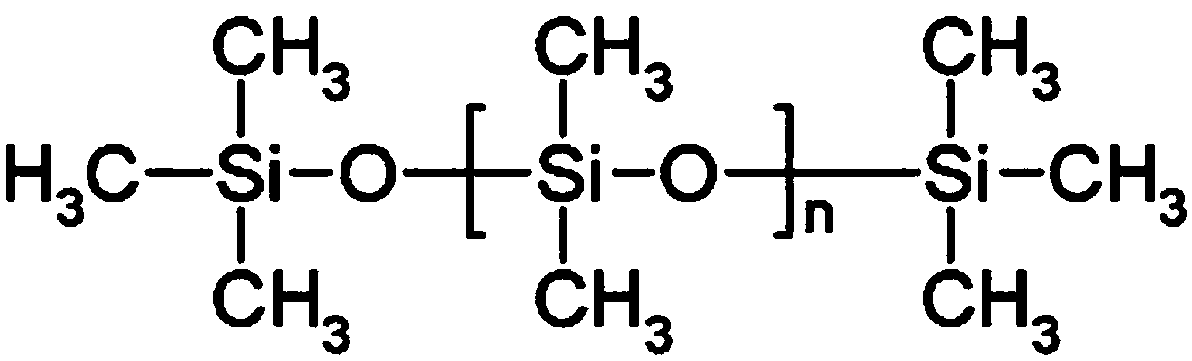

[0032] Preparation of the mixture of polyester diol and 1,4-butanediol: mix polyester diol and 1,4-butanediol at a ratio of 100:30, add 7‰ silicone oil, and stir thoroughly at 80-90°C for 1 Hours, a mixture of polyester diol and 1,4-butanediol was obtained. The silicone oil is a linear non-reactive polydimethylsiloxane with a molecular weight between 7000-12000 and a molecular structure as follows:

[0033]

[0034] The polyester polyol is polyethylene adipate-1,4-butylene glycol ester diol; the molecular weight is 2000-3000.

[0035] Add 70% of the weight of the mixture of 4,4'-diphenylmethane diisocyanate and 0.04‰ of the catalyst stannous octoate to the mixture of polyester diol and 1,4-butanediol, fully stir the reaction, the initial reaction temperature After aging at 85°C for 70 hours, it is crushed and granulated by a granulator to obtain a polyurethane elastomer with a Shore hardness of 90A-64D.

[0036] Mix polyurethane elastomer with 5‰ silicone masterbatch, bak...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shore hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com