A kind of chemical condenser and method for using it to condense and separate gas phase products

A condensation separation and condenser technology, applied in separation methods, chemical instruments and methods, vapor condensation, etc., can solve problems such as reducing heat transfer coefficient, affecting condensation effect, affecting reaction effect, etc., to reduce solubility, improve condensation efficiency, The effect of reducing the condensing load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

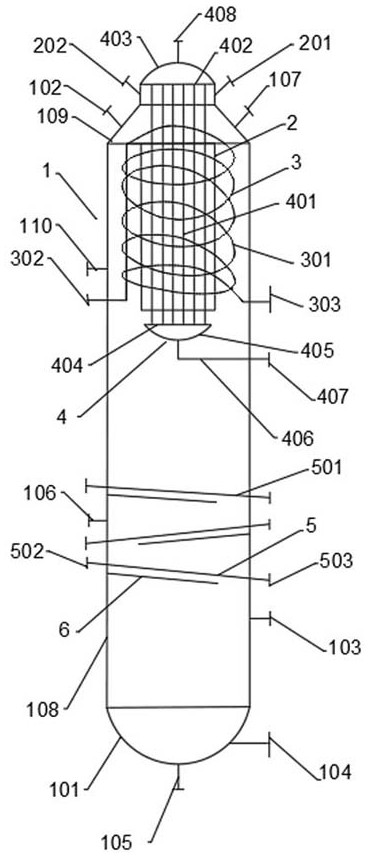

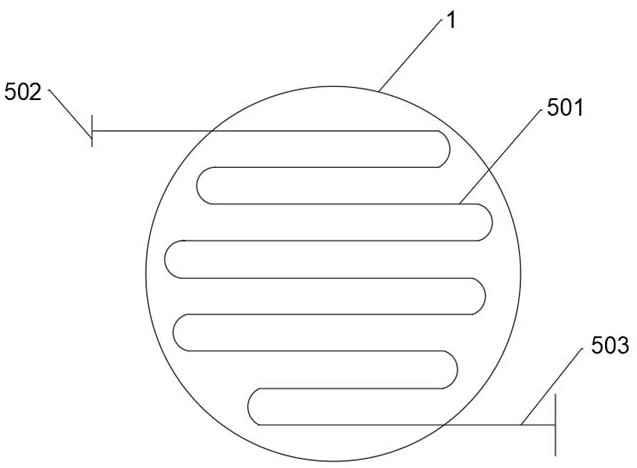

[0035] Such as Figure 1-5 As shown, the embodiment of the present invention provides a chemical condenser, including an outer cylinder 1, an inner isolation cylinder 2, a coil condenser 3, an exposed tube condenser 4, a coil heater 5 and a film-forming plate 6; the outer cylinder 1. It consists of an outer cylinder body 108, an outer cylinder upper head 109 and an outer cylinder lower head 101. The upper part of the outer cylinder body 108 is a condensation area, and the lower part is a separation area; the inner isolation cylinder 2 runs through the upper part of the outer cylinder 1 Extending to the inside of the outer cylinder 1 and connected to the upper head 109 of the outer cylinder, the outer side of the inner isolation cylinder 2 is the primary cooling zone, and the inside is the deep cooling zone; the coil condenser 3 is located inside the primary cooling zone and is composed of condensing coils 301 The bare tube condenser 4 is made up of the condensing tube 401, the...

Embodiment 2

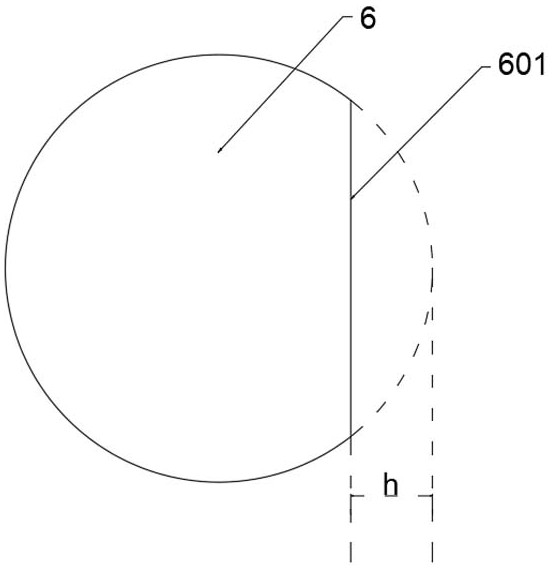

[0051] The condensing separator of this embodiment is the same as that of Embodiment 1. The difference between this embodiment and Embodiment 1 is that: the coil heater 5 is closely attached to the top of the film-forming plate 6 and is located 600 mm below the bottom head 405 of the condensation tube. , the angle between the coil heater 5 and the outer cylinder 108 is equal to the angle α between the film-forming plate 6 and the outer cylinder 108, and the angle α is 92°. Three coil heaters, 3 film-forming plates, the film-forming plate 6 is a circular plate with a diameter equal to the diameter of the outer cylinder body 108, and a part of the inferior circle is cut off, and the maximum linear distance h between the cut-off inferior circle arc and the chord is the cylinder body 4 / 15 of the diameter; the minimum distance g between two adjacent film-forming plates 6 is equal to h, and the upper interface 103 of the liquid level gauge is located at 600 mm below the film-forming ...

Embodiment 3

[0055] The condensing separator of this embodiment is the same as that of Embodiment 1, and the difference from Embodiment 1 is that: the coil heater 5 is closely attached to the top of the film-forming plate 6, and is located at 1000mmc below the lower head 405 of the condensing tube, and the film-forming plate The included angle α between 6 and the outer cylinder body 108 is 95°, 5 coil heaters, 5 film-forming plates, and the maximum linear distance h between the inferior circle cut off by the film-forming plate 6 and the chord is 1 / 3 of the cylinder diameter; the minimum distance g between two adjacent film-forming plates 6 is equal to h; the upper interface 103 of the liquid level gauge is located at 1000 mm below the film-forming plates 6 .

[0056] The method of using the above-mentioned condensing separator to condense and separate urea and ethylene glycol to react to prepare a gas mixture with a discharge temperature of 140°C from the ethylene carbonate reactor is the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com