Comprehensive water-saving and energy-saving system for generator sets

A technology for generator sets and energy-saving systems, which is applied in the direction of machines using waste heat, machine operation methods, and climate change adaptation. It can solve problems such as high load of decompression equipment, large difference in specific gravity, and impact on heat exchange efficiency, and achieve condensation load. Reduce and highlight the effect of energy saving and high heat exchange efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

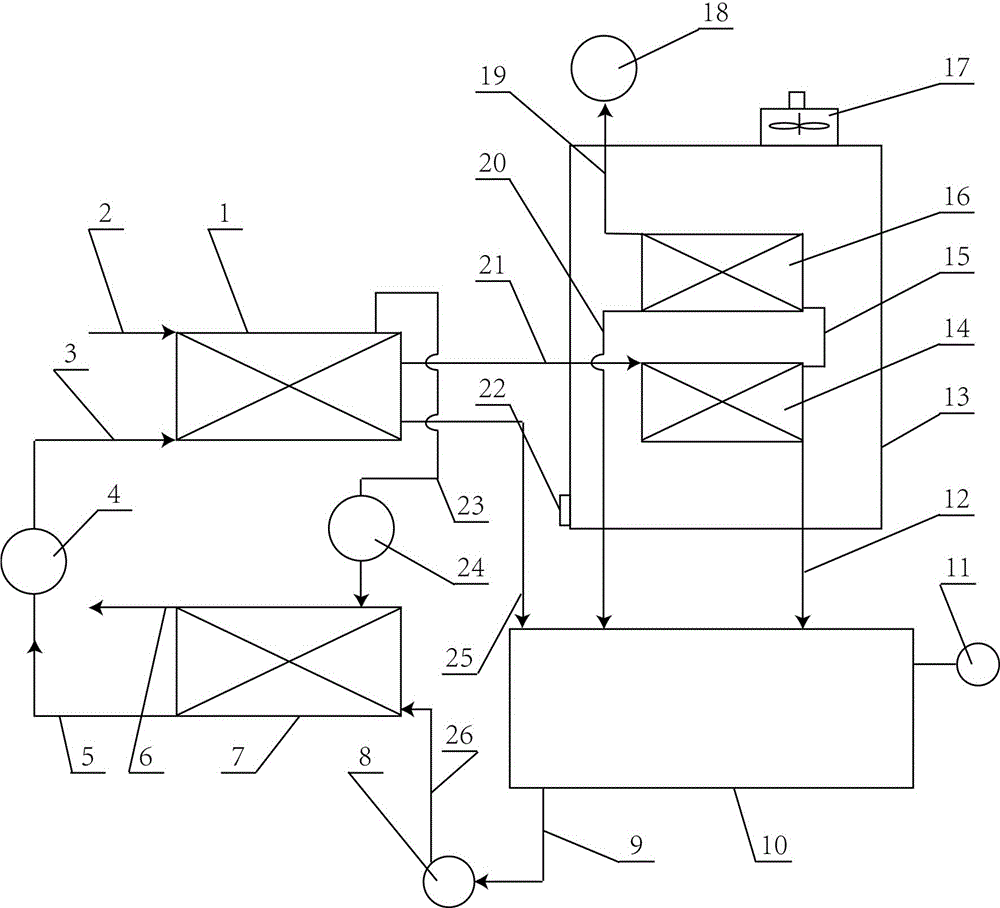

[0024] Such as figure 1 As shown, this embodiment includes a first heat exchanger 1 and a second heat exchanger 7, the intake end of the first heat exchanger 1 is connected with a exhaust steam inlet pipe 2, and the refrigerant outlet of the first heat exchanger 1 A compressor 24 is connected through a refrigerant air pipe 23, the exhaust end of the compressor 24 is connected to the refrigerant inlet of the second heat exchanger 7, and the refrigerant outlet of the second heat exchanger 7 is connected to a joint through the refrigerant A liquid pipe 5. The flow valve 4 and the throttle valve 4 are connected to the refrigerant inlet of the first heat exchanger 1 through the refrigerant B liquid pipe 3 .

[0025] The liquid discharge end of the first heat exchanger 1 is connected with the liquid storage tank 10 through the liquid discharge pipe 25, and also can not set the liquid discharge pipe 25 when the liquid discharge amount of the first heat exchanger 1 is less, the first ...

Embodiment 2

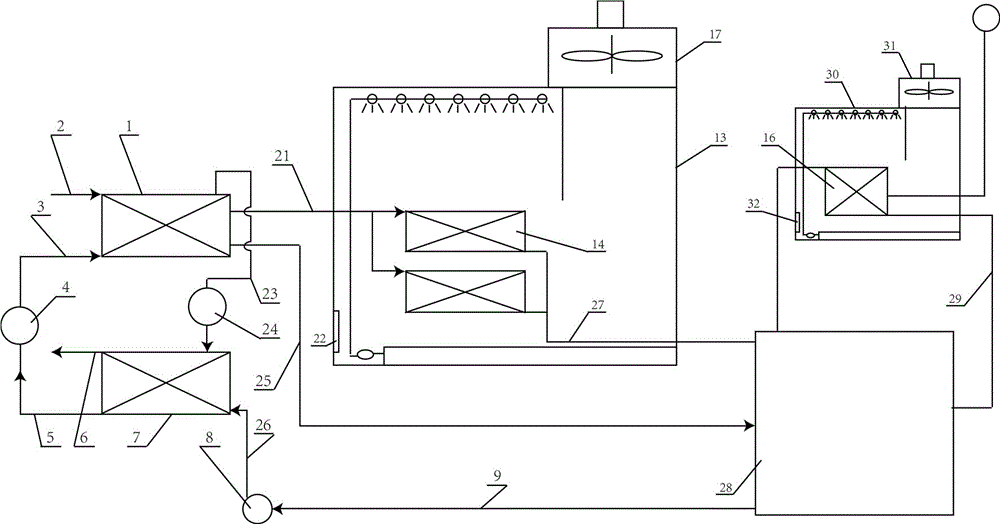

[0035] Such as figure 2 As shown, this embodiment includes a first heat exchanger 1 and a second heat exchanger 7, the intake end of the first heat exchanger 1 is connected with a exhaust steam inlet pipe 2, and the refrigerant outlet of the first heat exchanger 1 A compressor 24 is connected through a refrigerant air pipe 23, the exhaust end of the compressor 24 is connected to the refrigerant inlet of the second heat exchanger 7, and the refrigerant outlet of the second heat exchanger 7 is connected to a joint through the refrigerant A liquid pipe 5. The flow valve 4 and the throttle valve 4 are connected to the refrigerant inlet of the first heat exchanger 1 through the refrigerant B liquid pipe 3 . The liquid discharge end of the first heat exchanger 1 is connected with a liquid reservoir 28 through a liquid discharge pipe 25. When the liquid discharge of the first heat exchanger 1 is less, the liquid discharge pipe 25 may not be set. The first heat exchanger 1 The disch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com