A kind of continuous rectification separation method and device of propylene carbonate crude product

A technology for propylene carbonate and rectification separation, which is applied in separation methods, distillation separation, chemical instruments and methods, etc., can solve the problems of high operating costs, difficulty in meeting battery-level purity requirements, etc., achieves multiple gas-liquid contact spaces, improves Mass transfer and separation efficiency, the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

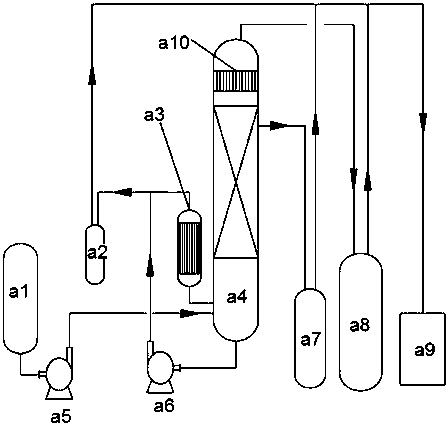

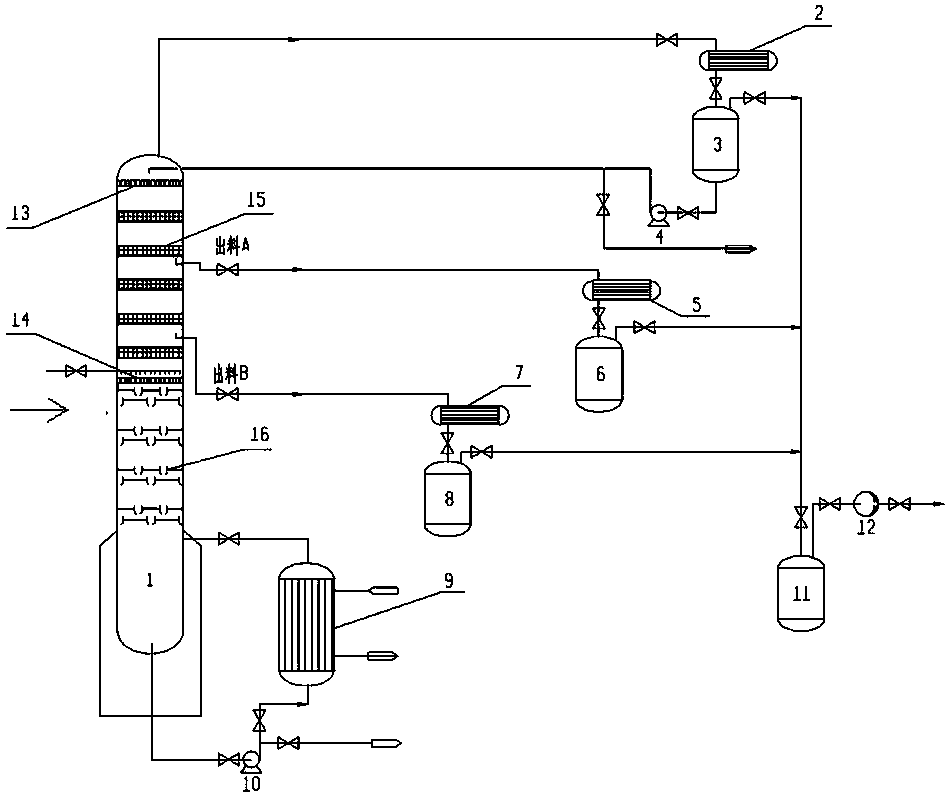

[0034] Embodiment 1: with reference to attached figure 2 , the continuous rectification separation method of a kind of propylene carbonate crude product that the present invention mentions, its technical scheme is to comprise the following steps:

[0035] Step 1: The operating temperature is 90-130°C, and the crude propylene carbonate product with a product purity of 98% enters the middle part of the propylene carbonate rectification tower 1, and the inner cavity of the propylene carbonate rectification tower 1 is provided with a reflux distributor from top to bottom 13. Multiple groups of diamond-shaped reaction promotion units 15, feed distributor 14 and multiple groups of liquid stripping filter discs 16, the outside of the propylene carbonate rectifying tower 1 are respectively connected to the rectifying tower top condenser 2 and the A discharge line condenser 5. B discharge line condenser 7 and rectification column kettle reboiler 9;

[0036] Step 2: After sufficient g...

Embodiment 2

[0046] Embodiment 2: the continuous rectification separation method of a kind of propylene carbonate crude product that the present invention mentions, its technical scheme is to comprise the following steps:

[0047] Step 1: the operating temperature is 90°C, and the propylene carbonate crude product with a product purity of 98% enters the middle part of the propylene carbonate rectification tower 1, and the inner cavity of the propylene carbonate rectification tower 1 is provided with a reflux distributor 13, Multiple groups of diamond-shaped reaction promotion units 15, feed distributors 14 and multiple groups of liquid stripping filter discs 16, the outside of the propylene carbonate rectifying tower 1 are respectively connected to the rectifying tower top condenser 2, the A discharge line condenser 5, B discharge line condenser 7 and rectifying column kettle reboiler 9;

[0048] Step 2: After sufficient gas-liquid exchange in the diamond-shaped reaction promotion unit 15 ...

Embodiment 3

[0052] Embodiment 3: the continuous rectification separation method of a kind of propylene carbonate crude product that the present invention mentions, its technical scheme is to comprise the following steps:

[0053] Step 1: the operating temperature is 130°C, and the propylene carbonate crude product with a product purity of 98% enters the middle part of the propylene carbonate rectification tower 1, and the inner cavity of the propylene carbonate rectification tower 1 is provided with a reflux distributor 13, Multiple groups of diamond-shaped reaction promotion units 15, feed distributors 14 and multiple groups of liquid stripping filter discs 16, the outside of the propylene carbonate rectifying tower 1 are respectively connected to the rectifying tower top condenser 2, the A discharge line condenser 5, B discharge line condenser 7 and rectifying column kettle reboiler 9;

[0054] Step 2: After sufficient gas-liquid exchange in the diamond-shaped reaction promotion unit 15...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com