Circulating working medium heat exchanger with oil separation function and application thereof

A circulating working fluid and oil separation technology, which is applied in the direction of machines/engines, steam turbines, mechanical equipment, etc., can solve problems such as the inability to monitor the concentration and temperature of lubricating oil, the low lubricating effect, and the large space occupied by equipment. , to achieve the effect of lowering the temperature, compact structure and saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

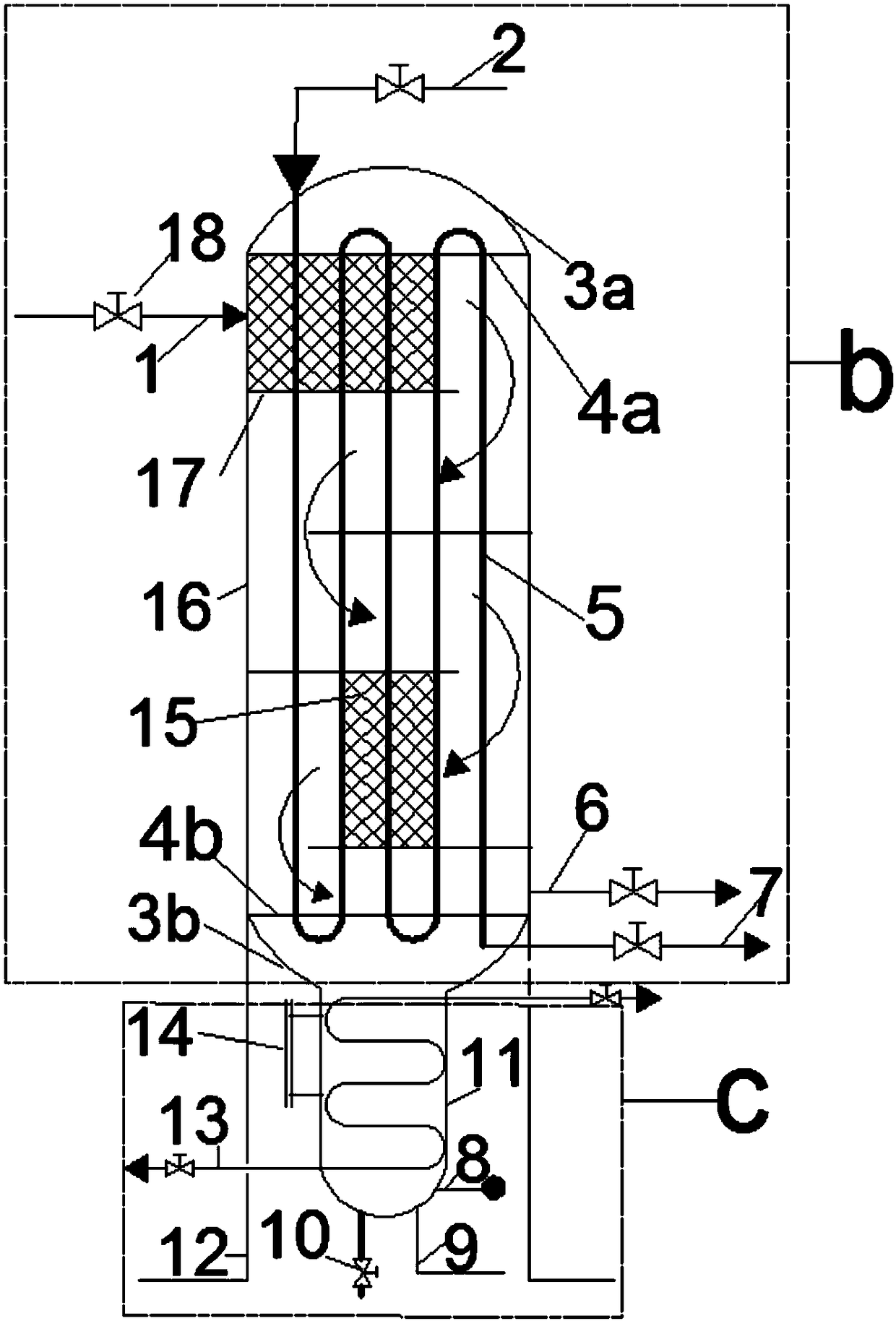

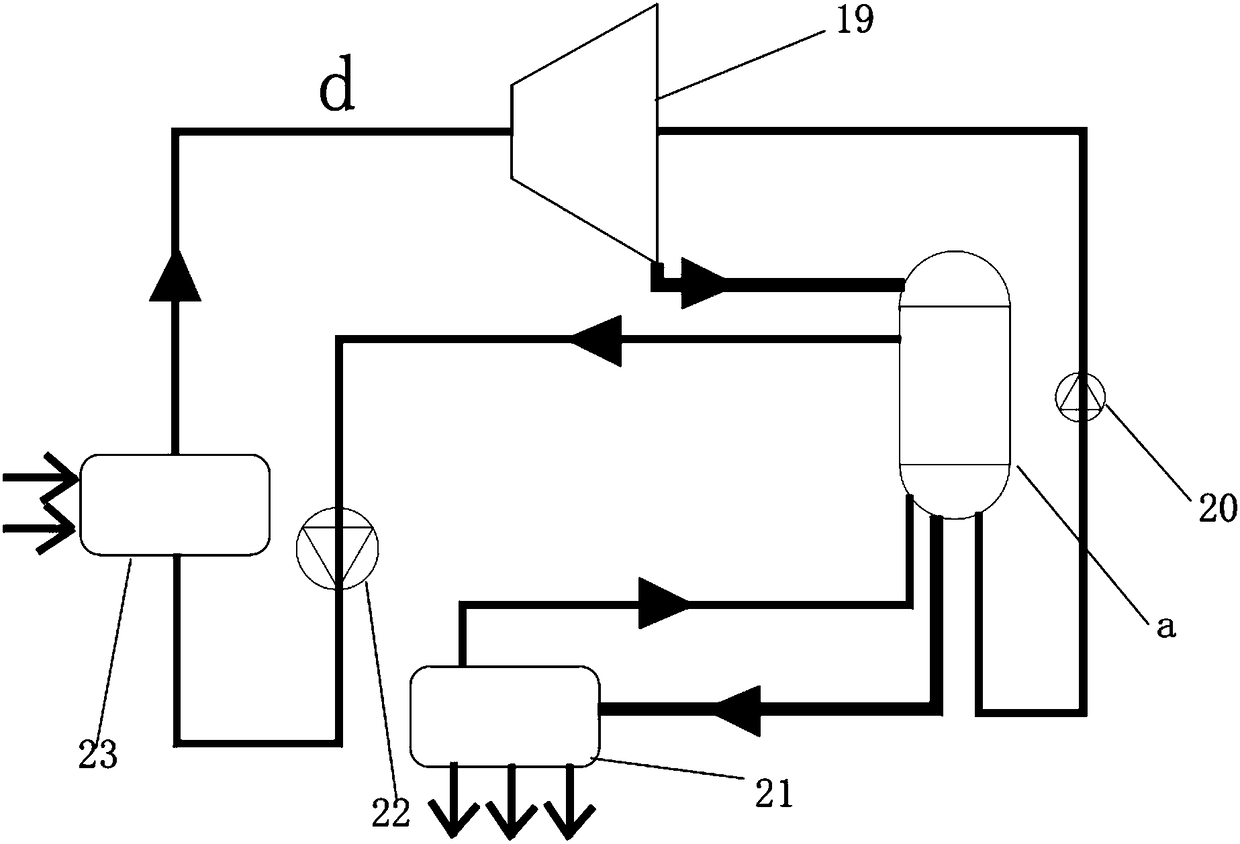

[0035] A circulating working medium heat exchanger with oil separation function includes an oil separation heat exchange device b and a heat exchange oil storage device c, the oil separation heat exchange device b is placed above the heat exchange oil storage device c and the two In the same way, the oil separation and heat exchange device b uses the liquid-phase working fluid to recover waste heat from the gas-phase working fluid and at the same time separates the lubricating oil mixed in the gas-phase working fluid, and the heat exchange and oil storage device c stores the separated lubricating oil and has the function of exchanging The heat exchange tube 13 of the thermal oil storage device has the effect of heating and cooling the lubricating oil;

[0036] The oil separation heat exchange device b includes a shell 16, and an upper tube plate 4a and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com