Internal energy integrated rectification device and rectification method using same

An internal energy and rectification technology, applied in the field of rectification, can solve the problems of underutilization of the heat of the rectification tower and low separation efficiency of the rectification tower, and achieve the improvement of the heat utilization rate, the separation efficiency and the reduction of the effective energy loss. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

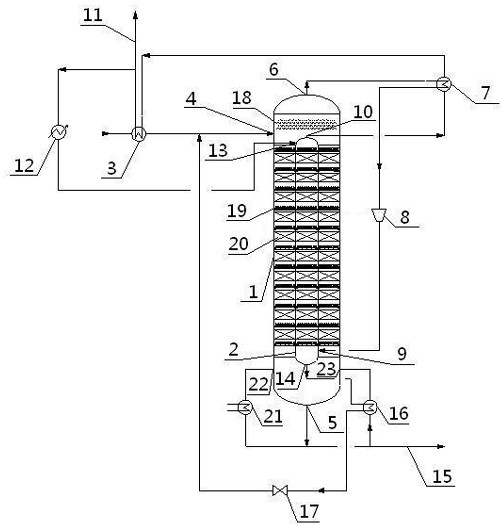

[0032] This embodiment discloses a rectification device with internal energy integration:

[0033] The rectification device includes a rectification tower with an inner and outer double-layer tower body, the outer tower body 1 is a stripping section, and the inner tower body 2 is a rectification section, which is arranged at the feed inlet I4 on the upper part of the outer tower body 1 The feed preheater 3 is externally connected, and the bottom of the outer tower body 1 is provided with a liquid outlet I5, a part of which is respectively connected to the discharge pipe 15 at the bottom of the tower and connected to the feed port V23 at the bottom of the outer tower body 1 through a reboiler 16 , the other part is connected to the feed port IV 22 located at the bottom of the outer tower body 1 through the auxiliary reboiler 21; the top of the outer tower body 1 is also provided with a gas outlet I6, which is connected to the compressor inlet superheater 7 and the compressor in ...

Embodiment 2

[0036] This embodiment discloses the method utilizing the device of embodiment 1 to carry out rectification:

[0037] After the feed is heated by the feed preheater 3, it enters the outer tower body 1 of the rectification tower through the feed inlet I4 for gas-liquid exchange. After the liquid phase is separated, the gas outlet I6 enters the compressor 8 through the compressor inlet superheater 7 to increase the pressure, and then enters the bottom of the inner tower body 2 through the feed inlet II9 to provide reboiling heat for the inner tower body 2; A part of the bottom liquid phase of the outer tower body 1 is discharged from the bottom discharge pipe 15 through the liquid outlet I5 and returned to the bottom of the outer tower body 1 by the feed inlet V23 after passing through the reboiler 16, which is the outer tower body 1 Provide reboil heat, part of which is returned to the bottom of the outer tower body 1 through the feed port IV 22 after the auxiliary reboiler 21,...

Embodiment 3

[0039] The present embodiment provides a kind of concrete process parameter and the result that utilize the method for embodiment 2 to carry out rectification:

[0040] The feed of the rectification tower is benzene-toluene system, the feed amount is 2000kg / h, the feed composition is 50% (wt%) benzene and 50% (wt%) toluene, the feed is fed at room temperature, and the feed preheater After preheating 3, the thermal condition of the feed is bubble point feed. The inner tower body 2 and the outer tower body 1 of the rectification tower are equipped with 10 layers of packing layers 20, the outer tower body 1 has an operating pressure of 1 atm, the operating temperature is 91 ° C, and the inner layer tower body 2 has an operating pressure of 3 atm. The operating temperature is 120° C., and the compression ratio of the compressor 8 is 3. The output of the tower top discharge pipe 11 is 1000kg / h, composed of 99.5% (wt%) benzene and 0.5% (wt%) toluene; the output of the tower bottom ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com