A reforming pretreatment system, reforming pretreatment method and application

A pretreatment and prehydrogenation technology, applied in the treatment of hydrocarbon oil, hydrotreating process, petroleum industry, etc., can solve the problems of incomplete heat exchange, low energy utilization efficiency, large efficiency loss, etc., and achieve energy saving effect Obviously, the effect of reducing the loss of effective energy and saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

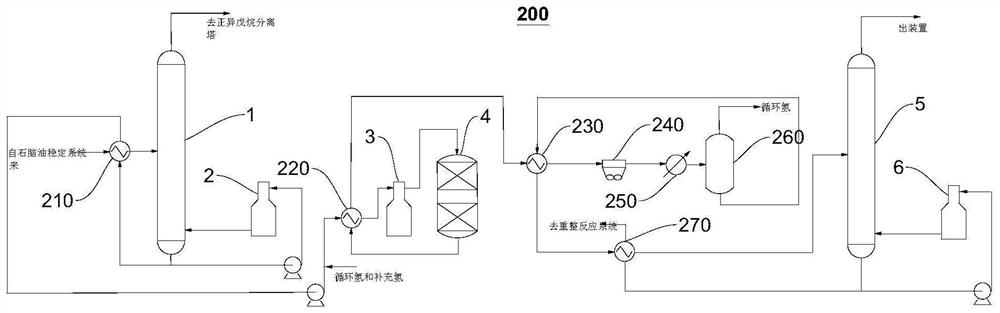

[0048] This embodiment provides an existing reforming pretreatment system 200, refer to figure 1 As shown, taking the 840,000 tons / year continuous reforming raw material pretreatment system of a refinery as an example, the pretreatment system of this device adopts the process mode of "fractionation first and then hydrogenation". It includes pre-fractionation tower feed heat exchanger 210, pre-fractionation tower 1, pre-fractionation tower reboiler 2, pre-hydrogenation feed heat exchanger 220, pre-hydrogenation heating furnace 3, pre-hydrogenation reactor 4, Stripper feed heat exchanger 230, prehydrogenation product air cooler 240, prehydrogenation product water cooler 250, prehydrogenation gas-liquid separation tank 260, stripper bottom heat exchanger 270, stripper 5 and stripper Tower kettle reboiler 6.

[0049] refer to figure 1 As shown, the naphtha raw material from the naphtha stabilization system first passes through the feed heat exchanger 210 of the pre-fractionation...

Embodiment 2

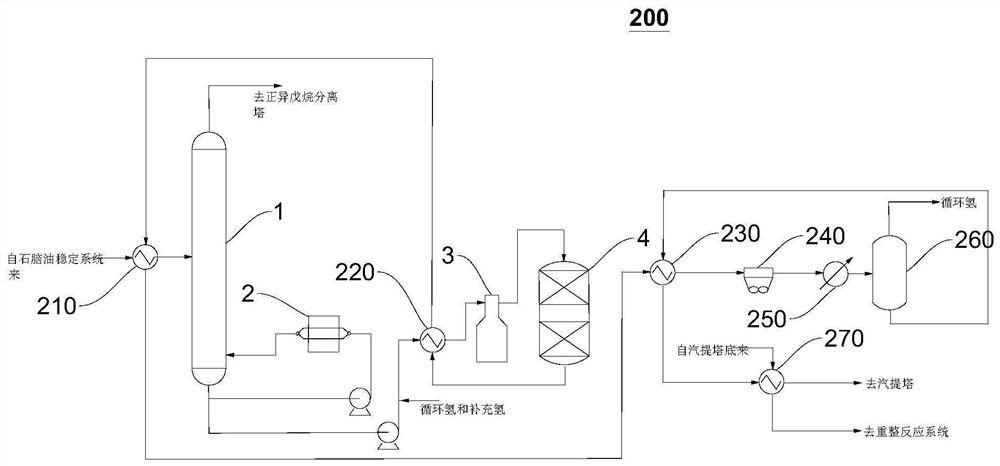

[0058] This embodiment provides a reforming pretreatment system 200 provided by the present invention, refer to figure 2 As shown, taking the 840,000 tons / year continuous reforming raw material pretreatment system of a refinery as an example, the pretreatment system of this device adopts the process mode of "fractionation first and then hydrogenation". It includes pre-fractionation tower feed heat exchanger 210, pre-fractionation tower 1, pre-fractionation tower reboiler 2, pre-hydrogenation feed heat exchanger 220, pre-hydrogenation heating furnace 3, pre-hydrogenation reactor 4, Stripper feed heat exchanger 230 , prehydrogenation product air cooler 240 , prehydrogenation product water cooler 250 , prehydrogenation gas-liquid separation tank 260 , stripper bottom heat exchanger 270 .

[0059] refer to figure 2 As shown, the naphtha raw material from the naphtha stabilization system first passes through the pre-fractionator feed heat exchanger 210 and the pre-hydrogenation ...

experiment example 1

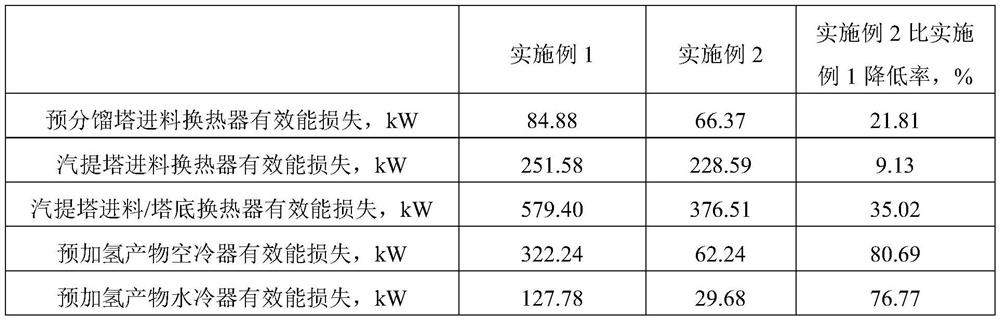

[0067] See Table 1 and Table 2 for comparison of energy consumption and effective energy loss of the methods and devices provided in Embodiment 1 and Embodiment 2.

[0068] Table 1 Comparison of heat exchange loads between Example 1 and Example 2.

[0069] Example 1 Example 2 Increase / decrease, % Prefractionator feed heat exchanger load, kW 902.94 902.94 0.00 Stripper feed heat exchanger load, kW 1450.42 3029.51 -108.87 Stripper feed / bottom heat exchanger load, kW 8423.68 6641.38 21.16 Air cooler load of pre-hydrogenated product, kW 2477.61 1092.52 55.90 Pre-hydrogenation product water cooler load, kW 1878.43 785.72 58.17 Pre-fractionation column reboiler, kW 8536.00 0.00 100.00 Prehydrogenation furnace, kW 3194.00 2291.06 28.27

[0070] Table 2 Example 1 and Example 2 comparison of exergy loss.

[0071]

[0072] It can be seen from Table 1 that the heat exchange load of the feed heat exchanger 210 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com