Supercritical rankine cycle power generation system with two transverse stages and one longitudinal stage

A technology of Rankine cycle and power generation system, applied in the field of Rankine cycle power generation system, can solve the problems of large temperature difference between cold and hot flow, low exergy efficiency of working medium evaporator, affecting the net output power of the system, etc., to reduce energy and simple structure. , the effect of stable system operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The following examples can enable those skilled in the art to understand the present invention more comprehensively, but the present invention is not limited to the scope of the described examples.

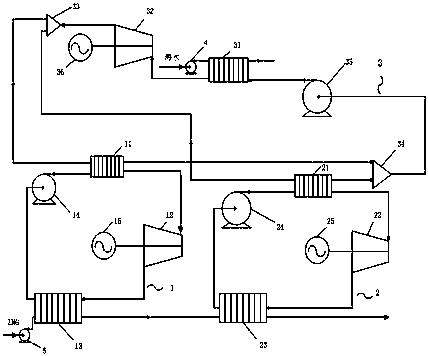

[0019] Such as figure 1 A supercritical horizontal two-pole vertical one-stage Rankine cycle power generation system shown includes an LNG circulation pump 5 and a seawater pump 4 .

[0020] Also includes horizontally juxtaposed

[0021] A primary power generating unit 1, which includes a primary evaporator 11, a primary steam turbine 12, a primary condenser 13, a primary working medium pump 14, and a primary working medium pump 14 connected in sequence to form a closed loop through pipelines, and in the closed loop Circulating primary power generation working fluid, wherein, the primary steam turbine 12 drives the first electric motor 15 to work, and the two ends of the primary evaporator 11 respectively have two primary heat source input ends and two primary heat source ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com