A coal chemical power polygeneration system based on calcium-based compounds

A compound and coal chemical technology, which is applied in the field of coal chemical power polygeneration system based on calcium-based compounds, can solve the problems of high energy consumption and large pollution of calcium carbide acetylene, and achieve the advantages of improving power generation efficiency, reducing emissions and saving processing costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

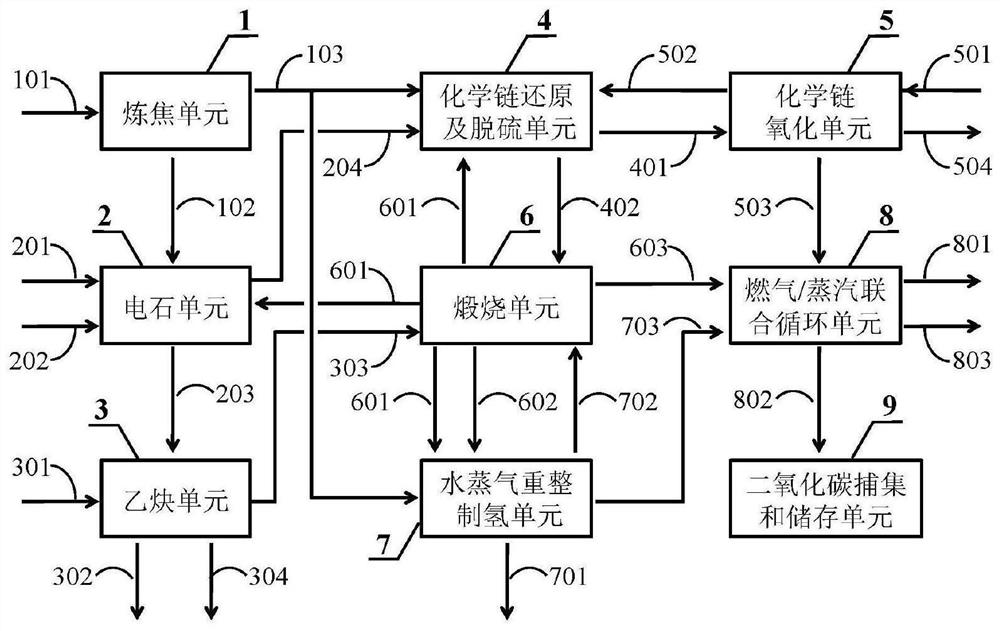

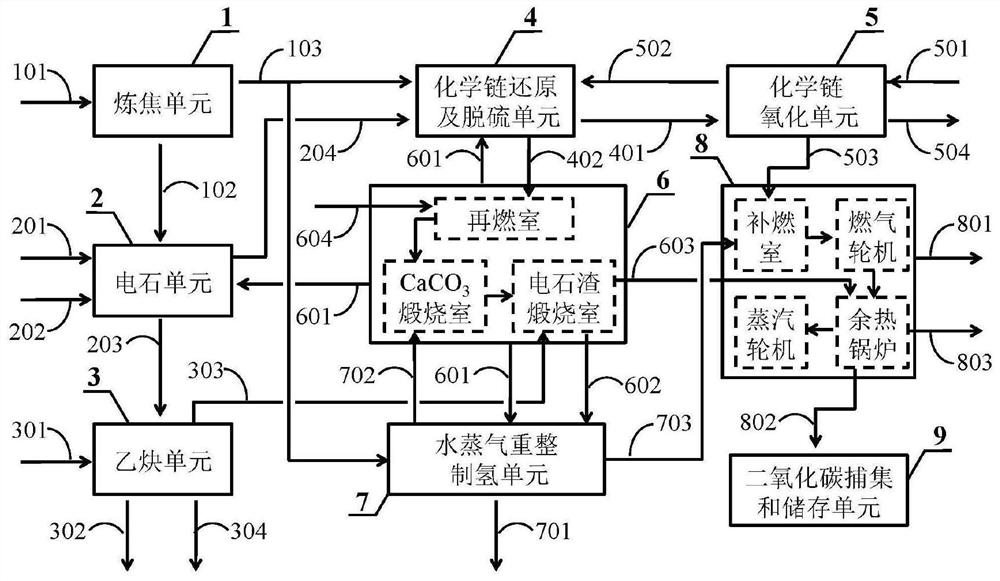

[0046] A specific embodiment of a coal-based chemical power polygeneration system based on calcium-based compounds, wherein the steam reforming hydrogen production unit 7 is in the operating mode, and the specific system flow is as follows figure 2 As shown, the description is as follows:

[0047] (1) Coal passes through the coking unit 1 to produce coke 102 , which is input into the calcium carbide unit 2 . Part of the by-product coke oven gas 103 directly enters the chemical looping reduction and desulfurization unit 4 for chemical looping combustion without cooling and purification treatment, and the other part enters the steam reforming hydrogen production unit 7 .

[0048](2) In the calcium carbide unit 2, the coke 102, the input quicklime 201 and the CaO 601 obtained after calcining calcium carbide slag are used in the closed calcium carbide furnace to produce calcium carbide 203 and input to the acetylene unit 3 by electrothermal process. The required power 202 is pro...

Embodiment 2

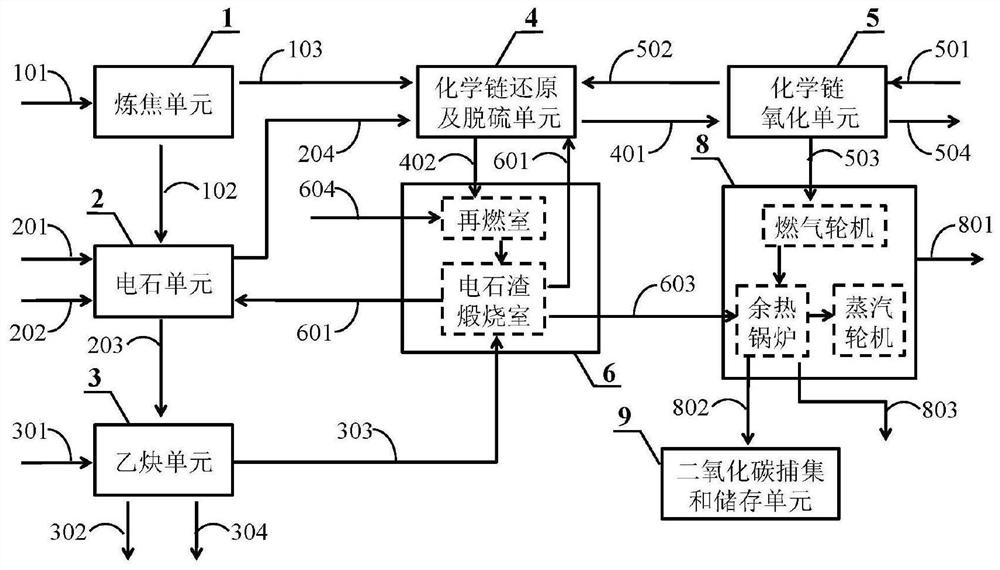

[0060] A specific embodiment of a coal-based chemical power polygeneration system based on calcium-based compounds, wherein the steam reforming hydrogen production unit 7 is in a non-operation mode, and the polygeneration system does not produce hydrogen. The specific system process is as image 3 As shown, the description is as follows:

[0061] (1) Coal passes through the coking unit 1 to produce coke 102 , which is input into the calcium carbide unit 2 . The by-product coke oven gas 103 directly enters the chemical looping reduction and desulfurization unit 4 for chemical looping combustion without cooling and purification treatment.

[0062] (2) In the calcium carbide unit 2, the coke 102, the input quicklime 201 and the CaO 601 obtained after calcining calcium carbide slag are used in the closed calcium carbide furnace to produce calcium carbide 203 and input to the acetylene unit 3 by electrothermal process. The required power 202 is provided by an external grid. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com