Compression condensation system with ejector

An ejector and condenser technology, applied in the field of physics, can solve the problems of long operation time, large condensation load, complicated operation, etc., and achieve the effect of short operation time, less condensation load, and reduced condensation load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

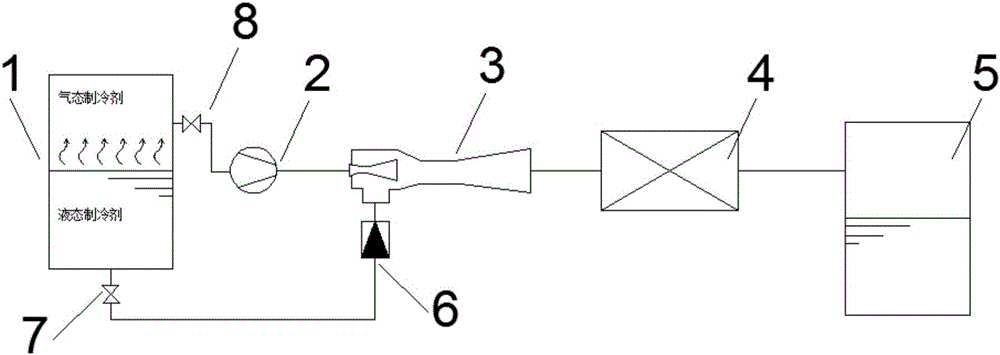

[0023] Such as figure 1 As shown, the present invention provides a refrigerant recovery system with an ejector, including a recovered container 1, a refrigeration compressor 2, an ejector 3, a condenser 4, and a recovery container 5. The recovered container 1 and a first Two shut-off valves 8 are connected, the second shut-off valve 8 is connected with the refrigeration compressor 2, the refrigeration compressor 2 is connected with the ejector 3, and the ejector 3 is connected with the The condenser 4 is connected, the condenser 4 is connected to the recovery container 5, the ejector 3 is also connected to a one-way valve 6, and the one-way valve 6 is connected to a first stop valve 7 , The first shut-off valve 7 is connected to the recovered container 1.

[0024] When there is liquid refrigerant in the recovered container 1, such as figure 1 As shown, valves 7 and 8 are open, the suction pipe of the refrigeration compressor 2 is connected to the gas pipe of the recovered contain...

Embodiment 2

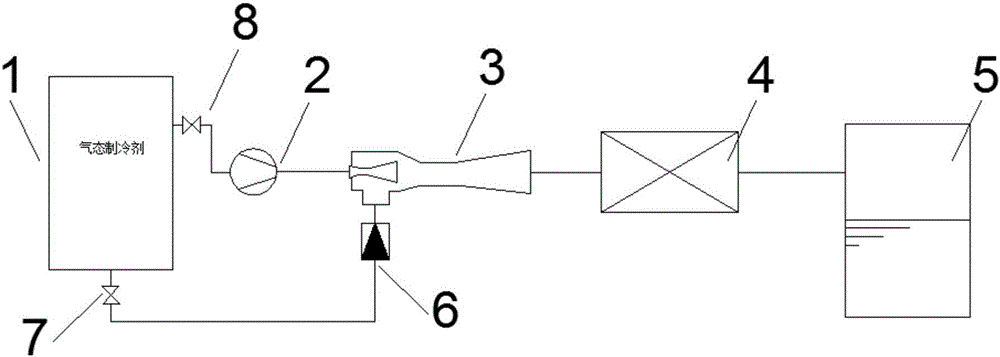

[0029] When there is only refrigerant wet vapor or dry vapor in the recovered container 1, such as figure 2 Shown.

[0030] The connection mode and operating principle of the system are the same as those of the first embodiment. The difference is that the substance injected by the ejector 3 is a gaseous refrigerant at this time.

[0031] Although the ejector 3 no longer injects liquid refrigerant, the exhaust from the compressor 2 injects the gaseous refrigerant in the recovered container 1. The injected refrigerant does not need to be compressed into a high temperature and high pressure state by the compressor 2, which can be compared with the embodiment 1 The same beneficial effect.

Embodiment 3

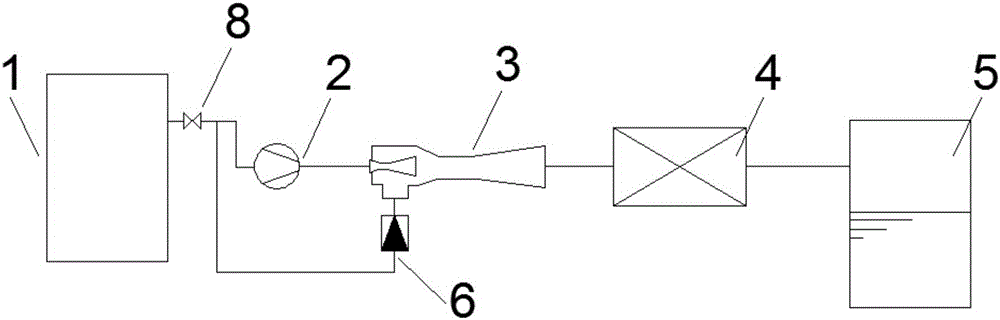

[0033] Such as image 3 As shown, the present invention also provides another refrigerant recovery system with ejector, including the recovered container 1, the refrigeration compressor 2, the ejector 3, the condenser 4, and the recovery container 5. The recovered container 1 and A second stop valve 8 is connected, the second stop valve 8 is connected to the refrigeration compressor 2, the refrigeration compressor 2 is connected to the ejector 3, and the ejector 3 is connected to the The condenser 4 is connected, the condenser 4 is connected with the recovery container 5, the ejector 3 is also connected with a one-way valve 6, and the one-way valve 6 is connected to the second shut-off valve 8. The pipeline communicates with the refrigeration compressor 2.

[0034] When the recovered container 1 does not have a liquid pipe, or it is inconvenient for liquid recovery, the ejector 3’s ejector inlet is connected in parallel with the refrigeration compressor 2 suction pipe, and the ot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com